Allowable stress is the maximum stress a material or structural component can safely withstand under specified conditions without failure. It is determined by dividing the material's yield or ultimate strength by a suitable factor of safety, ensuring structural integrity during operation. Discover more about how allowable stress impacts design and safety in the rest of the article.

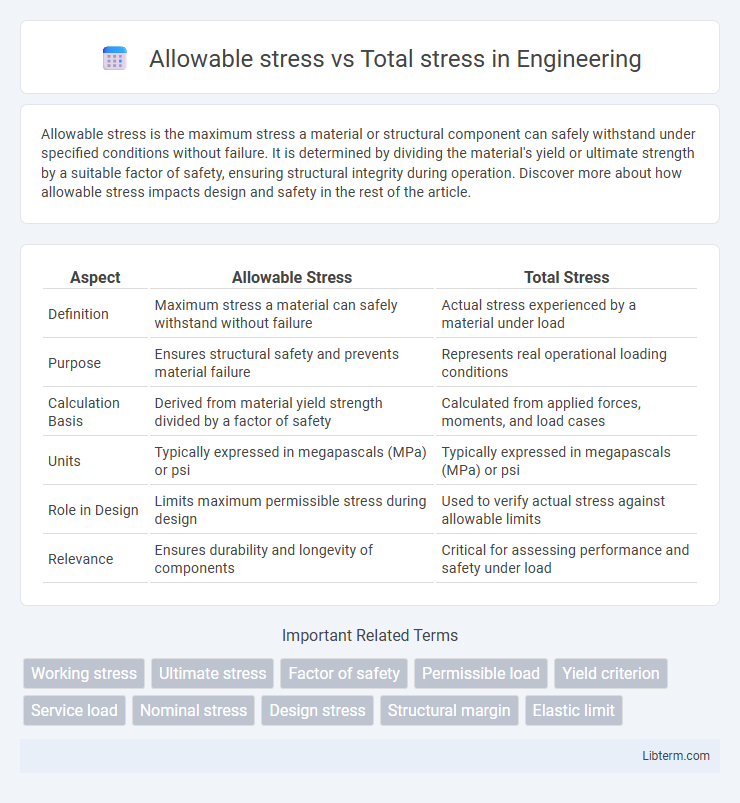

Table of Comparison

| Aspect | Allowable Stress | Total Stress |

|---|---|---|

| Definition | Maximum stress a material can safely withstand without failure | Actual stress experienced by a material under load |

| Purpose | Ensures structural safety and prevents material failure | Represents real operational loading conditions |

| Calculation Basis | Derived from material yield strength divided by a factor of safety | Calculated from applied forces, moments, and load cases |

| Units | Typically expressed in megapascals (MPa) or psi | Typically expressed in megapascals (MPa) or psi |

| Role in Design | Limits maximum permissible stress during design | Used to verify actual stress against allowable limits |

| Relevance | Ensures durability and longevity of components | Critical for assessing performance and safety under load |

Introduction to Allowable Stress and Total Stress

Allowable stress is the maximum stress that a material or structural component can safely withstand without failure, determined by dividing the ultimate or yield strength by a safety factor. Total stress refers to the actual stress experienced by the material due to applied loads, including axial, bending, and shear stresses. Understanding the difference between allowable stress and total stress is crucial for engineering design to ensure safety and structural integrity under operating conditions.

Defining Allowable Stress

Allowable stress is the maximum stress that a material or structural component can safely withstand under specified loading conditions without failure, incorporating a safety factor to account for uncertainties. It is derived by dividing the material's yield strength or ultimate strength by a safety factor, ensuring structural integrity throughout the design life. Total stress, in contrast, represents the actual stress experienced by the component under applied loads, including axial, shear, and bending stresses.

Understanding Total Stress

Total stress refers to the actual stress experienced by a material or structure under load, encompassing all forces applied, including axial, shear, and bending stresses. It is critical to compare total stress against allowable stress, which is the maximum permitted stress level determined by safety codes to prevent failure. Understanding total stress involves accurately calculating combined stresses to ensure structural integrity and compliance with design limits.

Key Differences Between Allowable Stress and Total Stress

Allowable stress refers to the maximum stress a material can safely withstand under design conditions without failure, typically derived from material yield strength divided by a safety factor. Total stress represents the actual stress experienced by the material due to applied loads, including forces such as tension, compression, shear, and bending. The key difference lies in allowable stress being a calculated limit ensuring structural safety, whereas total stress is the real-time stress encountered during operation.

Importance of Allowable Stress in Engineering Design

Allowable stress serves as a critical safety threshold in engineering design, ensuring that materials and structures perform reliably under expected loads without failure. It accounts for factors such as material properties, safety factors, and environmental conditions, providing a controlled limit significantly lower than total or ultimate stress levels. Prioritizing allowable stress prevents structural damage, extends lifespan, and upholds safety standards across engineering applications.

Total Stress Calculation Methods

Total stress calculation methods involve summing the applied loads and environmental influences acting on a structure, including axial, bending, torsional, and shear stresses. Techniques such as finite element analysis (FEA) and classical strength of materials formulas are commonly employed to evaluate these combined stresses accurately. Understanding total stress is essential for ensuring that the calculated stress does not exceed the allowable stress, thus maintaining structural integrity and safety.

Factors Affecting Allowable and Total Stress

Allowable stress depends on material properties, safety factors, and environmental conditions, ensuring structural integrity under operational loads. Total stress accounts for all applied forces, including axial, shear, and bending stresses, influenced by load type, magnitude, and distribution. Temperature, corrosion, and material degradation significantly affect both allowable and total stress values, impacting design and safety assessments.

Practical Applications in Civil and Structural Engineering

Allowable stress represents the maximum stress a material or structural component can withstand safely under service conditions, incorporating safety factors to prevent failure. Total stress refers to the actual stress exerted on a structure due to applied loads, including dead loads, live loads, wind loads, and seismic forces. In civil and structural engineering, comparing total stress with allowable stress ensures designs maintain structural integrity, optimize material use, and comply with safety codes like AISC and Eurocode standards.

Common Mistakes When Comparing Allowable vs Total Stress

Confusing allowable stress with total stress often leads to miscalculations in structural design, as allowable stress incorporates safety factors and material properties while total stress represents the actual applied loads. Engineers frequently overlook the importance of safety margins embedded in allowable stress, resulting in unsafe or overly conservative designs. Misinterpreting these stresses can cause either structural failure or unnecessary material costs, stressing the need for accurate differentiation in stress analysis.

Conclusion: Choosing the Right Stress Parameter

Selecting the appropriate stress parameter hinges on application safety and material performance criteria. Allowable stress ensures structural integrity by incorporating safety factors against material yield or failure limits. Total stress provides exact load values but lacks inherent safety considerations, making allowable stress essential for reliable engineering design.

Allowable stress Infographic

libterm.com

libterm.com