Powder coating provides a durable, uniform finish that resists chipping, scratching, and fading, making it ideal for metal surfaces. This environmentally friendly process uses dry powder applied electrostatically and cured under heat to create a tough, protective layer. Explore the rest of the article to learn how powder coating can enhance your projects and extend the life of your products.

Table of Comparison

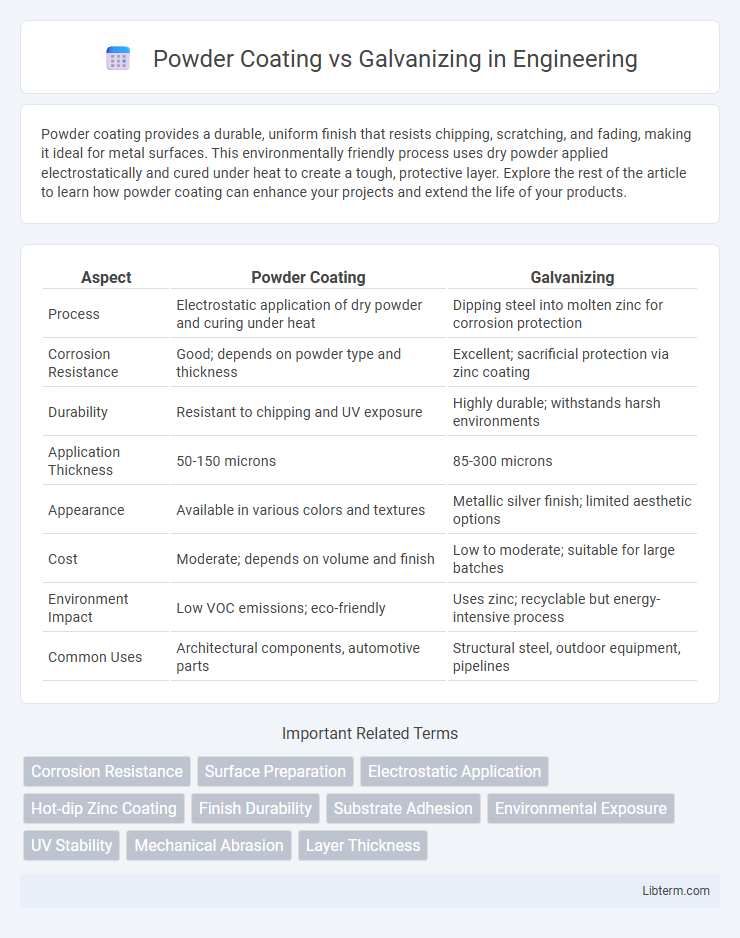

| Aspect | Powder Coating | Galvanizing |

|---|---|---|

| Process | Electrostatic application of dry powder and curing under heat | Dipping steel into molten zinc for corrosion protection |

| Corrosion Resistance | Good; depends on powder type and thickness | Excellent; sacrificial protection via zinc coating |

| Durability | Resistant to chipping and UV exposure | Highly durable; withstands harsh environments |

| Application Thickness | 50-150 microns | 85-300 microns |

| Appearance | Available in various colors and textures | Metallic silver finish; limited aesthetic options |

| Cost | Moderate; depends on volume and finish | Low to moderate; suitable for large batches |

| Environment Impact | Low VOC emissions; eco-friendly | Uses zinc; recyclable but energy-intensive process |

| Common Uses | Architectural components, automotive parts | Structural steel, outdoor equipment, pipelines |

Introduction to Surface Protection Methods

Powder coating and galvanizing are two key surface protection methods used to prevent corrosion and enhance durability in metal products. Powder coating provides a thick, uniform, and colorful finish through electrostatically applying dry powder and baking it for adhesion, offering excellent resistance to chipping and fading. Galvanizing involves coating steel or iron with a protective zinc layer through hot-dip or electro-galvanizing, ensuring sacrificial protection against rust in harsh environments.

What is Powder Coating?

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a metal surface, creating a durable, protective layer after curing under heat. This coating provides superior resistance to corrosion, UV rays, chipping, and scratching compared to traditional liquid paints. It is commonly used in automotive parts, appliances, and outdoor furniture due to its environmental benefits, such as low VOC emissions and minimal waste production.

What is Galvanizing?

Galvanizing is a corrosion protection process that involves applying a zinc coating to steel or iron to prevent rust and extend the metal's lifespan. This method provides a durable, long-lasting shield against environmental elements, making it ideal for outdoor structures and industrial applications. Compared to powder coating, galvanizing offers superior protection in harsh conditions by forming a metallurgical bond that resists chipping and abrasion.

Key Differences Between Powder Coating and Galvanizing

Powder coating involves applying a dry powder that is cured under heat to form a protective and decorative layer, primarily enhancing aesthetic appeal and corrosion resistance. Galvanizing is the process of coating steel or iron with a layer of zinc to provide robust, long-lasting corrosion protection, especially in harsh environments. The key differences lie in powder coating's emphasis on color variety and finish options versus galvanizing's superior durability and sacrificial protection against rust.

Durability and Longevity Comparison

Powder coating provides a thick, protective layer resistant to chipping, scratching, and fading, significantly enhancing surface durability in outdoor and industrial environments. Galvanizing offers superior corrosion resistance by forming a robust zinc coating that sacrificially protects steel from rust and environmental damage, extending metal lifespan up to 50 years or more in harsh conditions. Choosing between powder coating and galvanizing depends on the specific application requirements for wear resistance versus corrosion protection, with galvanizing generally delivering longer-lasting metal preservation.

Corrosion Resistance: Powder Coating vs Galvanizing

Powder coating provides a thick, uniform protective layer that resists corrosion by creating a hard, durable barrier against moisture, chemicals, and UV rays. Galvanizing involves coating steel with a layer of zinc, which offers cathodic protection by sacrificing itself to prevent rusting and extending the metal's lifespan even when the coating is scratched. While powder coating offers superior aesthetic options and chemical resistance, galvanizing excels in long-term corrosion protection for outdoor and industrial applications due to its self-healing properties.

Aesthetic Appeal and Finish Options

Powder coating offers a wide range of vibrant colors and smooth, customizable finishes that enhance aesthetic appeal and provide resistance to chipping and fading. Galvanizing typically results in a matte, silver-gray finish with industrial texture, offering durability but limited color options. Both methods protect metal surfaces, but powder coating excels in decorative versatility while galvanizing prioritizes corrosion resistance.

Environmental Impact and Sustainability

Powder coating reduces environmental pollution by emitting negligible volatile organic compounds (VOCs) and enabling efficient overspray reuse, making it a sustainable finishing option compared to traditional liquid paints. Galvanizing involves zinc coating that provides long-lasting corrosion resistance but relies on mining activities and energy-intensive processes that contribute to environmental degradation and greenhouse gas emissions. Both methods extend metal life cycles, reducing resource consumption and waste, yet powder coating generally offers a lower ecological footprint due to minimal emissions and resource efficiency.

Cost Comparison and Long-term Value

Powder coating typically incurs lower initial costs compared to galvanizing due to simpler application processes and less material usage. Galvanizing offers superior corrosion resistance, resulting in reduced maintenance expenses and longer asset lifespan, which can offset its higher upfront price over time. Evaluating total cost of ownership reveals that galvanizing provides greater long-term value for infrastructure exposed to harsh environments, while powder coating may be more cost-effective for indoor or less corrosive applications.

Choosing the Right Method for Your Project

Powder coating provides a durable, decorative finish ideal for indoor applications requiring vibrant colors and smooth surfaces, while galvanizing offers superior corrosion resistance suited for outdoor or industrial environments exposed to moisture and harsh conditions. Consider project requirements such as environmental exposure, desired aesthetics, and maintenance needs when choosing between powder coating and galvanizing. Cost efficiency and longevity also influence the decision, with galvanizing often favored for heavy-duty protection and powder coating preferred for customizable finishes.

Powder Coating Infographic

libterm.com

libterm.com