A soldered joint ensures a reliable electrical connection by melting solder to fuse metal components together, optimizing both conductivity and mechanical strength. Proper technique and materials are crucial for preventing issues like cold joints or corrosion, which can compromise performance. Discover how to achieve perfect soldered joints and improve your electronic projects in the rest of this article.

Table of Comparison

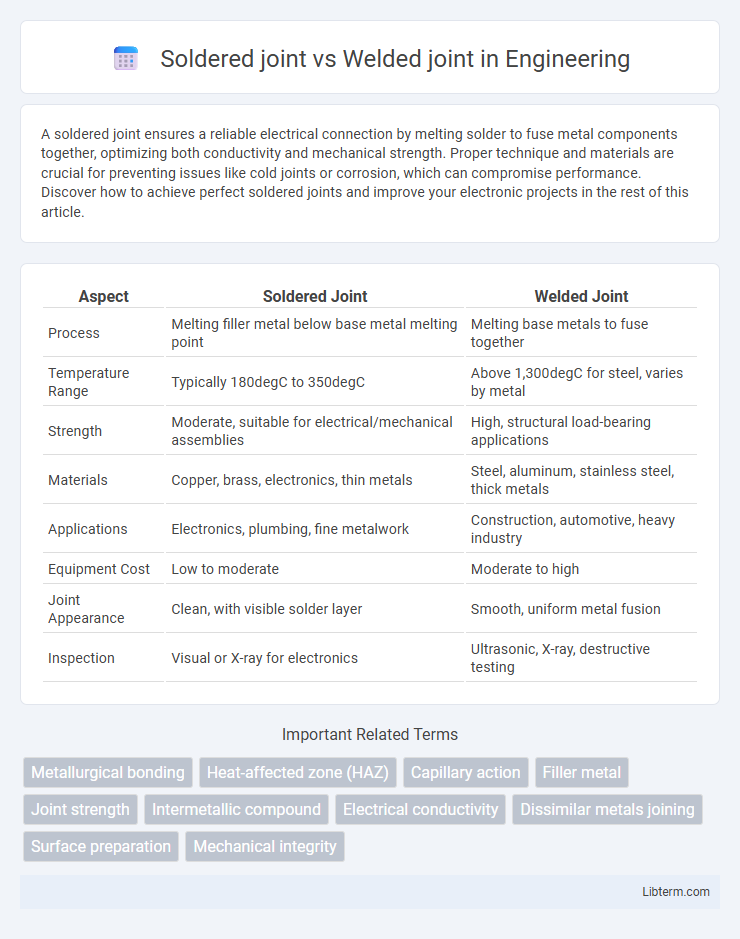

| Aspect | Soldered Joint | Welded Joint |

|---|---|---|

| Process | Melting filler metal below base metal melting point | Melting base metals to fuse together |

| Temperature Range | Typically 180degC to 350degC | Above 1,300degC for steel, varies by metal |

| Strength | Moderate, suitable for electrical/mechanical assemblies | High, structural load-bearing applications |

| Materials | Copper, brass, electronics, thin metals | Steel, aluminum, stainless steel, thick metals |

| Applications | Electronics, plumbing, fine metalwork | Construction, automotive, heavy industry |

| Equipment Cost | Low to moderate | Moderate to high |

| Joint Appearance | Clean, with visible solder layer | Smooth, uniform metal fusion |

| Inspection | Visual or X-ray for electronics | Ultrasonic, X-ray, destructive testing |

Introduction to Soldered and Welded Joints

Soldered joints involve joining metals by melting a filler metal with a lower melting point than the base metals, creating a bond without melting the workpieces. Welded joints fuse base metals together by heating them to their melting points, forming a strong, continuous bond upon cooling. Both techniques play crucial roles in electronics, plumbing, and structural applications, with optimizations based on strength, conductivity, and thermal resistance.

Definition and Basic Principles

Soldered joints involve joining metals using a filler metal with a melting point below 450degC, relying on capillary action to bond components without melting the base materials. Welded joints create a metallurgical fusion by melting the base metals and sometimes adding a filler material, resulting in a strong, continuous joint. The fundamental difference lies in soldering being a low-temperature process that does not melt the base metals, while welding requires high heat to fuse the metals together.

Materials Used in Soldering vs Welding

Soldered joints typically involve the use of filler materials such as tin-lead, lead-free alloys, or silver-based solder that melt at relatively low temperatures, allowing for delicate or heat-sensitive materials like copper, brass, and electronics components to be joined without damaging the base metals. Welding requires filler metals or base metals themselves to melt at much higher temperatures, using materials like steel, aluminum, or stainless steel fillers, which fuse the components together to create a strong, permanent bond suitable for heavy-duty applications. The choice of material in soldering versus welding directly affects joint strength, thermal stress tolerance, and electrical conductivity in the finished assembly.

Strength and Durability Comparison

Soldered joints typically exhibit lower strength and durability compared to welded joints due to the use of filler metals with lower melting points, making them suitable for electrical and delicate applications rather than structural loads. Welded joints create a metallurgical bond by melting the base metals, resulting in higher tensile strength and enhanced resistance to mechanical stress and fatigue. In environments requiring long-term durability under heavy loads or high temperatures, welded joints are preferred for their superior structural integrity and robustness.

Applications and Suitability

Soldered joints excel in electronics and delicate metal assemblies where heat-sensitive components require low-temperature bonding, offering excellent electrical conductivity and ease of repair. Welded joints suit heavy-duty structural applications such as automotive frames, pipelines, and construction steel, providing high mechanical strength and durability under dynamic loads. Choosing between soldering and welding depends on factors like material type, mechanical stress demands, thermal tolerance, and precision required for the application.

Process Temperatures and Techniques

Soldered joints typically use lower process temperatures ranging from 180degC to 250degC, utilizing a filler metal with a melting point below 450degC to bond components without melting the base metals. Welded joints require significantly higher temperatures, often above 1,000degC, to melt the base materials and create a strong metallurgical bond through techniques such as arc welding, MIG, or TIG. The choice between soldering and welding depends on thermal sensitivity of components and the required joint strength, with soldering favored for delicate electronics and welding suited for structural applications.

Joint Appearance and Finish

Soldered joints typically exhibit a smoother and shinier appearance with visible fillets where the solder has flowed, resulting in a clean and polished finish suitable for delicate electronics. Welded joints often present a more robust and textured surface with possible heat discoloration and slight unevenness caused by the fusion process, emphasizing strength over aesthetic refinement. The soldering process yields finer, more refined edges, while welding may require additional grinding or finishing to achieve a uniform look.

Cost and Equipment Requirements

Soldered joints typically require lower-cost equipment, such as soldering irons and basic solder wire, making them more economical for small-scale or delicate electronic assemblies. Welded joints demand more specialized and expensive machinery, including welding power supplies and gas or laser sources, resulting in higher initial investment costs suitable for robust metal fabrication. The cost difference between soldering and welding is significant, influencing the choice based on project scale, material thickness, and production volume.

Safety Considerations

Soldered joints typically operate at lower temperatures than welded joints, reducing the risk of thermal damage and making them safer for delicate electronic components. Welded joints, while stronger and more durable, require high heat and generate fumes, necessitating proper ventilation and protective equipment to prevent inhalation hazards and burns. Safety protocols for welding also include eye protection against intense UV radiation and fire prevention measures due to sparks and molten metal splatter.

Pros and Cons: Soldered vs Welded Joints

Soldered joints offer excellent electrical conductivity and are suitable for delicate electronic components, providing low thermal stress and ease of repair, but they have lower mechanical strength and limited heat resistance compared to welded joints. Welded joints provide superior mechanical strength, high durability, and better resistance to environmental factors, making them ideal for structural applications, yet they require higher temperatures, specialized equipment, and can cause thermal distortion. Choosing between soldered and welded joints depends on application requirements, balancing mechanical strength and thermal considerations against ease of assembly and component sensitivity.

Soldered joint Infographic

libterm.com

libterm.com