Diesel engines are renowned for their fuel efficiency and durability, making them ideal for heavy-duty vehicles and long-distance travel. They operate by compressing air to ignite fuel, resulting in higher torque and better performance under load compared to gasoline engines. Discover more about how diesel technology can influence your vehicle's power and economy by reading the full article.

Table of Comparison

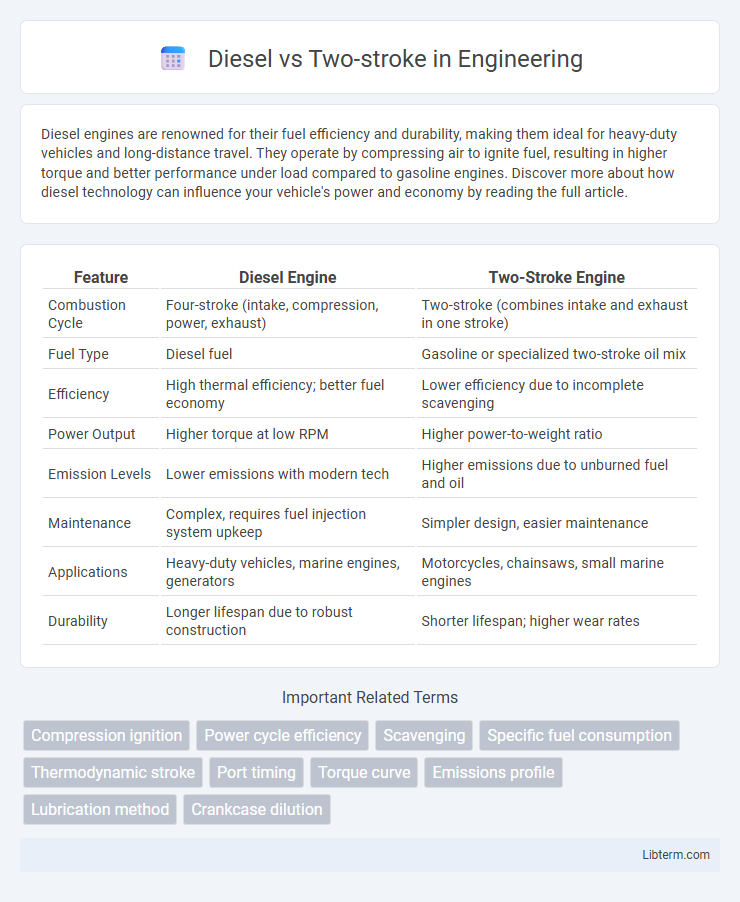

| Feature | Diesel Engine | Two-Stroke Engine |

|---|---|---|

| Combustion Cycle | Four-stroke (intake, compression, power, exhaust) | Two-stroke (combines intake and exhaust in one stroke) |

| Fuel Type | Diesel fuel | Gasoline or specialized two-stroke oil mix |

| Efficiency | High thermal efficiency; better fuel economy | Lower efficiency due to incomplete scavenging |

| Power Output | Higher torque at low RPM | Higher power-to-weight ratio |

| Emission Levels | Lower emissions with modern tech | Higher emissions due to unburned fuel and oil |

| Maintenance | Complex, requires fuel injection system upkeep | Simpler design, easier maintenance |

| Applications | Heavy-duty vehicles, marine engines, generators | Motorcycles, chainsaws, small marine engines |

| Durability | Longer lifespan due to robust construction | Shorter lifespan; higher wear rates |

Introduction: Diesel vs Two-Stroke Engines

Diesel engines operate on compression ignition, delivering higher fuel efficiency and torque compared to two-stroke engines, which rely on a simpler design with a single power stroke per cycle for faster power output. Two-stroke engines are widely used in lightweight applications like motorcycles and small machinery due to their compact size and high power-to-weight ratio. Diesel engines dominate heavy-duty sectors, offering durability, fuel economy, and lower emissions in comparison to traditional two-stroke designs.

Fundamental Differences in Engine Design

Diesel engines operate using compression ignition, where air is compressed to high temperatures before fuel injection, while two-stroke engines rely on a simpler combustion process with fuel-air mixture entering and exhaust gases exiting within two strokes of the piston. Diesel engines are typically heavier and more robust due to higher compression ratios and complex fuel injection systems, whereas two-stroke engines are lighter and designed for higher power-to-weight ratios but have less fuel efficiency. The explosion mechanics in diesel engines result in higher thermal efficiency, and two-stroke engines sacrifice efficiency for simplicity and higher rpm performance.

Combustion Processes Explained

Diesel engines operate using compression ignition, where air is compressed to a high temperature before fuel injection triggers combustion, resulting in efficient energy release and lower fuel consumption. Two-stroke engines rely on a combined intake and exhaust process, with fuel mixed with air entering the combustion chamber and ignited by a spark or compression, enabling power generation every revolution. The key difference lies in diesel's controlled fuel injection and high compression ratio versus the simpler intake and scavenging system of two-stroke engines, affecting their combustion efficiency and emissions.

Power Output and Efficiency Comparison

Diesel engines typically produce higher torque and better fuel efficiency compared to two-stroke engines due to their longer power strokes and higher compression ratios. Two-stroke engines often deliver more power-to-weight ratio and faster acceleration but consume more fuel and emit higher pollutants because of incomplete combustion cycles. Efficiency in diesel engines is superior in heavy-duty and continuous operation scenarios, while two-stroke engines favor lightweight and high-rev applications with comparatively lower fuel efficiency.

Fuel Economy and Consumption

Diesel engines generally offer superior fuel economy compared to two-stroke engines due to their higher thermal efficiency and leaner combustion process. Two-stroke engines consume more fuel as they mix oil with gasoline, leading to incomplete combustion and increased fuel waste. In applications where fuel consumption is critical, diesel engines provide longer operational times and lower fuel costs per horsepower-hour.

Emissions and Environmental Impact

Diesel engines emit higher levels of nitrogen oxides (NOx) and particulate matter compared to two-stroke engines, which typically release more unburned hydrocarbons and carbon monoxide due to incomplete combustion. Two-stroke engines, common in smaller vehicles and machinery, have a higher environmental impact because their design allows fuel-oil mixtures to escape unburned, contributing to air pollution and smog formation. Diesel engines, while cleaner in hydrocarbon emissions, require advanced after-treatment systems like diesel particulate filters (DPFs) and selective catalytic reduction (SCR) to mitigate their environmental impact effectively.

Maintenance and Longevity

Diesel engines typically require less frequent maintenance due to their robust construction and precise fuel injection systems, resulting in longer engine life compared to two-stroke engines. Two-stroke engines, with their simpler design and higher RPM operation, demand more regular maintenance such as spark plug replacement and carburetor cleaning to prevent fouling and wear. The longevity of diesel engines often surpasses two-stroke engines, as diesel combustion produces less engine wear and the engines are built to withstand higher compression ratios.

Applications in Industry and Transportation

Diesel engines dominate heavy-duty industrial machinery and long-haul transportation due to their high fuel efficiency and durability, especially in trucks, buses, and construction equipment. Two-stroke engines are commonly used in smaller-scale applications like motorcycles, marine outboard motors, and handheld power tools where lightweight and high power-to-weight ratios are critical. The choice between diesel and two-stroke technologies depends largely on performance requirements, emission regulations, and operational cost considerations in specific industrial or transport sectors.

Cost Analysis: Initial and Long-term Expenses

Diesel engines generally have higher initial costs due to complex fuel systems and heavier components, while two-stroke engines are less expensive to manufacture and purchase. Long-term expenses favor diesel engines because of better fuel efficiency, lower maintenance frequency, and longer lifespan, whereas two-stroke engines incur higher fuel consumption, increased oil use, and more frequent repairs. Considering total cost of ownership, diesel engines provide a more economical solution for sustained heavy-duty applications despite the upfront investment.

Conclusion: Choosing the Right Engine

Diesel engines provide superior fuel efficiency and durability, making them ideal for heavy-duty applications and long-term use. Two-stroke engines offer a lightweight design and higher power-to-weight ratio, suited for small machinery and portable equipment. Selecting the right engine depends on the specific needs of performance, fuel economy, maintenance, and operational environment.

Diesel Infographic

libterm.com

libterm.com