Countersinking improves the fit and finish of fasteners by creating a conical hole that allows screw heads to sit flush with or below a surface. This technique is essential for applications requiring smooth surfaces and enhanced aesthetic appeal, as well as reducing stress concentrations around fasteners. Discover how countersinking can enhance your projects and learn best practices by reading the full article.

Table of Comparison

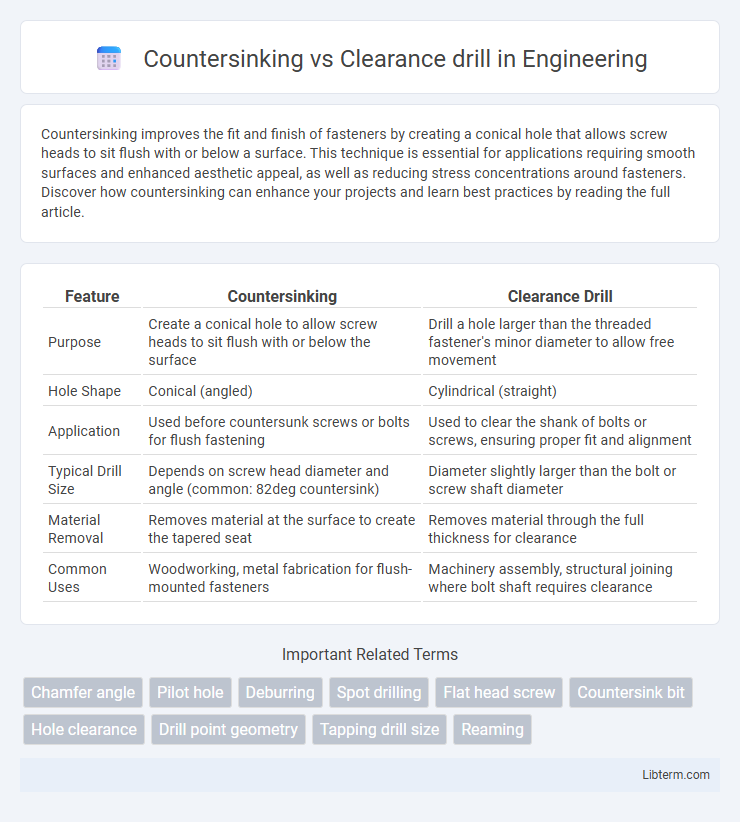

| Feature | Countersinking | Clearance Drill |

|---|---|---|

| Purpose | Create a conical hole to allow screw heads to sit flush with or below the surface | Drill a hole larger than the threaded fastener's minor diameter to allow free movement |

| Hole Shape | Conical (angled) | Cylindrical (straight) |

| Application | Used before countersunk screws or bolts for flush fastening | Used to clear the shank of bolts or screws, ensuring proper fit and alignment |

| Typical Drill Size | Depends on screw head diameter and angle (common: 82deg countersink) | Diameter slightly larger than the bolt or screw shaft diameter |

| Material Removal | Removes material at the surface to create the tapered seat | Removes material through the full thickness for clearance |

| Common Uses | Woodworking, metal fabrication for flush-mounted fasteners | Machinery assembly, structural joining where bolt shaft requires clearance |

Introduction to Countersinking and Clearance Drilling

Countersinking involves creating a conical hole that allows the screw head to sit flush with or below the surface, enhancing the appearance and preventing snagging. Clearance drilling, on the other hand, refers to drilling a hole slightly larger than the screw's diameter to allow free movement through the material, ensuring proper alignment and preventing thread damage. Both techniques are essential in assembly and fastening processes, with countersinking focusing on surface finish and clearance drilling prioritizing fit and functionality.

Definition of Countersinking

Countersinking is a machining process used to create a conical hole that allows the head of a countersunk screw or fastener to sit flush with or below the surface of the material. This technique ensures a smooth finish for aesthetic purposes and prevents snagging or interference in assemblies. Unlike clearance drilling, which simply creates a hole slightly larger than the screw diameter to allow passage, countersinking specifically shapes the hole to accommodate the screw head profile.

Definition of Clearance Drill

A clearance drill is a slightly larger hole drilled through a non-load-bearing material to allow a bolt, screw, or fastener to pass freely without engaging the material. This ensures that only the threaded portion of the fastener grips the load-bearing part, preventing binding or misalignment during assembly. Countersinking, by contrast, involves creating a conical recess for a flathead screw to sit flush with or below the surface.

Key Differences Between Countersinking and Clearance Drill

Countersinking creates a conical hole to allow fastener heads to sit flush with or below the surface, improving aesthetics and reducing snagging. Clearance drilling produces a straight hole slightly larger than the screw shaft diameter, enabling unobstructed passage of the fastener shank while allowing the threads to engage in the mating material. The key difference lies in countersinking shaping the hole for flush fastening, whereas clearance drilling ensures proper fit and alignment without altering the fastener head position.

Applications of Countersinking

Countersinking is primarily applied in woodworking and metalworking to create a conical hole that allows flathead screws or bolts to sit flush with or below the surface, enhancing aesthetic appeal and preventing snagging. It is commonly used in assembly processes requiring smooth finishes, such as cabinetry, furniture making, aerospace, and automotive industries. Countersinking also facilitates accurate alignment and improved load distribution in mechanical joins by ensuring proper screw seating.

Applications of Clearance Drilling

Clearance drilling is primarily used to create hole diameters larger than the fastener's shank, allowing bolts or screws to pass through without engaging the material. This technique is crucial in applications requiring precise alignment and free movement, such as assembling automotive components, machinery joints, and structural steel frameworks. By preventing thread damage and ensuring smooth assembly, clearance drilling enhances maintenance efficiency and extends the lifespan of mechanical connections.

Tools and Equipment for Countersinking

Countersinking tools include specialized countersink bits designed to create conical holes that allow screw heads to sit flush with or below the material surface. Common equipment consists of hand drills or drill presses fitted with high-speed steel or carbide countersink cutters, which provide durability and precision in various materials like wood, metal, and plastic. Using adjustable countersink wrenches or collars enhances control over the depth and angle, ensuring accurate, clean recesses that improve fastening quality and aesthetics.

Tools and Equipment for Clearance Drilling

Clearance drilling requires precise drill bits designed to create holes larger than the fastener shaft, ensuring smooth shaft passage without thread engagement. High-speed steel (HSS) and cobalt drill bits are commonly used for clearance holes due to their durability and heat resistance during metal drilling. Proper drill guides and depth stops enhance accuracy by preventing over-drilling and ensuring consistent hole size and placement.

Factors to Consider When Choosing Between Countersink and Clearance Drill

Choosing between countersinking and clearance drilling depends on the material thickness, screw type, and desired finish. Countersinking is ideal for flat head screws and provides a flush or recessed surface, improving aesthetics and preventing snagging, especially in thin materials. Clearance drilling allows for free screw rotation and proper fastening without deforming the material, suited for through holes and thicker substrates where precise alignment is critical.

Conclusion: Selecting the Right Drilling Technique

Selecting the right drilling technique depends on the specific requirements of the assembly, such as screw type, material thickness, and desired finish. Countersinking provides a flush surface by accommodating flat-head screws, ideal for aesthetic and functional applications. Clearance drilling creates a loose hole allowing the screw to pass freely, suitable for fastening separate components without threading the upper material.

Countersinking Infographic

libterm.com

libterm.com