Tensile strength measures a material's ability to withstand pulling forces without breaking, crucial for engineering and construction applications. Understanding this property helps ensure the durability and safety of structures and products under stress. Explore the rest of the article to learn how tensile strength impacts your projects and material choices.

Table of Comparison

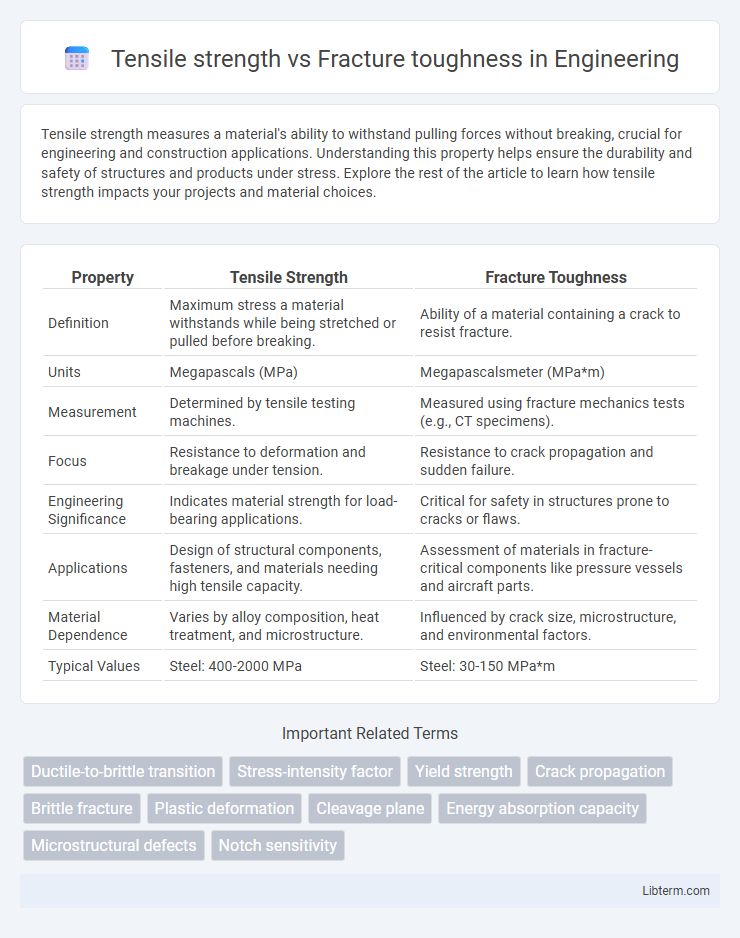

| Property | Tensile Strength | Fracture Toughness |

|---|---|---|

| Definition | Maximum stress a material withstands while being stretched or pulled before breaking. | Ability of a material containing a crack to resist fracture. |

| Units | Megapascals (MPa) | Megapascalsmeter (MPa*m) |

| Measurement | Determined by tensile testing machines. | Measured using fracture mechanics tests (e.g., CT specimens). |

| Focus | Resistance to deformation and breakage under tension. | Resistance to crack propagation and sudden failure. |

| Engineering Significance | Indicates material strength for load-bearing applications. | Critical for safety in structures prone to cracks or flaws. |

| Applications | Design of structural components, fasteners, and materials needing high tensile capacity. | Assessment of materials in fracture-critical components like pressure vessels and aircraft parts. |

| Material Dependence | Varies by alloy composition, heat treatment, and microstructure. | Influenced by crack size, microstructure, and environmental factors. |

| Typical Values | Steel: 400-2000 MPa | Steel: 30-150 MPa*m |

Introduction to Tensile Strength and Fracture Toughness

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking, reflecting its resistance to tension. Fracture toughness quantifies a material's ability to resist crack propagation and sudden failure under stress, indicating its resistance to fracture. Understanding both properties is essential for selecting materials in structural applications where both strength and durability under stress are critical.

Defining Tensile Strength

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking. It quantifies a material's resistance to failure under tension, critical for ensuring structural integrity in engineering applications. Fracture toughness, by contrast, evaluates a material's ability to resist crack propagation, highlighting its durability against structural fractures under stress.

Understanding Fracture Toughness

Fracture toughness measures a material's ability to resist crack propagation under stress, providing critical insight into its durability beyond tensile strength, which quantifies maximum stress a material can withstand while being stretched. This property is essential in applications involving cyclic loading or impact, as it predicts failure modes more accurately than tensile strength alone. Understanding fracture toughness involves analyzing parameters like the stress intensity factor (K_IC), critical crack size, and energy absorption before fracture, enabling engineers to design safer, more reliable components in aerospace, automotive, and construction industries.

Key Differences Between Tensile Strength and Fracture Toughness

Tensile strength measures the maximum stress a material can withstand under tension before failing, while fracture toughness quantifies a material's ability to resist crack propagation under stress. Tensile strength primarily evaluates the material's resistance to breaking under tension, whereas fracture toughness assesses resistance to crack initiation and growth, impacting durability and safety. These key differences influence material selection in engineering, where tensile strength suits load-bearing applications, and fracture toughness is critical for preventing catastrophic failure in flaw-prone structures.

Importance in Material Selection

Tensile strength measures a material's ability to withstand pulling forces without breaking, essential for applications requiring resistance to deformation and failure under load. Fracture toughness indicates a material's capacity to resist crack propagation, critical for ensuring durability and safety in structures subject to stress concentrations or impact. Selecting materials based on both tensile strength and fracture toughness ensures optimal performance by balancing load-bearing capacity with resistance to sudden fracture.

Measurement Methods and Testing Techniques

Tensile strength is primarily measured using standardized tensile tests such as ASTM E8, which involve applying uniaxial tension to a specimen until failure, providing data on maximum stress endured. Fracture toughness is evaluated through methods like the ASTM E399 standard, where pre-cracked specimens are subjected to controlled loading to determine resistance to crack propagation. Both testing techniques rely on precise specimen preparation and instrumentation, with tensile strength focusing on overall material strength, whereas fracture toughness emphasizes the material's ability to resist fracture under stress intensity factors.

Factors Affecting Tensile Strength and Fracture Toughness

Tensile strength is influenced by factors such as material composition, grain size, heat treatment, and processing methods, which determine the material's resistance to deformation under tension. Fracture toughness depends on microstructural features, crack size and shape, temperature, and loading rate, dictating a material's ability to resist crack propagation and catastrophic failure. Both properties are critical in material selection for engineering applications, balancing strength and durability under varying stress conditions.

Real-world Applications and Case Studies

Tensile strength measures a material's ability to withstand pulling forces without breaking, crucial for structural components like bridges and aircraft fuselages where load-bearing capacity is vital. Fracture toughness assesses a material's resistance to crack propagation, essential in high-risk applications such as aerospace engine parts and pressure vessels to prevent catastrophic failure. Case studies in aerospace engineering demonstrate materials with high fracture toughness outperform those with merely high tensile strength in preventing sudden fractures under stress.

Improving Material Performance: Enhancing Strength and Toughness

Tensile strength measures a material's ability to withstand pulling forces without breaking, critical for structural applications requiring high load-bearing capacity. Fracture toughness quantifies resistance to crack propagation, essential for preventing sudden failure in materials under stress. Improving material performance involves optimizing microstructure through alloying, heat treatment, and composite reinforcement to achieve a balance between high tensile strength and enhanced fracture toughness.

Conclusion: Choosing the Right Property for Your Application

Tensile strength measures a material's ability to withstand pulling forces without breaking, making it essential for applications requiring high load-bearing capacity. Fracture toughness evaluates a material's resistance to crack propagation and is crucial for components exposed to impact or stress concentrations. Selecting the right property depends on whether the application prioritizes load resistance or durability against crack growth and sudden failure.

Tensile strength Infographic

libterm.com

libterm.com