Linear control systems regulate processes by applying feedback principles to maintain desired output levels through proportional, integral, and derivative actions. These systems are extensively used in engineering due to their simplicity, predictability, and ease of analysis using linear differential equations. Explore the rest of this article to understand how linear control can optimize your system's performance effectively.

Table of Comparison

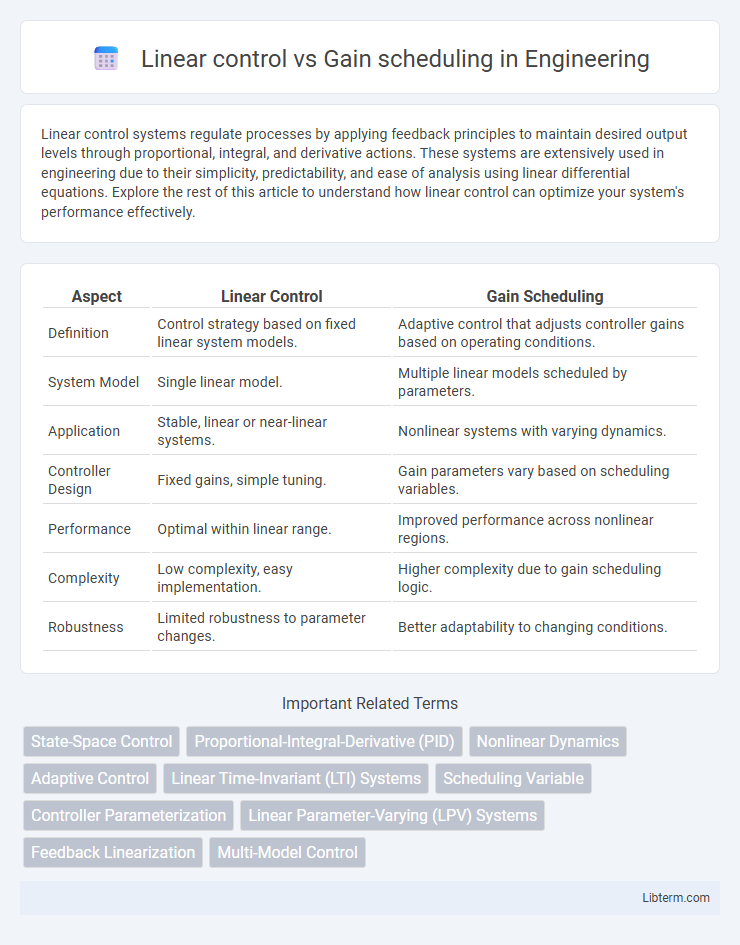

| Aspect | Linear Control | Gain Scheduling |

|---|---|---|

| Definition | Control strategy based on fixed linear system models. | Adaptive control that adjusts controller gains based on operating conditions. |

| System Model | Single linear model. | Multiple linear models scheduled by parameters. |

| Application | Stable, linear or near-linear systems. | Nonlinear systems with varying dynamics. |

| Controller Design | Fixed gains, simple tuning. | Gain parameters vary based on scheduling variables. |

| Performance | Optimal within linear range. | Improved performance across nonlinear regions. |

| Complexity | Low complexity, easy implementation. | Higher complexity due to gain scheduling logic. |

| Robustness | Limited robustness to parameter changes. | Better adaptability to changing conditions. |

Overview of Linear Control Systems

Linear control systems operate based on fixed linear approximations of system dynamics, relying on constant parameters to maintain stability and performance. These systems use proportional-integral-derivative (PID) controllers or state-space methods to regulate outputs in response to input changes within predictable linear operating regions. Compared to gain scheduling, which adjusts controller parameters dynamically for varying operating conditions, linear control remains simpler but often less effective for systems with nonlinearities or wide-range operational variations.

Principles of Gain Scheduling

Gain scheduling adapts controller parameters based on measurable operating conditions, ensuring robust performance across a wide range of system dynamics that linear control alone cannot handle effectively. By mapping the system's nonlinear behavior to multiple linear models, gain scheduling enables smooth transitions between controllers corresponding to different operating points. This principle leverages precomputed gains stored as functions of scheduling variables, optimizing control accuracy and stability in varying environments.

Key Differences Between Linear Control and Gain Scheduling

Linear control relies on fixed controller parameters designed for a specific operating point, ensuring stable performance within a limited range of conditions. Gain scheduling adapts controller gains dynamically based on measurable variables or operating points, allowing effective handling of nonlinearities and varying system dynamics. The key difference lies in linear control's static approach versus gain scheduling's real-time parameter adjustment to maintain optimal control across a broader operational envelope.

Advantages of Linear Control

Linear control offers simplicity and robustness by relying on well-established mathematical models and straightforward implementation techniques. It provides reliable performance in systems with consistent dynamics, ensuring predictable and stable responses under fixed operating conditions. The design process benefits from extensive theoretical tools, such as root locus and frequency response methods, facilitating ease of analysis and tuning.

Benefits of Gain Scheduling

Gain scheduling enables effective control of nonlinear systems by adjusting controller parameters based on operating conditions, improving system performance across varying regimes. This method extends the applicability of linear control techniques to complex systems with time-varying dynamics, ensuring stability and robustness. Gain scheduling also enhances adaptability, allowing controllers to maintain optimal performance during transient and steady-state conditions.

Typical Applications of Linear Control

Linear control is commonly applied in systems with stable, time-invariant dynamics such as temperature regulation, motor speed control, and aerospace flight control where precise and predictable responses are essential. Typical applications include industrial automation processes, servo mechanisms, and power system stabilization, benefiting from its simplicity and well-established design methods like PID control. This approach excels in environments where system parameters remain constant or vary insignificantly, ensuring reliable performance and ease of implementation.

Use Cases for Gain Scheduling

Gain scheduling is highly effective in controlling nonlinear systems with dynamics that vary significantly across different operating points, such as gas turbines, aircraft flight control, and chemical reactors. It adapts controller parameters in real-time based on measurable variables like speed, temperature, or altitude, ensuring stability and performance across a wide operating range. This approach outperforms fixed linear control in applications where system behavior cannot be accurately approximated by a single linear model.

Implementation Challenges

Linear control systems face challenges in handling nonlinear plant dynamics, leading to performance degradation outside a specific operating point. Gain scheduling addresses this by varying controller parameters according to measured variables, but implementation requires accurate system modeling and real-time parameter adjustment. Ensuring smooth transitions between different gain schedules often demands complex interpolation techniques and robust fault detection to prevent instability.

Performance Comparison: Linear Control vs Gain Scheduling

Linear control offers consistent performance for systems operating near a fixed operating point but can degrade significantly under varying conditions. Gain scheduling adjusts controller parameters based on real-time system states, enabling improved performance across a wider operating range and better handling of nonlinearities. Comparative studies demonstrate that gain scheduling achieves enhanced stability margins and faster response times in highly dynamic or nonlinear systems compared to conventional linear control methods.

Choosing the Right Approach for Your System

Choosing between linear control and gain scheduling depends on the system's operating range and nonlinearity. Linear control suits systems with stable dynamics around a fixed operating point, providing simplicity and robustness. Gain scheduling effectively handles varying conditions by adjusting controller parameters dynamically, making it ideal for nonlinear or time-varying systems requiring precise performance across a broad range.

Linear control Infographic

libterm.com

libterm.com