Gear pumps efficiently transfer fluids by using meshing gears to create a steady, pulseless flow ideal for hydraulic systems and lubrication. Their compact design ensures reliable performance under high pressure with minimal maintenance. Explore the rest of the article to understand how a gear pump can optimize Your fluid handling needs.

Table of Comparison

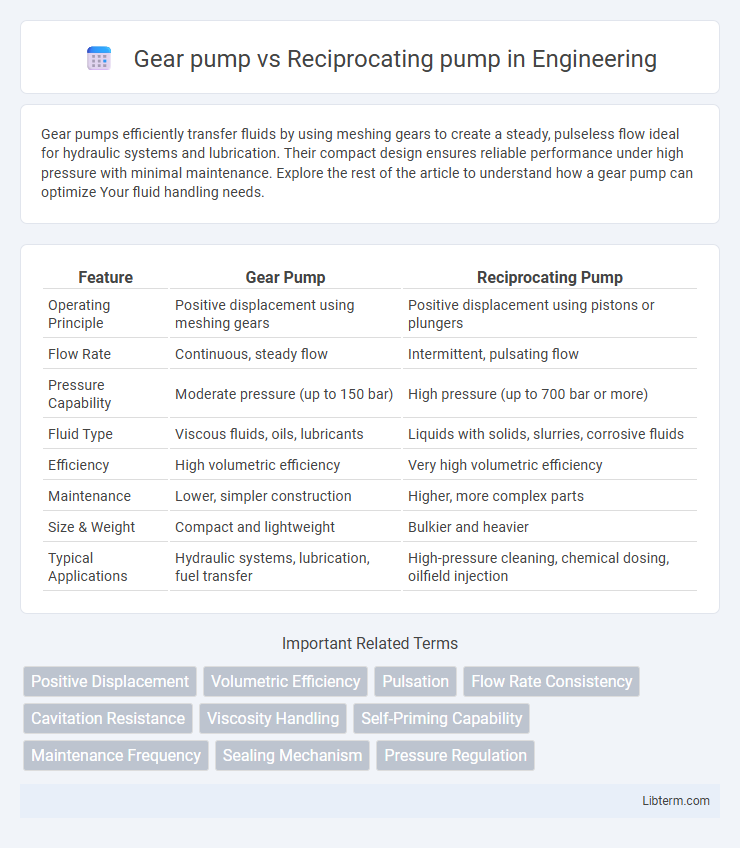

| Feature | Gear Pump | Reciprocating Pump |

|---|---|---|

| Operating Principle | Positive displacement using meshing gears | Positive displacement using pistons or plungers |

| Flow Rate | Continuous, steady flow | Intermittent, pulsating flow |

| Pressure Capability | Moderate pressure (up to 150 bar) | High pressure (up to 700 bar or more) |

| Fluid Type | Viscous fluids, oils, lubricants | Liquids with solids, slurries, corrosive fluids |

| Efficiency | High volumetric efficiency | Very high volumetric efficiency |

| Maintenance | Lower, simpler construction | Higher, more complex parts |

| Size & Weight | Compact and lightweight | Bulkier and heavier |

| Typical Applications | Hydraulic systems, lubrication, fuel transfer | High-pressure cleaning, chemical dosing, oilfield injection |

Introduction to Gear Pumps and Reciprocating Pumps

Gear pumps operate using meshing gears to transfer fluid, offering a smooth and consistent flow ideal for hydraulic applications. Reciprocating pumps utilize a piston or plunger in a cylinder to create suction and discharge, delivering high pressure and precise volume control for various industrial uses. Both pump types are essential in fluid handling, with gear pumps excelling in low-viscosity fluids and reciprocating pumps suited for high-pressure, precise dosing tasks.

Working Principle of Gear Pumps

Gear pumps operate on the principle of positive displacement, where two meshing gears rotate to transfer fluid by trapping it between the gear teeth and the pump casing. As the gears turn, fluid is carried from the pump's inlet to the outlet, creating a continuous flow with minimal pulsation. This mechanism provides high pressure and consistent volume output, making gear pumps ideal for hydraulic fluids and viscous liquids.

Working Principle of Reciprocating Pumps

Reciprocating pumps operate based on a positive displacement mechanism where a piston or plunger moves back and forth inside a cylinder, creating a vacuum that draws fluid in through an inlet valve and then forces it out through an outlet valve. This cyclical motion allows precise control over fluid flow and is ideal for high-pressure applications compared to gear pumps, which rely on rotating gears to transfer fluid. The working principle of reciprocating pumps ensures consistent delivery of fluids, making them suitable for tasks requiring accurate volume metering and high-pressure discharge.

Key Design Differences

Gear pumps feature rotating gears that trap fluid and create flow through continuous displacement, making them ideal for handling viscous fluids with steady pressure output. Reciprocating pumps use a piston or plunger that moves back and forth in a cylinder to create suction and discharge, enabling precise volume control and high-pressure generation. Key design differences include the gear pump's simpler rotational mechanism suited for smooth, low-pulsation flow versus the reciprocating pump's complex reciprocating motion designed for accurate, high-pressure fluid delivery.

Performance and Efficiency Comparison

Gear pumps deliver steady, high-pressure flow with minimal pulsation, making them efficient for consistent fluid transfer in hydraulic systems. Reciprocating pumps provide higher pressure capabilities and excellent volumetric efficiency, excelling in applications requiring precise flow control and handling viscous fluids. While gear pumps generally offer simpler design and lower maintenance, reciprocating pumps achieve superior efficiency in high-pressure scenarios due to their positive displacement mechanism.

Applications in Various Industries

Gear pumps excel in applications requiring consistent flow rates and high pressure, such as hydraulic systems, chemical processing, and lubrication in automotive industries. Reciprocating pumps are preferred for industries demanding precise dosing and high-pressure fluid transfer, including water treatment, oil and gas, and pharmaceutical manufacturing. Both pump types are integral to sectors like food and beverage, but gear pumps handle viscous fluids efficiently, while reciprocating pumps manage pulsatile flows with accuracy.

Advantages of Gear Pumps

Gear pumps offer high efficiency and consistent flow rates, making them ideal for hydraulic systems and industrial applications requiring smooth fluid delivery. Their compact design and fewer moving parts result in lower maintenance costs and increased reliability compared to reciprocating pumps. Gear pumps also excel in handling high-viscosity fluids and maintaining steady pressure under varying operating conditions.

Advantages of Reciprocating Pumps

Reciprocating pumps deliver high pressure and precise flow control, making them ideal for applications requiring accurate dosing or high-pressure fluid delivery. Their positive displacement mechanism ensures consistent volume output regardless of system pressure, enhancing efficiency in transferring viscous or corrosive liquids. Maintenance is simpler due to fewer moving parts exposed to fluid, resulting in increased reliability and longer service life compared to gear pumps in demanding industrial processes.

Limitations and Drawbacks

Gear pumps have limitations including low pressure handling, susceptibility to wear in abrasive fluids, and inability to handle fluids with high viscosity or solids. Reciprocating pumps face drawbacks such as pulsating flow leading to vibration, higher maintenance due to many moving parts, and limited flow rate capacity. Both pump types may experience reduced efficiency and operational issues under improper fluid conditions or excessive pressure demands.

Choosing the Right Pump for Your Needs

Selecting the right pump depends on application requirements such as flow rate, pressure, and fluid type. Gear pumps excel in delivering a steady, high-pressure flow with low pulsation, making them ideal for viscous fluids and lubrication systems. Reciprocating pumps provide precise flow control and high pressure for variable demand applications but require more maintenance due to their complex mechanical design.

Gear pump Infographic

libterm.com

libterm.com