A tappet is a crucial component in internal combustion engines, responsible for transferring motion from the camshaft to the valves, ensuring precise timing and efficient engine performance. Proper maintenance of the tappet can prevent wear and noise, prolonging your engine's lifespan and enhancing fuel efficiency. Discover how understanding tappets can optimize your vehicle's performance in the rest of this article.

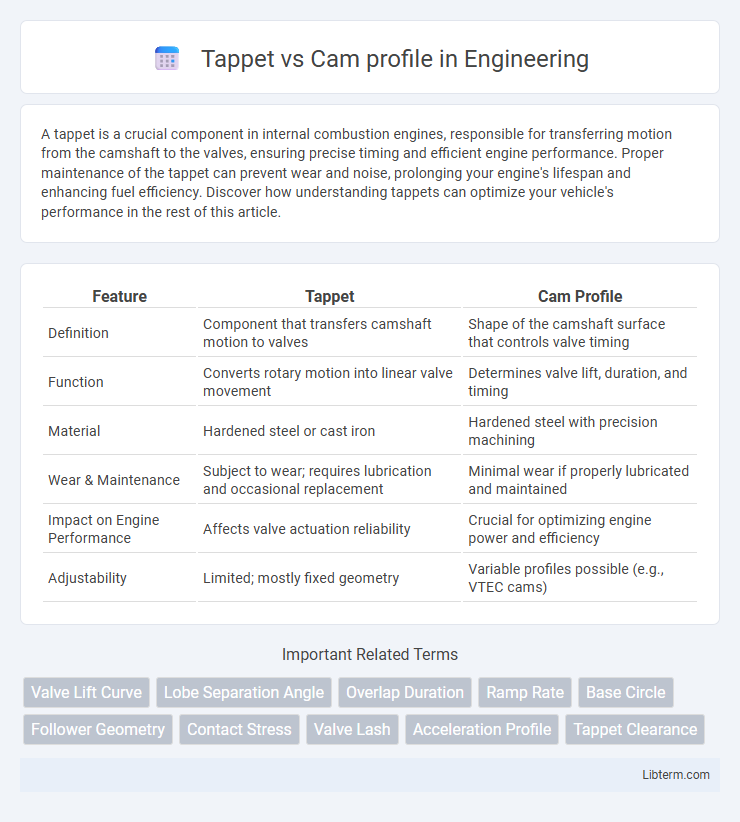

Table of Comparison

| Feature | Tappet | Cam Profile |

|---|---|---|

| Definition | Component that transfers camshaft motion to valves | Shape of the camshaft surface that controls valve timing |

| Function | Converts rotary motion into linear valve movement | Determines valve lift, duration, and timing |

| Material | Hardened steel or cast iron | Hardened steel with precision machining |

| Wear & Maintenance | Subject to wear; requires lubrication and occasional replacement | Minimal wear if properly lubricated and maintained |

| Impact on Engine Performance | Affects valve actuation reliability | Crucial for optimizing engine power and efficiency |

| Adjustability | Limited; mostly fixed geometry | Variable profiles possible (e.g., VTEC cams) |

Introduction to Tappet and Cam Profile

The tappet, also known as a valve lifter, is a crucial engine component positioned between the camshaft and the valve, responsible for translating cam profile motion into valve actuation. The cam profile refers to the specific shape and contour of the camshaft lobes, designed to control valve opening duration, lift, and timing for optimal engine performance. Understanding the interaction between tappet and cam profile is essential for tuning engine efficiency, power output, and emissions control.

What is a Tappet?

A tappet, also known as a valve lifter, is a cylindrical component in an internal combustion engine that transfers motion from the camshaft to the engine valves, ensuring precise timing and valve movement. It rides on the cam profile, which is the camshaft's specially shaped surface designed to convert rotational motion into linear motion. The tappet's efficiency in following the cam profile directly impacts engine performance, noise, and wear.

Understanding Cam Profile Design

Cam profile design directly influences valve timing, lift, and duration, critical factors in engine performance and efficiency. Tappet type interacts with the cam profile, where a flat-face tappet smooths contact and reduces wear, while a roller tappet minimizes friction, enabling more aggressive cam profiles for higher power output. Understanding the relationship between cam profile geometry and tappet design optimizes valve train dynamics and enhances overall engine durability and performance.

Types of Tappets in Engines

Tappets in engines are primarily classified into flat tappets, roller tappets, and mushroom tappets, each designed to interact with the cam profile differently for optimized valve timing and reduced wear. Flat tappets have a flat surface that directly contacts the camshaft, suitable for traditional engines, while roller tappets incorporate a rolling element to minimize friction and improve efficiency in high-performance applications. Mushroom tappets, shaped like a mushroom cap, provide a balance between durability and smooth operation, often used in older or specialized engine designs.

Types of Cam Profiles

Cam profiles are essential in controlling valve timing and motion in internal combustion engines, with common types including flat-tappet, roller, and mushroom cams. Flat-tappet cams feature a broad, flat surface interacting with the tappet, offering simplicity but higher friction and wear compared to roller cams, which use a rolling follower to reduce friction and improve efficiency. Mushroom cams, less common, provide a mix of durability and performance by combining flat and curved surfaces for specific valve lift and duration characteristics.

Key Differences: Tappet vs Cam Profile

The tappet, also known as a valve lifter, directly contacts the cam profile to convert rotational motion into linear motion, enabling valve operation in an engine. The cam profile is the precise contour on the camshaft designed to control the timing, lift, and duration of valve opening through its interaction with the tappet. Key differences include that the tappet acts as a physical interface translating camshaft rotation; the cam profile determines engine performance characteristics by shaping valve motion.

Impact on Engine Performance

The tappet and cam profile directly influence valve timing, lift, and duration, which are critical for optimizing engine airflow and combustion efficiency. A well-designed cam profile with precise tappet clearance ensures maximum power output, improved fuel economy, and reduced emissions by optimizing valve opening and closing events. Conversely, improper tappet adjustment or a mismatched cam profile can lead to reduced performance, increased wear, and potential engine damage.

Advantages and Disadvantages

Tappet systems offer simpler design and reduced valve train noise but may suffer from increased wear and less precise valve timing compared to cam profile mechanisms. Cam profiles enable accurate valve lift and timing control, improving engine efficiency and performance, yet they entail higher manufacturing complexity and maintenance requirements. Choosing between tappet and cam profile depends on balancing durability, precision, and cost-effectiveness for specific engine applications.

Applications in Modern Engines

Tappets in modern engines serve primarily to transfer motion from cam profiles to valves, enhancing durability and reducing noise in high-performance applications. Cam profiles are engineered to optimize valve timing and lift, crucial for efficient combustion and power output in advanced engines. The combination of tailored cam profiles with precision tappets improves fuel efficiency and emissions control in contemporary automotive and motorcycle powertrains.

Choosing the Right System for Your Engine

Selecting the optimal tappet or cam profile system depends on engine performance goals and durability requirements. Hydraulic tappets reduce maintenance by automatically adjusting valve clearance, while solid tappets and custom cam profiles offer precise control for high-performance applications. Analyzing engine speed, load conditions, and desired power output helps determine the best combination for efficiency and longevity.

Tappet Infographic

libterm.com

libterm.com