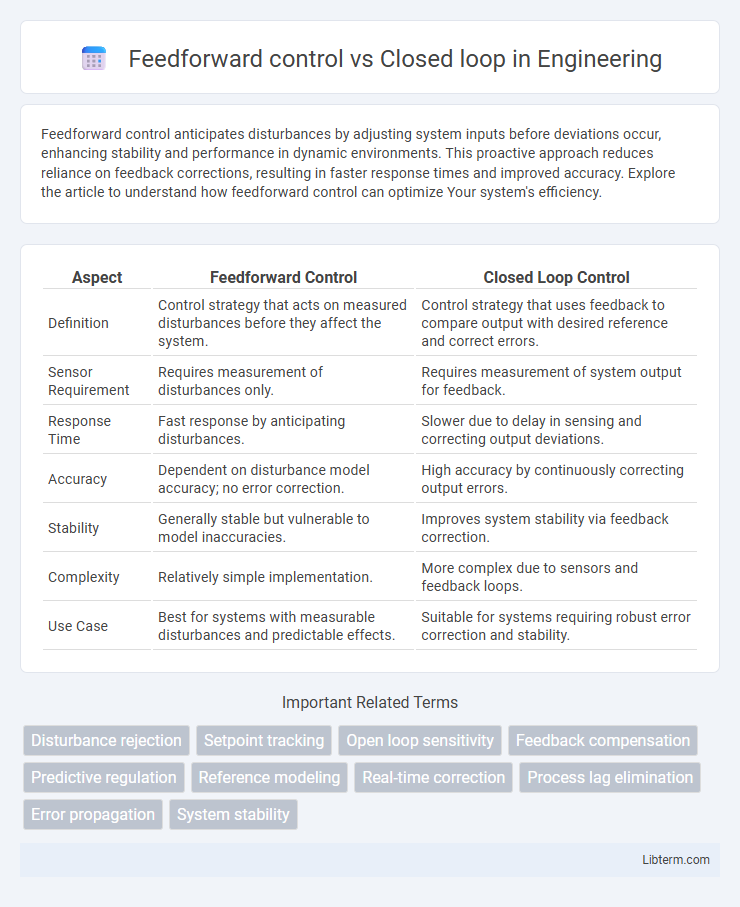

Feedforward control anticipates disturbances by adjusting system inputs before deviations occur, enhancing stability and performance in dynamic environments. This proactive approach reduces reliance on feedback corrections, resulting in faster response times and improved accuracy. Explore the article to understand how feedforward control can optimize Your system's efficiency.

Table of Comparison

| Aspect | Feedforward Control | Closed Loop Control |

|---|---|---|

| Definition | Control strategy that acts on measured disturbances before they affect the system. | Control strategy that uses feedback to compare output with desired reference and correct errors. |

| Sensor Requirement | Requires measurement of disturbances only. | Requires measurement of system output for feedback. |

| Response Time | Fast response by anticipating disturbances. | Slower due to delay in sensing and correcting output deviations. |

| Accuracy | Dependent on disturbance model accuracy; no error correction. | High accuracy by continuously correcting output errors. |

| Stability | Generally stable but vulnerable to model inaccuracies. | Improves system stability via feedback correction. |

| Complexity | Relatively simple implementation. | More complex due to sensors and feedback loops. |

| Use Case | Best for systems with measurable disturbances and predictable effects. | Suitable for systems requiring robust error correction and stability. |

Introduction to Feedforward and Closed Loop Control

Feedforward control predicts system disturbances and adjusts inputs proactively to maintain desired performance, improving response time and stability in dynamic environments. Closed loop control relies on feedback from system output to correct errors continuously, ensuring accuracy but often introducing lag due to measurement and processing delays. Combining both methods enhances precision by utilizing predictive adjustments and real-time corrections for optimal system regulation.

Key Concepts: Feedforward vs Closed Loop

Feedforward control anticipates disturbances and adjusts system inputs proactively based on model predictions, enhancing response speed and stability without relying on feedback. Closed loop control continuously monitors output variables using sensors to correct errors by comparing actual performance to desired setpoints, ensuring accuracy and robustness. Integrating feedforward with closed loop can optimize control systems by combining predictive adjustments with real-time error correction.

How Feedforward Control Works

Feedforward control anticipates disturbances by measuring input variables and applies corrective actions before errors occur, enhancing system stability and response time. It operates by using models or sensors to predict changes, allowing adjustments in the control input without waiting for the output feedback. This approach contrasts with closed loop control, which relies on feedback from the output to correct deviations after they happen.

How Closed Loop Control Operates

Closed loop control operates by continuously monitoring system output through feedback sensors, comparing the measured data to the desired setpoint to detect any deviations. The controller processes this feedback and adjusts the input in real-time to minimize error, ensuring stable and accurate performance despite disturbances. This dynamic feedback mechanism enables closed loop systems to self-correct, improve precision, and maintain desired operational conditions consistently.

Advantages of Feedforward Control Systems

Feedforward control systems offer the advantage of anticipating disturbances and adjusting processes proactively, which results in faster response times and improved system stability. Unlike closed loop control, feedforward control minimizes error before it occurs by utilizing real-time input measurements, enhancing accuracy in dynamic environments. This preemptive approach reduces the reliance on feedback signals, leading to less oscillation and more efficient control in applications such as temperature regulation and robotic motion.

Benefits of Closed Loop Control Mechanisms

Closed loop control mechanisms offer precise regulation by continuously monitoring output and adjusting inputs to maintain desired system performance under varying conditions. This adaptive feedback enhances system stability, reduces errors, and improves response to disturbances compared to feedforward control. Closed loop systems excel in environments with uncertainty or dynamic changes, ensuring reliability and accuracy in processes such as temperature regulation, motor control, and industrial automation.

Limitations: Feedforward vs Closed Loop

Feedforward control systems struggle with unmeasured disturbances and require an accurate model of the process, making them less effective if the system dynamics change or external factors are unpredictable. Closed loop control systems can compensate for disturbances through feedback, but they inherently respond slower due to the time delay in sensing and correcting errors. The primary limitation of feedforward control lies in its dependency on precise system modeling, while closed loop control is limited by potential stability issues and slower response times.

Practical Applications in Industry

Feedforward control is widely applied in chemical processing industries where system disturbances can be predicted and mitigated before affecting output, enhancing product consistency and reducing waste. Closed-loop control systems dominate manufacturing automation, such as CNC machining and robotic assembly, providing continuous feedback to maintain precision and adapt to real-time variations. Both control methods improve operational efficiency but feedforward excels in preemptive adjustments, while closed-loop ensures corrective actions based on actual performance data.

Choosing the Right Control Strategy

Choosing the right control strategy depends on system dynamics and disturbance predictability, with feedforward control excelling in anticipating changes by using measurable disturbances for proactive adjustments. Closed-loop control offers robustness by continuously monitoring output signals to correct errors and maintain desired performance despite unknown disturbances. Integrating feedforward with closed-loop systems often enhances overall control accuracy and stability in complex industrial processes.

Future Trends in Control System Design

Feedforward control enhances predictive accuracy by using real-time data and model-based adjustments to anticipate disturbances before they affect system performance, making it ideal for rapidly changing environments. Closed-loop control remains essential for correcting errors by continuously monitoring output and adjusting inputs, ensuring stability and reliability in systems with unpredictable variations. Future trends emphasize integrating machine learning with feedforward and closed-loop strategies to create adaptive, intelligent control systems that optimize performance and energy efficiency across diverse industrial applications.

Feedforward control Infographic

libterm.com

libterm.com