Solution annealing enhances the mechanical properties of metals by heating them to a high temperature and rapidly cooling to achieve a uniform microstructure. This process dissolves alloying elements into a solid solution, improving corrosion resistance and strength. Discover how solution annealing can optimize your metal treatment in the rest of the article.

Table of Comparison

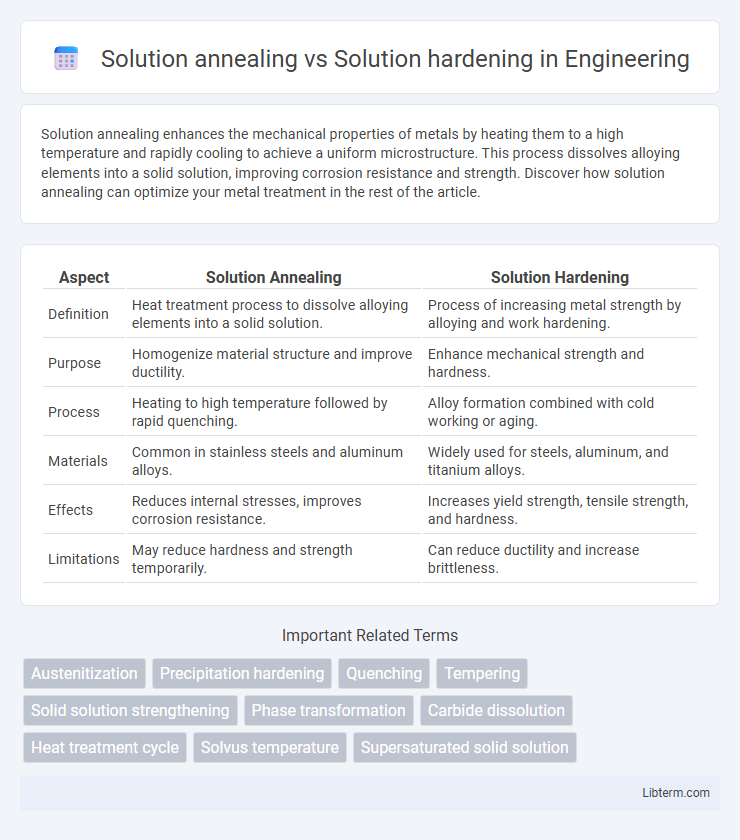

| Aspect | Solution Annealing | Solution Hardening |

|---|---|---|

| Definition | Heat treatment process to dissolve alloying elements into a solid solution. | Process of increasing metal strength by alloying and work hardening. |

| Purpose | Homogenize material structure and improve ductility. | Enhance mechanical strength and hardness. |

| Process | Heating to high temperature followed by rapid quenching. | Alloy formation combined with cold working or aging. |

| Materials | Common in stainless steels and aluminum alloys. | Widely used for steels, aluminum, and titanium alloys. |

| Effects | Reduces internal stresses, improves corrosion resistance. | Increases yield strength, tensile strength, and hardness. |

| Limitations | May reduce hardness and strength temporarily. | Can reduce ductility and increase brittleness. |

Introduction to Solution Annealing and Solution Hardening

Solution annealing involves heating a metal alloy to a high temperature to dissolve precipitates and homogenize the microstructure, improving ductility and corrosion resistance. Solution hardening, also known as solid solution strengthening, enhances the strength of an alloy by adding impurity atoms that distort the crystal lattice and impede dislocation movement. Both processes manipulate the alloy's microstructure but target different mechanical properties through controlled thermal or compositional modifications.

Definition and Principles of Solution Annealing

Solution annealing is a heat treatment process that involves heating an alloy to a specific temperature where its soluble elements dissolve into a single-phase solid solution, followed by rapid cooling to retain this homogeneous structure. This method eliminates precipitates and internal stresses, restoring ductility and improving corrosion resistance. Unlike solution hardening, which increases strength through the addition of solute atoms that create lattice distortions, solution annealing focuses on homogenizing the microstructure for enhanced mechanical properties.

Definition and Principles of Solution Hardening

Solution hardening, also known as solution strengthening, involves increasing a metal's strength by dissolving alloying elements into its crystal structure, creating a solid solution that impedes dislocation movement. This process relies on atomic size differences and the resulting lattice strain to enhance mechanical properties without forming second-phase particles. In contrast, solution annealing is a heat treatment designed to dissolve precipitates and homogenize the alloy, reversing the hardening effect while restoring ductility and reducing internal stresses.

Key Differences Between Solution Annealing and Hardening

Solution annealing involves heating a metal alloy to a high temperature to dissolve precipitates and achieve a homogeneous solid solution, followed by rapid cooling to retain the solution. Solution hardening, also known as solid solution strengthening, enhances metal strength by introducing impurity atoms into the crystal lattice, which distort the lattice and hinder dislocation movement. The key difference lies in annealing focusing on achieving uniformity and relieving stresses, while hardening specifically targets increasing material strength through atomic-level lattice distortions.

Metallurgical Processes Involved

Solution annealing involves heating an alloy to a temperature where the solute atoms dissolve into the solvent matrix, creating a single-phase solid solution, followed by rapid cooling to retain this homogeneous structure. Solution hardening relies on the presence of solute atoms in the metal lattice, which impede dislocation motion and increase strength without requiring a phase transformation. Both processes manipulate the microstructure through controlled heat treatment to optimize mechanical properties in metals such as stainless steels and aluminum alloys.

Material Applications and Suitability

Solution annealing is a heat treatment process primarily used for stainless steels and high-alloy materials to dissolve carbides and homogenize the microstructure, improving corrosion resistance and ductility. Solution hardening, often applied to aluminum and copper alloys, increases strength through atomic-level alloying without phase changes, making it ideal for lightweight structural components requiring high strength and moderate corrosion resistance. Selecting between solution annealing and solution hardening depends on the desired mechanical properties and environmental resistance needed for applications such as aerospace, chemical processing, or marine industries.

Effects on Microstructure and Mechanical Properties

Solution annealing dissolves alloying elements into a single-phase solid solution, resulting in a homogenized microstructure that reduces internal stresses and refines grain structure, enhancing ductility and toughness. Solution hardening, often achieved through rapid cooling or quenching, traps alloying elements in a supersaturated solid solution, creating lattice distortions that increase yield strength and hardness but may reduce ductility. The balance between these processes directly influences mechanical properties such as tensile strength, elongation, and impact resistance by controlling precipitate formation and dislocation movement within the microstructure.

Advantages and Limitations of Each Process

Solution annealing enhances ductility and corrosion resistance by dissolving alloying elements and homogenizing the microstructure but may reduce strength due to grain growth. Solution hardening increases strength and hardness through precipitation of particles within the metal matrix yet can lead to reduced toughness and increased brittleness. Selecting between solution annealing and solution hardening depends on the desired balance between mechanical properties and corrosion resistance for specific applications.

Industrial Examples and Case Studies

Solution annealing involves heating alloys such as stainless steel to dissolve precipitates, improving ductility and corrosion resistance, as demonstrated in shipbuilding industries where improved weldability is critical. In contrast, solution hardening, used in aerospace components like turbine blades, incorporates alloying elements to create a solid solution that enhances strength and wear resistance without significant heat treatment steps. Case studies on automotive engine parts reveal that solution annealing reduces stress corrosion cracking, while solution hardening improves fatigue life and hardness under high-stress conditions.

Conclusion: Choosing the Right Heat Treatment Technique

Solution annealing and solution hardening are distinct heat treatment techniques tailored for specific metallurgical needs, with solution annealing primarily aimed at dissolving precipitates to enhance ductility and corrosion resistance, while solution hardening focuses on increasing material strength through controlled precipitation. Selecting the appropriate method depends on the alloy composition and desired mechanical properties, balancing factors such as toughness, hardness, and resistance to stress corrosion cracking. Comprehensive evaluation of application requirements ensures optimal performance, making the choice between solution annealing and hardening critical in materials engineering.

Solution annealing Infographic

libterm.com

libterm.com