Precise chip control is essential for optimizing machining efficiency and surface quality, reducing tool wear and preventing workpiece damage during metalworking processes. Effective chip evacuation minimizes heat buildup, ensuring consistent cutting performance and prolonging tool life. Explore the rest of the article to discover advanced techniques and tools that enhance your chip control capabilities.

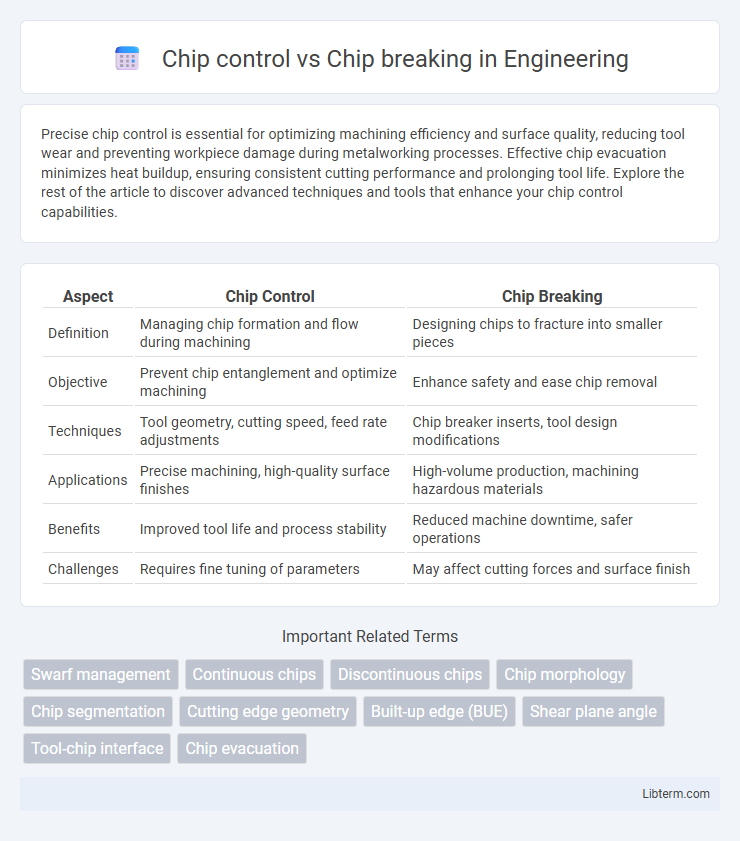

Table of Comparison

| Aspect | Chip Control | Chip Breaking |

|---|---|---|

| Definition | Managing chip formation and flow during machining | Designing chips to fracture into smaller pieces |

| Objective | Prevent chip entanglement and optimize machining | Enhance safety and ease chip removal |

| Techniques | Tool geometry, cutting speed, feed rate adjustments | Chip breaker inserts, tool design modifications |

| Applications | Precise machining, high-quality surface finishes | High-volume production, machining hazardous materials |

| Benefits | Improved tool life and process stability | Reduced machine downtime, safer operations |

| Challenges | Requires fine tuning of parameters | May affect cutting forces and surface finish |

Introduction to Chip Control and Chip Breaking

Chip control involves managing the shape and size of metal chips produced during machining to improve surface finish and tool life. Chip breaking refers to the intentional disruption of chips into smaller segments to prevent long, continuous chips that can damage both the workpiece and the cutting tool. Effective chip control and chip breaking are essential in optimizing machining processes by enhancing safety, reducing machine downtime, and maintaining product quality.

Importance of Proper Chip Management

Proper chip management in machining enhances tool life and ensures optimal surface finish by preventing chip recutting and damage. Effective chip control directs chips away from the cutting zone, reducing heat buildup and minimizing machine tool wear. Implementing chip breaking techniques further improves safety and operational efficiency by producing smaller, manageable chips that are easier to evacuate.

Defining Chip Control in Machining

Chip control in machining refers to techniques and tools used to manage the formation, shape, and evacuation of chips produced during cutting processes. Effective chip control enhances surface finish, prevents tool damage, and improves operational safety by ensuring chips are broken into manageable sizes. Methods for chip control include optimized tool geometry, chip breakers, coolant application, and adjusted cutting parameters tailored to specific materials and machine setups.

Understanding Chip Breaking Mechanisms

Effective chip control in machining is essential to prevent damage to tools and workpieces by managing chip shape and size through optimized cutting parameters and tool geometry. Understanding chip breaking mechanisms involves analyzing how material properties, cutting speed, feed rate, and tool rake angle influence chip fragmentation and evacuation. Advanced techniques such as segmented chip formation and dynamic chip breakers enhance machining efficiency by promoting controlled chip breakage and smoother chip flow.

Key Differences Between Chip Control and Chip Breaking

Chip control regulates the size and shape of metal chips during machining to ensure smooth removal and prevent tool damage. Chip breaking specifically focuses on fracturing chips into smaller, manageable pieces to avoid long, continuous chips that can entangle and disrupt the machining process. The key difference lies in chip control's broader role in managing chip formation characteristics, while chip breaking targets the physical disruption of chip continuity for enhanced safety and efficiency.

Factors Affecting Chip Formation

Chip control and chip breaking are influenced by factors such as cutting speed, feed rate, tool geometry, and material properties of both the workpiece and the tool. Higher cutting speeds and optimized rake angles promote smoother chip flow and effective chip fragmentation, reducing tool wear and improving surface finish. Material hardness and ductility also dictate chip morphology, with tougher materials requiring precise adjustments for efficient chip breaking and control.

Tools and Technologies for Effective Chip Control

Advanced cutting tools with optimized geometry, such as chip breakers and segmented inserts, play a crucial role in effective chip control by fragmenting chips into manageable sizes to prevent machine damage and improve surface finish. Technologies like high-frequency vibration and ultrasonic-assisted machining enhance chip breakage by applying controlled oscillations, reducing cutting forces and heat generation. Integration of real-time monitoring systems and adaptive control algorithms further optimizes chip formation by adjusting cutting parameters dynamically, ensuring consistent tool life and machining efficiency.

Common Challenges in Chip Breaking

Chip control and chip breaking are critical in machining to prevent tool damage and ensure surface finish quality. Common challenges in chip breaking include inconsistent chip size, which can cause tool clogging and increase machine downtime, and improper chip evacuation leading to poor heat dissipation and tool wear. Effective chip breaker design and optimized cutting parameters are essential to mitigate issues like built-up edge formation and maintain continuous machining efficiency.

Benefits of Optimized Chip Handling

Optimized chip control enhances machining efficiency by minimizing tool wear and reducing heat generation, leading to extended tool life and improved surface finish quality. Effective chip breaking prevents chip entanglement and machine damage, ensuring consistent cutting performance and safer operations. Together, precise chip handling maximizes productivity and lowers overall manufacturing costs by reducing downtime and maintenance.

Best Practices for Chip Control and Chip Breaking

Effective chip control and chip breaking are essential for maintaining machining efficiency and tool longevity, with best practices including optimizing cutting parameters such as feed rate and spindle speed to produce manageable chip sizes. Using appropriate tools with chip breakers and selecting suitable coolant methods enhance chip evacuation, reducing heat and preventing damage to the workpiece and tooling. Consistent monitoring and adjustment based on material type and cutting conditions ensure improved surface finish, reduced cycle times, and minimized machine downtime.

Chip control Infographic

libterm.com

libterm.com