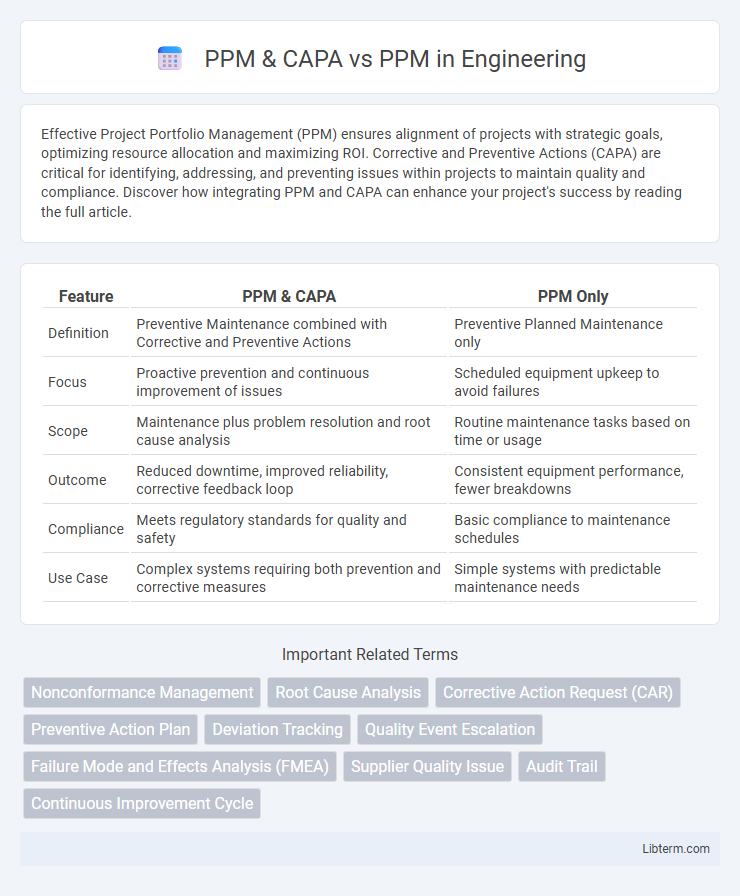

Effective Project Portfolio Management (PPM) ensures alignment of projects with strategic goals, optimizing resource allocation and maximizing ROI. Corrective and Preventive Actions (CAPA) are critical for identifying, addressing, and preventing issues within projects to maintain quality and compliance. Discover how integrating PPM and CAPA can enhance your project's success by reading the full article.

Table of Comparison

| Feature | PPM & CAPA | PPM Only |

|---|---|---|

| Definition | Preventive Maintenance combined with Corrective and Preventive Actions | Preventive Planned Maintenance only |

| Focus | Proactive prevention and continuous improvement of issues | Scheduled equipment upkeep to avoid failures |

| Scope | Maintenance plus problem resolution and root cause analysis | Routine maintenance tasks based on time or usage |

| Outcome | Reduced downtime, improved reliability, corrective feedback loop | Consistent equipment performance, fewer breakdowns |

| Compliance | Meets regulatory standards for quality and safety | Basic compliance to maintenance schedules |

| Use Case | Complex systems requiring both prevention and corrective measures | Simple systems with predictable maintenance needs |

Understanding PPM: An Overview

PPM (Parts Per Million) measures the frequency of defects in a manufacturing process, indicating the number of defective units per one million produced. CAPA (Corrective and Preventive Actions) addresses root causes of defects identified through PPM analysis to improve quality and prevent recurrence. Understanding PPM provides a quantitative baseline for quality control, while CAPA drives continuous process improvement based on that data.

What is CAPA? Key Concepts Explained

CAPA (Corrective and Preventive Action) is a vital quality management process aimed at identifying, addressing, and preventing defects or nonconformities in manufacturing and service industries. It focuses on root cause analysis to implement corrective actions for existing issues and preventive actions to avoid recurrence, ensuring continuous improvement and compliance with regulatory standards. By integrating CAPA with PPM (Parts Per Million), organizations enhance product quality metrics and reduce defect rates, driving operational excellence and customer satisfaction.

The Role of PPM in Quality Management

PPM (Parts Per Million) serves as a critical metric in quality management by quantifying the defect rate in manufacturing processes, enabling precise measurement of product quality and operational efficiency. CAPA (Corrective and Preventive Actions) complements PPM by addressing identified defects and implementing strategies to reduce future occurrences, enhancing overall quality control systems. Integrating PPM with CAPA ensures continuous quality improvement, minimizing defects and driving higher customer satisfaction through systematic problem-solving and prevention.

CAPA Process: Steps and Best Practices

The CAPA process involves identifying nonconformities, performing root cause analysis, implementing corrective and preventive actions, and verifying their effectiveness to ensure continuous improvement in quality management. Key best practices include thorough documentation, timely response, cross-functional team collaboration, and regular review to prevent recurrence of issues. Integrating CAPA with PPM (Planned Preventive Maintenance) enhances operational reliability by addressing root causes of failures rather than merely scheduling routine maintenance.

PPM & CAPA: How They Work Together

PPM (Planned Preventive Maintenance) and CAPA (Corrective and Preventive Actions) work together by combining routine maintenance schedules with proactive problem-solving strategies to minimize equipment failures and improve operational efficiency. PPM ensures regular inspections and maintenance tasks are completed to prevent breakdowns, while CAPA addresses identified issues by investigating root causes and implementing corrective measures. This integrated approach enhances reliability, reduces downtime, and supports continuous improvement in manufacturing and quality management systems.

PPM Alone vs. Integrated PPM & CAPA Systems

PPM alone focuses on scheduling and performing preventive maintenance tasks to reduce equipment downtime and extend asset lifespan, relying primarily on time-based or usage-based triggers. Integrated PPM and CAPA systems combine preventive maintenance with corrective and preventive action workflows, enabling real-time issue detection, root cause analysis, and continuous improvement within the maintenance lifecycle. This integration improves operational efficiency by automating defect tracking, ensuring regulatory compliance, and enhancing decision-making through data analytics across maintenance and quality management functions.

Benefits of Combining PPM and CAPA

Combining Project Portfolio Management (PPM) and Corrective and Preventive Actions (CAPA) enhances organizational efficiency by aligning project execution with quality improvement processes, ensuring timely identification and resolution of risks. This integration facilitates data-driven decision-making, reducing operational costs and increasing project success rates by proactively addressing compliance and performance issues. Leveraging combined PPM and CAPA frameworks drives continuous improvement and strategic alignment across all projects, ultimately maximizing resource utilization and stakeholder satisfaction.

Challenges in Implementing PPM & CAPA

Implementing PPM (Planned Preventive Maintenance) combined with CAPA (Corrective and Preventive Actions) presents challenges such as the complexity of integrating real-time data for accurate failure prediction and the difficulty in coordinating cross-functional teams to address root causes effectively. Ensuring compliance with industry standards like ISO 9001 while maintaining minimal downtime requires robust documentation and continuous monitoring systems. Resource allocation and employee training further complicate execution, impacting the seamless transition from problem identification to corrective resolution within the PPM & CAPA framework.

Case Study: PPM vs. PPM with CAPA

The case study comparing PPM versus PPM with CAPA demonstrates a significant reduction in process deviations and non-conformances when Corrective and Preventive Actions (CAPA) are integrated into Planned Preventive Maintenance (PPM). Incorporating CAPA enhances root cause analysis and continuous improvement, leading to improved equipment reliability and decreased downtime. Data from the study showed a 30% decrease in maintenance-related failures and a 25% increase in overall operational efficiency.

Future Trends in PPM & CAPA Integration

Future trends in PPM (Project Portfolio Management) and CAPA (Corrective and Preventive Action) integration emphasize enhanced automation and predictive analytics to streamline risk identification and resolution across projects. Leveraging AI-driven insights enables more proactive decision-making, improving compliance and operational efficiency in quality management. The convergence of real-time data monitoring with PPM systems facilitates continuous improvement cycles, fostering agile responses to emerging issues before they impact project outcomes.

PPM & CAPA Infographic

libterm.com

libterm.com