A butt joint is a fundamental woodworking or metalworking technique where two pieces are joined by simply aligning their flat ends together without any special shaping. This joint is easy to create but typically requires reinforcing methods such as screws, nails, or adhesives to enhance strength and durability. Discover more about how you can effectively use butt joints in your projects by reading the full article.

Table of Comparison

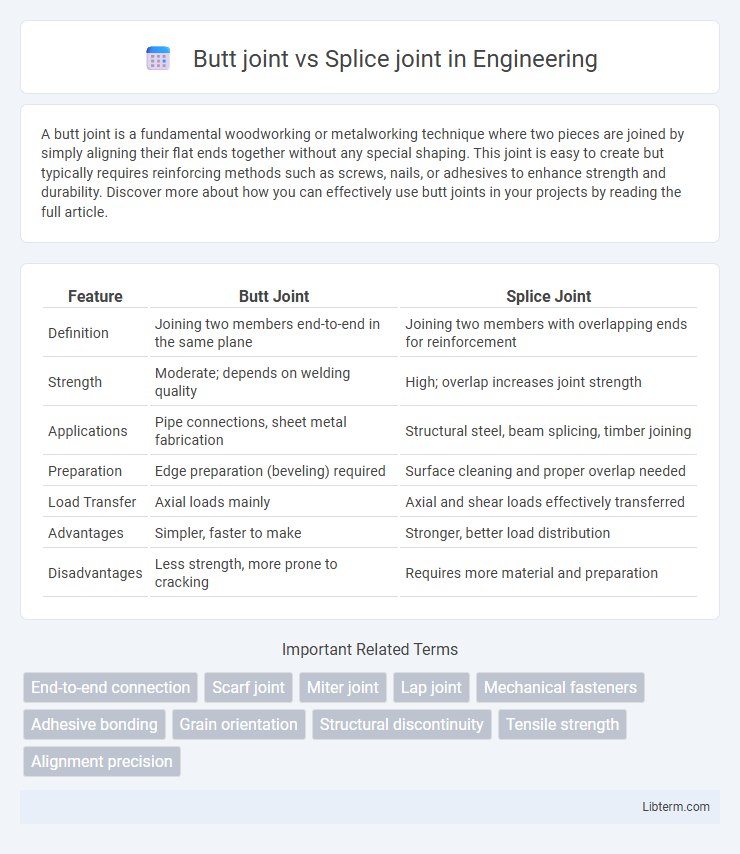

| Feature | Butt Joint | Splice Joint |

|---|---|---|

| Definition | Joining two members end-to-end in the same plane | Joining two members with overlapping ends for reinforcement |

| Strength | Moderate; depends on welding quality | High; overlap increases joint strength |

| Applications | Pipe connections, sheet metal fabrication | Structural steel, beam splicing, timber joining |

| Preparation | Edge preparation (beveling) required | Surface cleaning and proper overlap needed |

| Load Transfer | Axial loads mainly | Axial and shear loads effectively transferred |

| Advantages | Simpler, faster to make | Stronger, better load distribution |

| Disadvantages | Less strength, more prone to cracking | Requires more material and preparation |

Introduction to Butt and Splice Joints

Butt joints connect two pieces of material end-to-end without overlapping, commonly used in woodworking, metalworking, and construction for simple, straightforward connections. Splice joints join two pieces by overlapping or interlocking sections, increasing surface area for improved strength and alignment, often applied in structural beams and long material extensions. Understanding the distinction between these joints is essential for selecting the appropriate method based on load requirements and material properties.

Definition of Butt Joint

A butt joint is a simple, direct connection where two pieces of material, such as wood or metal, are joined end-to-end without overlapping or additional shaping, commonly used in woodworking and welding. This joint is characterized by the square ends of the components being pressed against each other, relying on adhesives, welding, or fasteners for strength. In contrast, a splice joint involves overlapping or interlocking sections to enhance structural integrity and often distributes stress more evenly.

Definition of Splice Joint

A splice joint is a method of joining two pieces of material end-to-end to extend their length, commonly used in woodworking and metalworking. Unlike a butt joint, where the ends are simply placed together without overlapping, a splice joint involves overlapping or interlocking the ends to create a stronger and more durable connection. This type of joint improves structural integrity by distributing stress over a larger area, making it ideal for applications requiring length extension and enhanced load-bearing capacity.

Structural Differences

Butt joints connect two pieces of material end-to-end without overlapping, relying primarily on external fasteners, adhesives, or welding for strength, making them simpler but generally weaker in load-bearing capacity. Splice joints overlap the ends of two components, increasing the contact area and distributing stress more evenly, which significantly enhances structural integrity and resistance to tension or bending forces. The overlapping nature of splice joints makes them ideal for extending lengths of beams or pipes where maintaining strength and alignment is critical.

Common Applications

Butt joints are commonly used in woodworking, metal fabrication, and construction for simple, fast, and cost-effective joins, particularly in framing, furniture, and panel assembly. Splice joints find frequent application in joining long sections of materials like wood, metal, or plastic, often in structural elements such as beams, pipes, and cables where extension and strength continuity are required. Both joints are essential in manufacturing and repair tasks, with butt joints favored for ease and splice joints for reinforced sectional connections.

Strength and Durability Comparison

Butt joints typically offer moderate strength and are easier to assemble but may require reinforcement for high-stress applications. Splice joints provide superior strength and durability by increasing the surface area for bonding or welding, making them ideal for structural components subjected to heavy loads. The enhanced load distribution in splice joints reduces the risk of joint failure over time compared to butt joints.

Ease of Fabrication and Installation

Butt joints offer straightforward fabrication and installation due to their simple end-to-end alignment, making them ideal for quick assembly and minimal preparation. Splice joints require more precise cutting and alignment of overlapping materials, increasing fabrication complexity but providing enhanced strength and surface area for bonding. In applications prioritizing speed and simplicity, butt joints excel, whereas splice joints are preferred where joint reinforcement and durability are critical.

Cost Implications

Butt joints typically incur lower initial costs due to simpler preparation and faster assembly, making them suitable for budget-conscious projects. Splice joints, while more expensive upfront because of extended labor and material requirements, offer enhanced strength and durability that can reduce long-term maintenance expenses. Choosing between these joints should balance immediate budget constraints with potential savings from improved joint performance over time.

Pros and Cons of Each Joint Type

Butt joints offer simplicity and ease of alignment, making them ideal for quick assembly, but they often lack strength and may require additional reinforcement such as welding or adhesives. Splice joints provide enhanced structural integrity and distribute stress more evenly across the connection, though they tend to be more complex to fabricate and require precise cutting and fitting. Choosing between butt and splice joints depends on factors like load requirements, material type, and fabrication capabilities.

Choosing the Right Joint for Your Project

Choosing between a butt joint and a splice joint depends on the strength and alignment requirements of your project. Butt joints are ideal for simple, perpendicular connections where ease of assembly and basic support are needed, while splice joints offer enhanced strength and continuity by joining two ends in a straight line, often used in structural applications. Evaluating load-bearing capacity, material type, and joint accessibility ensures optimal performance and durability for your woodworking or metalworking project.

Butt joint Infographic

libterm.com

libterm.com