Ductility measures a material's ability to deform under tensile stress without fracturing, indicating its flexibility and toughness. High ductility allows metals to be stretched into wires or molded into various shapes while maintaining structural integrity. Explore the rest of the article to understand how ductility impacts material selection and engineering applications for your projects.

Table of Comparison

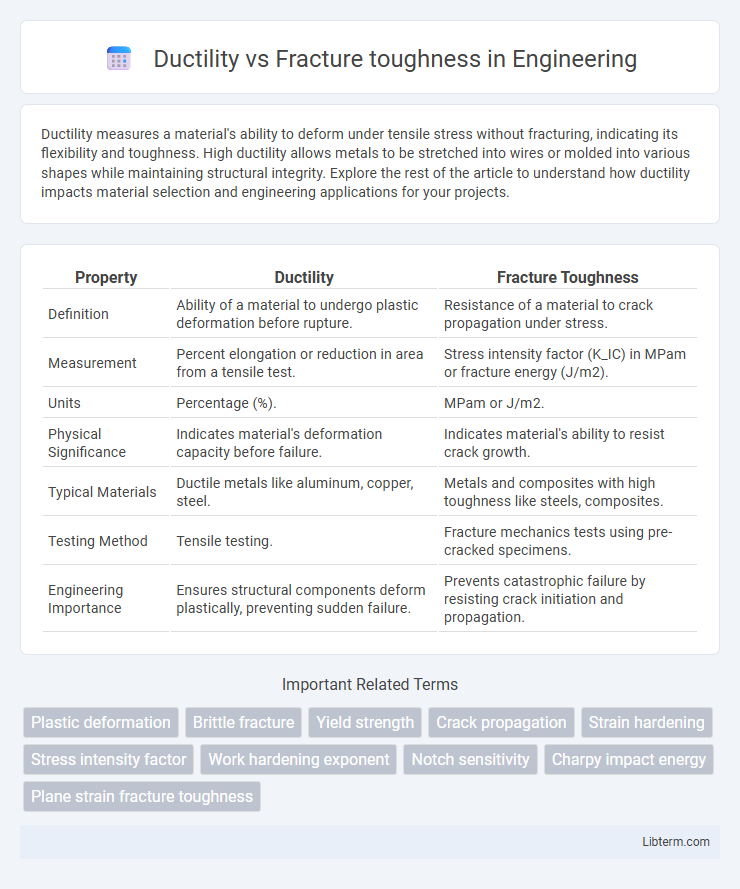

| Property | Ductility | Fracture Toughness |

|---|---|---|

| Definition | Ability of a material to undergo plastic deformation before rupture. | Resistance of a material to crack propagation under stress. |

| Measurement | Percent elongation or reduction in area from a tensile test. | Stress intensity factor (K_IC) in MPam or fracture energy (J/m2). |

| Units | Percentage (%). | MPam or J/m2. |

| Physical Significance | Indicates material's deformation capacity before failure. | Indicates material's ability to resist crack growth. |

| Typical Materials | Ductile metals like aluminum, copper, steel. | Metals and composites with high toughness like steels, composites. |

| Testing Method | Tensile testing. | Fracture mechanics tests using pre-cracked specimens. |

| Engineering Importance | Ensures structural components deform plastically, preventing sudden failure. | Prevents catastrophic failure by resisting crack initiation and propagation. |

Understanding Ductility: Definition and Importance

Ductility refers to a material's ability to undergo significant plastic deformation before fracture, making it crucial for applications requiring flexibility and resistance to sudden failure. It is measured by parameters such as elongation and reduction in area during tensile testing, indicating how much a material can stretch without breaking. Understanding ductility helps engineers select materials that absorb energy and deform under stress, preventing brittle fractures and enhancing structural safety.

What is Fracture Toughness? Key Concepts

Fracture toughness quantifies a material's ability to resist crack propagation under stress, serving as a critical parameter in assessing structural integrity. It is measured using standardized tests like the ASTM E399, which determine the stress intensity factor at which a crack grows. Unlike ductility, which describes a material's ability to deform plastically, fracture toughness specifically measures resistance to crack initiation and expansion, providing vital insights for failure prevention in engineering components.

Mechanisms Behind Ductility in Materials

Ductility in materials primarily arises from mechanisms such as dislocation motion and slip, which allow plastic deformation without immediate failure. The ability of materials to absorb energy through dislocation glide and twinning delays fracture, enhancing toughness in ductile metals like aluminum and copper. Fracture toughness, while related, measures resistance to crack propagation, with ductile materials typically exhibiting higher fracture toughness due to their capacity for plastic deformation.

Factors Affecting Fracture Toughness

Fracture toughness is significantly influenced by material microstructure, temperature, and loading rate, which determine a material's resistance to crack propagation. Higher ductility generally enhances fracture toughness by allowing plastic deformation near crack tips, absorbing energy and delaying fracture. Grain size, presence of impurities, and stress state also play critical roles, with finer grains and reduced residual stresses improving fracture toughness.

Ductility vs Fracture Toughness: Core Differences

Ductility measures a material's ability to undergo significant plastic deformation before rupture, primarily quantified by elongation or reduction in area during tensile testing. Fracture toughness quantifies a material's resistance to crack propagation, represented by critical stress intensity factors such as K_IC. While ductility reflects the extent of plastic deformation, fracture toughness focuses on the energy absorption capacity to prevent catastrophic fracture under stress concentration.

Testing Methods for Ductility and Fracture Toughness

Testing methods for ductility commonly include tensile tests and bend tests that measure the extent of plastic deformation before material failure, providing data on elongation and reduction in area. Fracture toughness is evaluated using standardized techniques like the Compact Tension (CT) test and Single Edge Notch Bend (SENB) test, quantifying a material's resistance to crack propagation under stress. Both testing methods rely on precise specimen preparation and load application to ensure accurate assessment of mechanical properties critical to engineering design and failure analysis.

Material Selection: Balancing Ductility and Fracture Toughness

Material selection for engineering applications requires balancing ductility and fracture toughness to ensure both deformability and resistance to crack propagation under stress. High ductility materials like aluminum alloys offer excellent formability but may lack the fracture toughness needed for impact-critical components, whereas materials such as certain steels provide superior fracture toughness at the expense of reduced ductility. Optimizing the material choice involves detailed analysis of service conditions, loading types, and failure modes to achieve structures that combine sufficient energy absorption with crack resistance.

Real-World Applications and Case Studies

Ductility, a material's ability to deform plastically before fracturing, is critical in applications like automotive crash components where energy absorption prevents catastrophic failure. Fracture toughness measures a material's resistance to crack propagation, essential in aerospace engineering to ensure structural integrity under stress and avoid sudden fractures. Case studies in bridge construction highlight the balance between ductility and fracture toughness to maintain safety and longevity under dynamic loads and environmental factors.

Enhancing Ductility and Fracture Toughness in Alloys

Enhancing ductility and fracture toughness in alloys involves precise control of microstructure through techniques like grain refinement, phase distribution optimization, and alloying element selection to achieve a balanced combination of strength and plastic deformation capacity. Incorporation of elements such as nickel, manganese, and silicon improves toughness by stabilizing microstructures and promoting energy absorption during crack propagation. Advanced processing methods, including thermomechanical treatments and controlled cooling rates, refine grain boundaries and eliminate defects, resulting in improved resistance to brittle fracture and increased ductility.

Future Trends in Materials Science: Improving Both Properties

Future trends in materials science focus on developing advanced composites and nanostructured alloys that simultaneously enhance ductility and fracture toughness. Emerging techniques such as additive manufacturing and molecular design enable precise control over microstructures, promoting energy absorption and crack resistance. Research increasingly explores multi-scale modeling and bio-inspired materials to achieve an optimal balance between flexibility and strength.

Ductility Infographic

libterm.com

libterm.com