Crack initiators are microscopic defects or stress concentrators within a material that serve as the starting points for crack formation under mechanical loading. These imperfections, such as inclusions, voids, or surface scratches, significantly influence the fatigue life and structural integrity of components. Explore the full article to understand how managing crack initiators can enhance your material performance and durability.

Table of Comparison

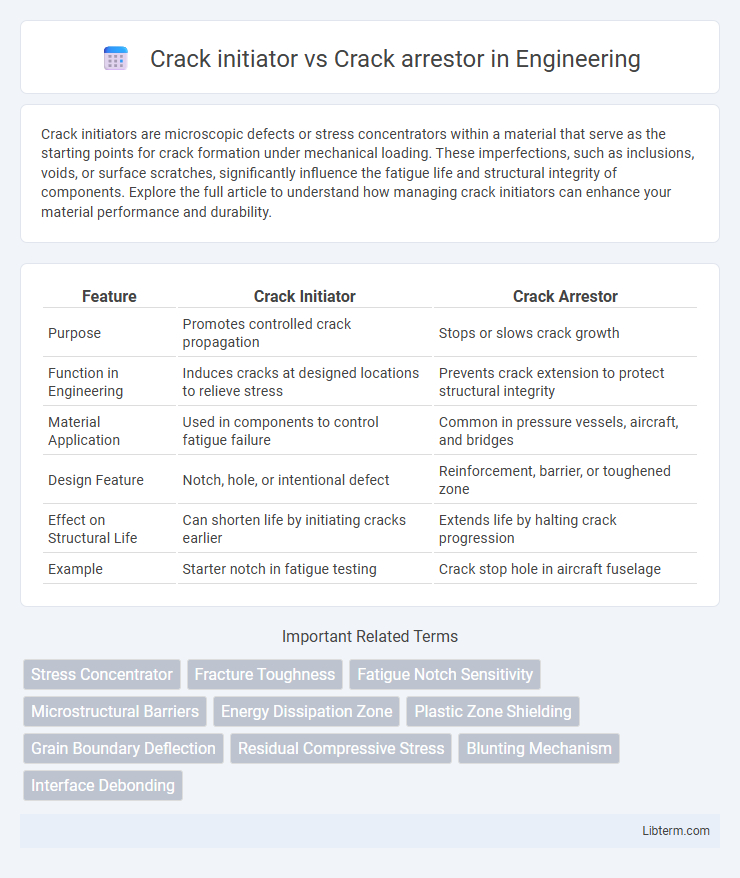

| Feature | Crack Initiator | Crack Arrestor |

|---|---|---|

| Purpose | Promotes controlled crack propagation | Stops or slows crack growth |

| Function in Engineering | Induces cracks at designed locations to relieve stress | Prevents crack extension to protect structural integrity |

| Material Application | Used in components to control fatigue failure | Common in pressure vessels, aircraft, and bridges |

| Design Feature | Notch, hole, or intentional defect | Reinforcement, barrier, or toughened zone |

| Effect on Structural Life | Can shorten life by initiating cracks earlier | Extends life by halting crack progression |

| Example | Starter notch in fatigue testing | Crack stop hole in aircraft fuselage |

Introduction to Crack Initiators and Crack Arrestors

Crack initiators are structural features or material flaws that serve as the origin points for crack formation under stress, often including notches, sharp corners, or inclusions. Crack arrestors are design elements or materials engineered to halt or slow crack propagation, such as crack stoppers, barriers, or specialized composites. Understanding the roles of crack initiators and arrestors is crucial in fracture mechanics to improve structural integrity and prevent catastrophic failure.

Understanding Crack Formation in Materials

Crack initiators are microscopic defects or stress concentrators such as inclusions, voids, or surface scratches that serve as the origin points for crack formation in materials. Crack arrestors, on the other hand, are mechanisms or design features like grain boundaries, phase interfaces, or compressive residual stresses that impede crack propagation and enhance material toughness. Understanding the interplay between crack initiators and arrestors is critical for improving fatigue resistance and extending the service life of structural components.

What is a Crack Initiator?

A crack initiator is a stress concentration site or material flaw where micro-cracks begin to form under cyclic loading or environmental factors. These initiation points, such as sharp corners, notches, or inclusions, significantly reduce the fatigue life of materials by enabling crack propagation. Understanding crack initiators is critical for designing components that resist fatigue failure and enhance structural durability.

Common Types and Sources of Crack Initiators

Common types of crack initiators include microstructural defects, surface corrosion, fatigue loading, and stress concentrators such as notches or sharp corners. Surface imperfections like scratches, pits, or inclusions often serve as primary crack initiation sites by concentrating stress and facilitating crack nucleation. Crack arrestors, designed to stop or slow crack propagation, may incorporate features like crack stoppers, material toughening agents, or geometric modifications to reduce stress intensity and prevent further crack growth.

Defining Crack Arrestors and Their Function

Crack arrestors are engineered components designed to halt the propagation of cracks in structures by redistributing stresses and mitigating crack tip energy. Unlike crack initiators, which are points or defects where cracks originate due to stress concentration, crack arrestors function to enhance the material's fracture toughness and prevent catastrophic failure. These devices are critical in industries such as aerospace and pipeline engineering, where maintaining structural integrity under cyclic loading is essential.

Key Differences: Crack Initiator vs Crack Arrestor

A crack initiator is typically a stress concentrator such as a notch, inclusion, or surface defect that causes the onset of crack growth under cyclic or static loading conditions. In contrast, a crack arrestor is a design feature or material barrier that stops or slows down the propagation of an existing crack, preventing catastrophic failure. Key differences include function (initiation vs. stopping the crack), location (origin point vs. along crack path), and application (materials susceptible to crack initiation vs. structural elements designed for crack containment).

Material Selection for Crack Prevention

Selecting materials with high fracture toughness and resistance to crack propagation is essential for effective crack initiators and crack arrestors. Crack initiators require materials that minimize stress concentration and resist crack nucleation, often utilizing alloys with refined grain structures and enhanced ductility. Crack arrestors demand materials capable of absorbing energy and slowing crack growth, typically featuring microstructures that promote crack deflection and energy dissipation to prevent catastrophic failure.

Engineering Strategies to Minimize Crack Initiation

Crack initiators are microscopic defects or stress concentrators where fractures begin, while crack arrestors are design features or materials that prevent further crack propagation in engineering components. Minimizing crack initiation involves optimizing material selection with high fracture toughness, implementing surface treatments such as shot peening or coating to reduce residual stresses, and employing precise stress analysis to eliminate geometric discontinuities. Advanced non-destructive evaluation (NDE) techniques enable early detection of potential crack initiation sites, allowing for preventive maintenance and design modifications.

Techniques for Effective Crack Arresting

Crack initiators and crack arrestors play distinct roles in material failure, where crack initiators are flaws or stress concentrators that trigger crack formation, while crack arrestors are designed elements or techniques that halt crack propagation. Effective crack arresting techniques include introducing microstructural barriers such as grain boundaries or phase interfaces, employing toughening mechanisms like crack deflection and bridging, and optimizing material composition to enhance fracture toughness. Advanced methods also involve using fiber reinforcements and engineered residual stresses to dissipate crack energy and prevent catastrophic failure in critical structures.

Real-World Applications and Industry Examples

Crack initiators, such as material defects or stress concentrators, often trigger failures in aerospace components and automotive parts, where fatigue life is critical. Crack arrestors, including crack stoppers or arrest holes, are integral in pipeline engineering and aircraft fuselage design to prevent crack propagation and enhance structural integrity. In civil engineering, steel reinforcements act as crack arrestors to control crack growth in concrete structures, extending their service life under dynamic loads.

Crack initiator Infographic

libterm.com

libterm.com