Crevice corrosion occurs in confined spaces where stagnant fluids concentrate aggressive agents, accelerating metal degradation. This localized attack often affects areas like gasket seals, lap joints, or under deposits, posing significant challenges to structural integrity. Discover more about preventing and managing crevice corrosion in the rest of this article.

Table of Comparison

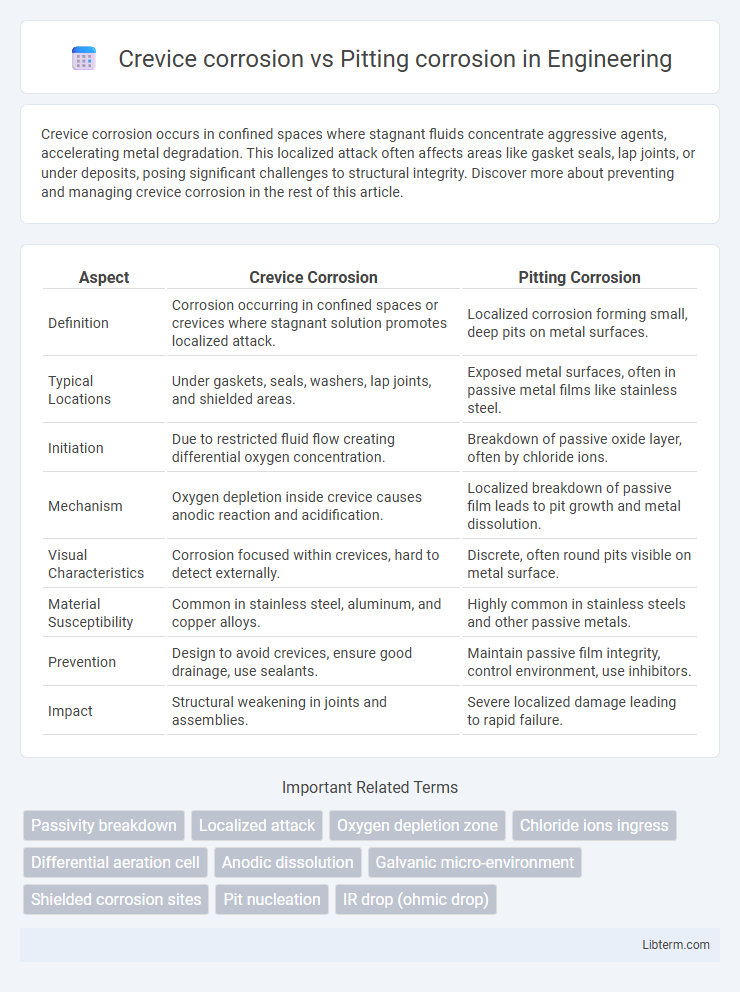

| Aspect | Crevice Corrosion | Pitting Corrosion |

|---|---|---|

| Definition | Corrosion occurring in confined spaces or crevices where stagnant solution promotes localized attack. | Localized corrosion forming small, deep pits on metal surfaces. |

| Typical Locations | Under gaskets, seals, washers, lap joints, and shielded areas. | Exposed metal surfaces, often in passive metal films like stainless steel. |

| Initiation | Due to restricted fluid flow creating differential oxygen concentration. | Breakdown of passive oxide layer, often by chloride ions. |

| Mechanism | Oxygen depletion inside crevice causes anodic reaction and acidification. | Localized breakdown of passive film leads to pit growth and metal dissolution. |

| Visual Characteristics | Corrosion focused within crevices, hard to detect externally. | Discrete, often round pits visible on metal surface. |

| Material Susceptibility | Common in stainless steel, aluminum, and copper alloys. | Highly common in stainless steels and other passive metals. |

| Prevention | Design to avoid crevices, ensure good drainage, use sealants. | Maintain passive film integrity, control environment, use inhibitors. |

| Impact | Structural weakening in joints and assemblies. | Severe localized damage leading to rapid failure. |

Understanding Crevice Corrosion

Crevice corrosion occurs in confined spaces where stagnant solution becomes trapped, creating a localized environment that accelerates metal degradation, unlike pitting corrosion which forms discrete holes on exposed surfaces. The restricted geometry in crevices causes oxygen depletion, leading to differential aeration and aggressive chloride ion concentration, driving the corrosion process. Recognizing crevice corrosion is essential for preventing structural failures in engineered joints, gaskets, and under deposits in marine and industrial applications.

What is Pitting Corrosion?

Pitting corrosion is a localized form of corrosion that results in the creation of small, deep cavities or pits on metal surfaces, primarily occurring in stainless steel and aluminum alloys. This type of corrosion is highly destructive due to its ability to penetrate protective oxide layers, leading to rapid metal degradation even in environments with low overall corrosion rates. Pitting corrosion typically initiates at sites where chloride ions concentrate, causing the breakdown of passive films and promoting aggressive metal attack.

Key Differences Between Crevice and Pitting Corrosion

Crevice corrosion occurs in confined spaces where stagnant solution allows localized attack, while pitting corrosion forms small, discrete pits on metal surfaces exposed to a corrosive environment. Crevice corrosion typically initiates in shielded areas such as gasket contacts or lap joints, whereas pitting arises from breakdown of passive oxide layers due to aggressive ions like chlorides. Both types result in localized damage, but crevice corrosion needs geometric constraints, and pitting can occur on open surfaces with direct electrolyte exposure.

Common Causes of Crevice Corrosion

Crevice corrosion commonly occurs in stagnant microenvironments where oxygen depletion inside crevices leads to aggressive localized attack, often caused by shielded areas under gaskets, deposits, or lap joints. The presence of chloride ions accelerates this process by lowering pH and increasing metal ion solubility within the crevice, promoting further corrosion. Unlike pitting corrosion, which initiates on exposed metal surfaces, crevice corrosion specifically requires confined spaces that restrict ion exchange and oxygen diffusion.

Primary Factors Leading to Pitting Corrosion

Pitting corrosion primarily occurs due to the localized breakdown of passive oxide films on metal surfaces, often triggered by chloride ions attacking specific sites. Factors such as oxygen concentration, the presence of aggressive ions (e.g., chlorides), and variations in metal composition significantly influence pitting initiation. In contrast, crevice corrosion develops in shielded areas where stagnant solution creates differential aeration cells, leading to a more enclosed corrosion mechanism.

Visual Identification: Crevice vs. Pitting Corrosion

Crevice corrosion appears as localized corrosion occurring within confined spaces such as gasket interfaces or under deposits, showing elongated or irregular corrosion patterns. Pitting corrosion manifests as small, round, and deep cavities on metal surfaces, often resembling pinholes or tiny pits. Visual identification hinges on crevice corrosion's tendency for linear or hidden corrosion zones, while pitting is characterized by isolated, well-defined pit formations.

Materials Susceptible to Crevice and Pitting Corrosion

Stainless steels, aluminum alloys, copper alloys, and titanium are highly susceptible to both crevice and pitting corrosion, particularly in chloride-rich environments. Crevice corrosion often occurs in areas with restricted fluid access such as gasket interfaces and under deposits, while pitting corrosion commonly initiates at localized defects or inclusions on metal surfaces. Materials with passive oxide films, like stainless steels, are vulnerable because localized breakdown of this film triggers both crevice and pitting corrosion processes.

Effects on Structural Integrity and Performance

Crevice corrosion induces localized attacks in shielded areas, leading to significant metal loss and reduced load-bearing capacity, which compromises the overall structural integrity of materials. Pitting corrosion causes small, deep cavities that penetrate metal surfaces, accelerating crack initiation and propagation, ultimately deteriorating mechanical performance. Both corrosion types undermine durability, but crevice corrosion typically results in broader structural weakening, while pitting corrosion leads to brittle failure points.

Prevention and Control Methods

Effective prevention and control of crevice and pitting corrosion involve selecting corrosion-resistant materials such as stainless steels with high molybdenum content and applying protective coatings like epoxy or polyurethane. Maintaining adequate design practices to eliminate crevices and ensure proper drainage reduces moisture entrapment, which is critical in minimizing localized corrosion risks. Regular inspection combined with cathodic protection methods and the use of corrosion inhibitors further enhances the durability of metal structures exposed to aggressive environments.

Industrial Applications and Case Studies

Crevice corrosion occurs in confined spaces such as gasket seals and flange joints in industrial equipment, leading to material degradation where oxygen depletion creates aggressive localized environments, while pitting corrosion forms small cavities on metal surfaces exposed to chloride-rich environments, frequently damaging pipelines and storage tanks. Case studies in petrochemical plants reveal crevice corrosion causing significant failures in heat exchangers due to stagnant solution entrapment, whereas pitting corrosion has been responsible for leaks in stainless steel storage vessels in marine industries. Both corrosion types necessitate specialized inspection techniques like ultrasonic testing and tailored corrosion inhibitors to mitigate industrial asset deterioration and ensure operational safety.

Crevice corrosion Infographic

libterm.com

libterm.com