Dead load refers to the permanent, static weight of a structure, including its walls, floors, roofs, and any fixed installations. Understanding dead load is crucial for ensuring the safety and stability of buildings by accurately calculating the forces that the structure must support. Explore the rest of the article to learn how dead load impacts construction design and safety considerations.

Table of Comparison

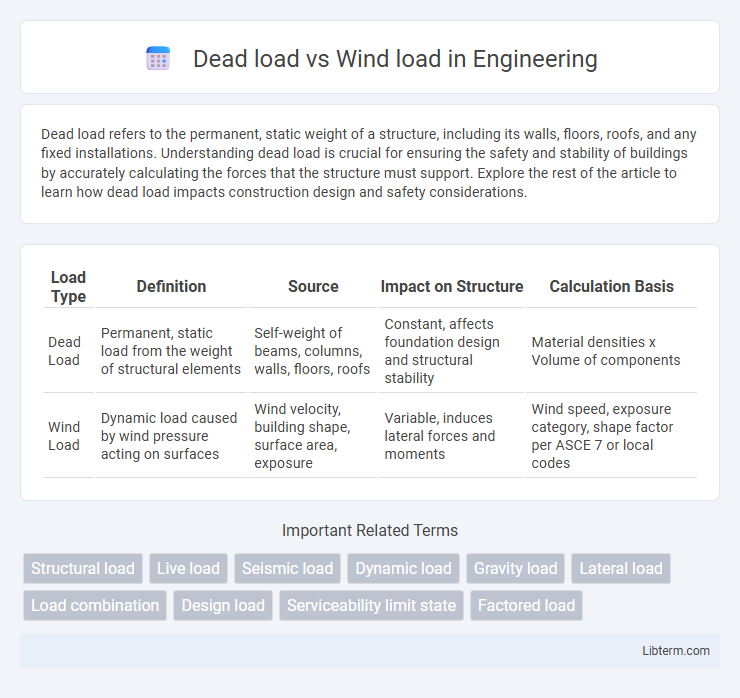

| Load Type | Definition | Source | Impact on Structure | Calculation Basis |

|---|---|---|---|---|

| Dead Load | Permanent, static load from the weight of structural elements | Self-weight of beams, columns, walls, floors, roofs | Constant, affects foundation design and structural stability | Material densities x Volume of components |

| Wind Load | Dynamic load caused by wind pressure acting on surfaces | Wind velocity, building shape, surface area, exposure | Variable, induces lateral forces and moments | Wind speed, exposure category, shape factor per ASCE 7 or local codes |

Introduction to Structural Loads

Structural loads are essential factors in engineering design, where dead loads refer to permanent, static forces from the weight of a building's materials like beams, walls, and floors. Wind loads represent dynamic forces exerted by wind pressure, varying based on geographic location, height, and exposure of the structure. Accurate calculation of dead and wind loads ensures stability, safety, and durability of buildings under different environmental conditions.

Defining Dead Load

Dead load refers to the permanent, static weight of a structure's components, including beams, floors, walls, and fixed equipment. It contrasts with wind load, which is a dynamic force exerted by wind pressure on the building's exterior surfaces. Accurately calculating dead load is essential for structural design to ensure stability and safety under combined loading conditions.

Understanding Wind Load

Wind load refers to the force exerted by air movement on a structure, influenced by factors such as wind speed, building shape, height, and geographic location. Unlike dead load, which is the constant weight of a structure and its fixed components, wind load is dynamic and varies with changing weather conditions. Proper calculation of wind load is crucial in structural engineering to ensure stability, prevent structural failure, and enhance safety during storms or high wind events.

Key Differences: Dead Load vs Wind Load

Dead load refers to the permanent, static weight of a structure's own materials, including beams, walls, and floors, while wind load is the dynamic force exerted by wind pressure on the exterior surfaces of a building. Dead loads are constant and predictable, typically measured in pounds per square foot (psf), whereas wind loads vary based on wind speed, direction, and building geometry, requiring complex calculations involving local wind codes. Unlike dead loads that contribute to structural stability, wind loads create lateral forces that demand specific design considerations for resisting bending and shear stresses.

Importance of Dead Load in Structural Design

Dead load represents the permanent static weight of a structure, including its walls, floors, roofs, and fixed equipment, making it a critical factor in ensuring structural stability and safety. Engineers prioritize dead load calculations to establish a reliable baseline for load-bearing capacity, which directly influences material selection and structural dimensions. Accurately accounting for dead loads minimizes risks of excessive deflection, settlement, or failure under both normal and extreme conditions.

Impact of Wind Load on Buildings

Wind load exerts lateral forces on buildings that can cause structural stress, sway, and potential failure if not properly accounted for in design. Engineers must consider wind speed, direction, and building shape to ensure stability and safety against dynamic pressure and uplift effects. Proper reinforcement and aerodynamic features are essential to mitigate wind-induced vibrations and prevent long-term damage to the building envelope.

Calculation Methods for Dead and Wind Loads

Dead load calculation involves determining the weight of permanent structural elements such as beams, columns, floors, and fixed equipment by multiplying their volume by material density. Wind load calculation is based on factors including wind speed, exposure category, building height, and shape, using standards like ASCE 7 or Eurocode EN 1991-1-4 to determine pressure coefficients and resultant forces. Accurate application of these calculation methods ensures structural safety and compliance with building codes.

Real-World Examples: Dead vs Wind Load

Dead load represents the permanent, static weight of a structure's components, such as beams, columns, and floors, that remain constant over time. Wind load varies dynamically, exerting lateral pressure on buildings during storms or high-wind events, influencing the design of facades and structural reinforcements. For example, skyscrapers in Chicago must account for substantial wind loads to prevent swaying, while residential homes primarily focus on dead loads for structural stability.

Building Codes and Load Considerations

Building codes rigorously define dead load as the permanent structural weight, including walls, floors, and fixed equipment, requiring precise calculation for structural stability. Wind load, governed by codes such as ASCE 7 and Eurocode EN 1991-1-4, varies with geographic location and building height, making accurate site-specific wind pressure analysis critical for design. Compliance with these codes ensures that both dead and wind loads are factored into structural calculations to prevent failure and enhance safety.

Best Practices for Load Optimization

Dead load and wind load require distinct strategies for load optimization to ensure structural integrity and cost-efficiency. Accurate assessment of dead loads involves precise calculation of permanent components like building materials and fixed equipment, while wind load optimization necessitates aerodynamic modeling and wind tunnel testing to mitigate lateral forces. Implementing advanced materials with high strength-to-weight ratios and adaptive structural designs enhances performance under varying load conditions, reducing overall stress and improving safety margins.

Dead load Infographic

libterm.com

libterm.com