Tensile modulus measures a material's stiffness by quantifying its resistance to elastic deformation under tensile stress, playing a crucial role in engineering and material science. Understanding this property helps you select the right materials for applications requiring strength and flexibility balance. Explore the rest of the article to learn how tensile modulus impacts design and performance across various industries.

Table of Comparison

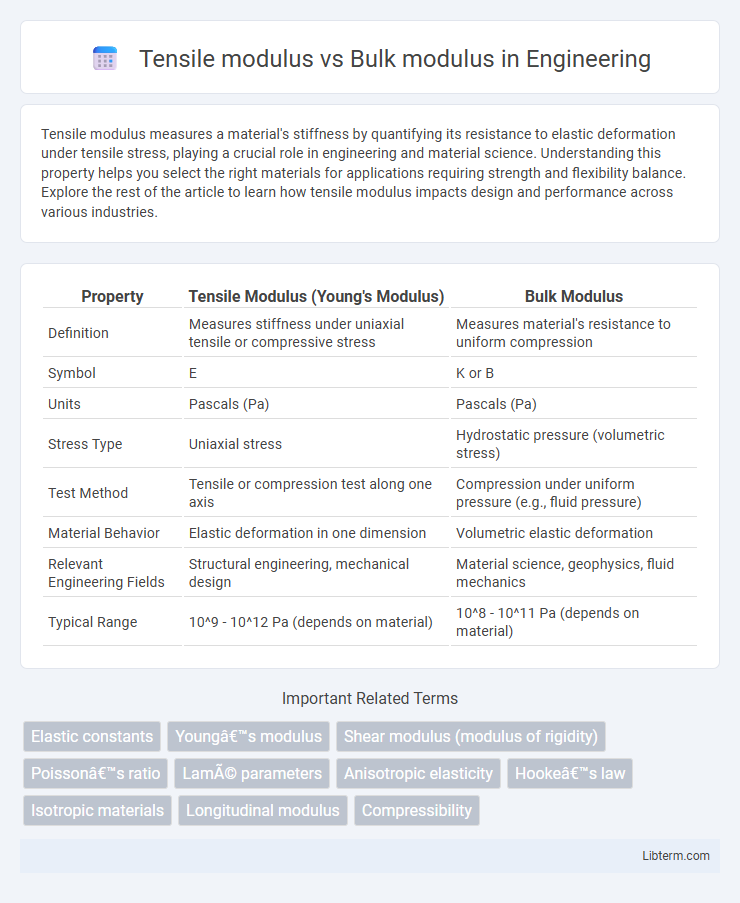

| Property | Tensile Modulus (Young's Modulus) | Bulk Modulus |

|---|---|---|

| Definition | Measures stiffness under uniaxial tensile or compressive stress | Measures material's resistance to uniform compression |

| Symbol | E | K or B |

| Units | Pascals (Pa) | Pascals (Pa) |

| Stress Type | Uniaxial stress | Hydrostatic pressure (volumetric stress) |

| Test Method | Tensile or compression test along one axis | Compression under uniform pressure (e.g., fluid pressure) |

| Material Behavior | Elastic deformation in one dimension | Volumetric elastic deformation |

| Relevant Engineering Fields | Structural engineering, mechanical design | Material science, geophysics, fluid mechanics |

| Typical Range | 10^9 - 10^12 Pa (depends on material) | 10^8 - 10^11 Pa (depends on material) |

Introduction to Modulus in Material Science

Tensile modulus, also called Young's modulus, measures a material's resistance to elongation under tensile stress, reflecting stiffness along one dimension. Bulk modulus quantifies a material's response to uniform pressure, indicating volumetric compressibility under compressive stress. Both moduli are fundamental mechanical properties used to characterize material deformation behavior in solid mechanics and materials engineering.

Defining Tensile Modulus

Tensile modulus, also known as Young's modulus, measures a material's resistance to uniaxial deformation under tensile stress, quantifying stiffness during stretching. It is defined as the ratio of tensile stress to tensile strain within the elastic limit, providing critical insight into the material's elastic properties. Bulk modulus, by contrast, evaluates the material's response to uniform pressure, reflecting incompressibility rather than directional stiffness.

Understanding Bulk Modulus

Bulk modulus quantifies a material's resistance to uniform compression, indicating how incompressible the substance is under pressure. It is defined as the ratio of applied pressure to the resulting volumetric strain, typically measured in pascals (Pa). Unlike tensile modulus, which measures stiffness during linear stretching, bulk modulus specifically characterizes volumetric elasticity and is crucial for understanding material behavior in high-pressure environments.

Key Differences Between Tensile and Bulk Modulus

Tensile modulus measures a material's resistance to deformation under uniaxial tensile stress, reflecting stiffness in stretching or pulling scenarios, while bulk modulus quantifies resistance to uniform compression, indicating how incompressible a material is under pressure. Tensile modulus is expressed in pascals (Pa) and is derived from stress-strain curves during tensile tests, whereas bulk modulus is calculated from changes in volume under hydrostatic pressure. The key difference lies in the nature of applied force--tensile modulus concerns linear elongation, whereas bulk modulus relates to volumetric compression.

Mathematical Expressions and Units

Tensile modulus, also known as Young's modulus (E), is mathematically expressed as \( E = \frac{\sigma}{\varepsilon} \), where \( \sigma \) represents tensile stress and \( \varepsilon \) is the corresponding tensile strain, measured in pascals (Pa). Bulk modulus (K) is defined as \( K = -V \frac{dP}{dV} \) or equivalently \( K = \frac{\Delta P}{\frac{\Delta V}{V}} \), quantifying a material's resistance to uniform compression with units in pascals (Pa) as well. Both moduli describe elastic properties but differ in deformation mode: tensile modulus applies to linear strain with unitless strain, while bulk modulus relates to volumetric strain involving pressure change per relative volume change.

Physical Significance and Applications

Tensile modulus quantifies a material's resistance to linear deformation under tensile stress, reflecting stiffness and elasticity in applications like structural beams and aerospace components. Bulk modulus measures a material's resistance to uniform compression, crucial for understanding volume changes in fluids, metals under high pressure, and geophysical studies. Both moduli provide essential mechanical property data for designing materials subjected to different stress states in engineering and materials science.

Factors Affecting Tensile and Bulk Moduli

Tensile modulus and bulk modulus are influenced by material composition, temperature, and microstructural factors such as grain size and phase distribution. Increasing temperature generally decreases both moduli due to enhanced atomic vibrations reducing stiffness, while alloying elements and composite reinforcements can increase tensile and bulk moduli by improving bonding strength and resistance to deformation. Crystalline materials exhibit higher moduli than amorphous materials because of their ordered atomic arrangements, which provide greater resistance to tensile stretching and volumetric compression.

Measurement Techniques for Both Moduli

Tensile modulus is typically measured using uniaxial tensile testing, where a specimen is stretched, and the stress-strain response is recorded to calculate the modulus from the linear elastic region. Bulk modulus measurement often involves hydrostatic compression tests, applying uniform pressure to a specimen and measuring the volumetric strain to determine resistance to uniform compression. Both techniques require precise instrumentation such as extensometers for tensile tests and pressure vessels with volumetric strain gauges for bulk modulus evaluations to ensure accurate and repeatable data.

Real-World Examples: Comparison Across Materials

The tensile modulus of steel, typically around 200 GPa, highlights its stiffness in stretching applications such as bridge cables and automotive parts, while its bulk modulus, approximately 160 GPa, reflects resistance to uniform compression in structural components. In contrast, rubber exhibits a low tensile modulus near 0.01 GPa, allowing significant elongation in products like tires and seals, whereas its bulk modulus, around 0.02 GPa, governs volume change under pressure. Materials like glass possess high bulk modulus values, close to 35 GPa, making them resistant to compression in windows and lenses, yet their tensile modulus, roughly 70 GPa, demonstrates brittleness under tensile stress.

Conclusion: Choosing the Right Modulus for Analysis

Tensile modulus measures a material's resistance to elongation under tension, making it ideal for analyzing structural elements subjected to stretching forces. Bulk modulus quantifies incompressibility and is better suited for applications involving uniform pressure or volumetric changes, such as fluid dynamics or geotechnical assessments. Selecting the appropriate modulus depends on whether the primary stress state involves axial deformation or volumetric compression to ensure accurate material behavior predictions.

Tensile modulus Infographic

libterm.com

libterm.com