Transitional flow ensures smooth and logical movement between ideas, enhancing the clarity and coherence of your writing. Mastering this technique guides readers effortlessly from one point to the next, maintaining engagement and comprehension. Discover effective strategies to improve your transitional flow by reading the rest of this article.

Table of Comparison

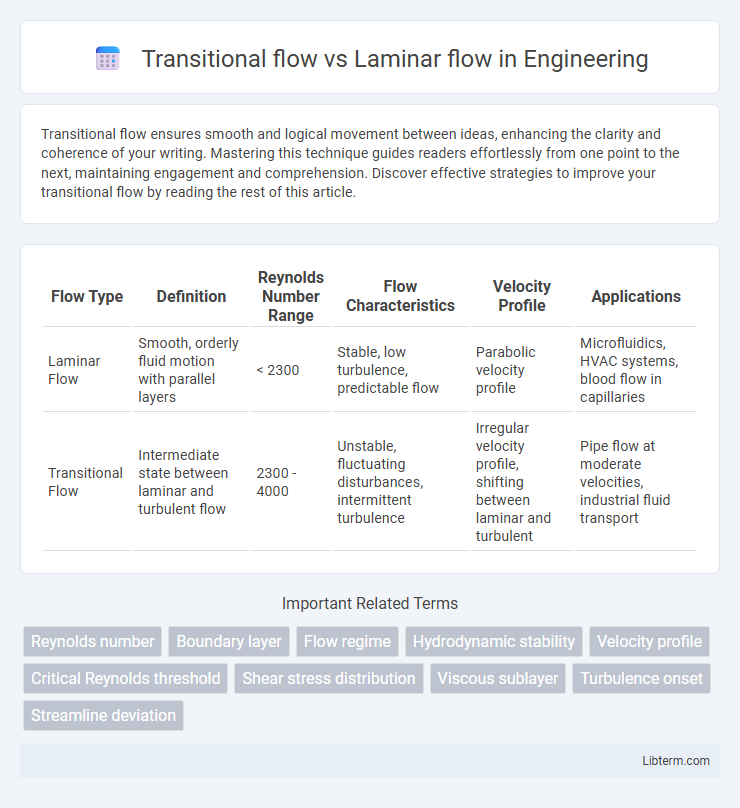

| Flow Type | Definition | Reynolds Number Range | Flow Characteristics | Velocity Profile | Applications |

|---|---|---|---|---|---|

| Laminar Flow | Smooth, orderly fluid motion with parallel layers | < 2300 | Stable, low turbulence, predictable flow | Parabolic velocity profile | Microfluidics, HVAC systems, blood flow in capillaries |

| Transitional Flow | Intermediate state between laminar and turbulent flow | 2300 - 4000 | Unstable, fluctuating disturbances, intermittent turbulence | Irregular velocity profile, shifting between laminar and turbulent | Pipe flow at moderate velocities, industrial fluid transport |

Introduction to Fluid Flow Regimes

Transitional flow occurs between laminar and turbulent flow regimes, characterized by fluctuating velocity profiles and intermittent disturbances. Laminar flow features smooth, orderly fluid motion with parallel layers and low Reynolds numbers typically below 2,000. Understanding these flow regimes is crucial for predicting fluid behavior in engineering applications such as pipeline transport and aerodynamic design.

Defining Laminar Flow

Laminar flow is characterized by smooth, parallel layers of fluid moving with minimal mixing and low Reynolds numbers typically below 2,000. This flow type ensures predictable velocity profiles and reduced turbulence, essential for precise engineering and aerodynamic applications. Transitional flow occurs between laminar and turbulent states, marked by increasing instability and fluctuations as Reynolds numbers approach 2,300 to 4,000.

Characteristics of Transitional Flow

Transitional flow exhibits fluctuating velocity and pressure patterns between laminar and turbulent states, typically occurring at Reynolds numbers between 2,000 and 4,000. It features intermittent bursts of turbulence amidst laminar streaks, causing unstable and unpredictable fluid motion. This flow regime significantly affects heat transfer and friction characteristics, often complicating engineering calculations and design.

Reynolds Number: The Key Differentiator

Reynolds number is the critical parameter distinguishing transitional flow from laminar flow, quantifying the ratio of inertial forces to viscous forces in a fluid. Laminar flow occurs at low Reynolds numbers, typically below 2,300, where fluid particles move in smooth, orderly layers with minimal mixing. Transitional flow arises between Reynolds numbers of approximately 2,300 and 4,000, marking the onset of instabilities and fluctuating flow patterns before the fully turbulent regime begins.

Visual and Practical Differences

Transitional flow exhibits intermittent fluctuations and vortices, creating visible eddies and unsteady fluid motion, whereas laminar flow displays smooth, parallel streamlines with minimal mixing and uniform velocity profile. Practically, transitional flow increases drag and heat transfer rates compared to the predictable, low-resistance behavior of laminar flow, which is favored in precision fluid dynamics applications. Visual indicators of transitional flow include irregular velocity patterns and noise, while laminar flow appears clear and steady, often observed in controlled microfluidic systems.

Factors Influencing Flow Transition

Flow transition from laminar to transitional is primarily influenced by Reynolds number, surface roughness, and flow velocity. Higher Reynolds numbers increase instability, promoting transition, while smoother surfaces and lower velocities tend to maintain laminar flow. External disturbances, such as vibrations and temperature gradients, also play a critical role in triggering transitional flow conditions.

Applications of Laminar Flow

Laminar flow is characterized by smooth, orderly fluid motion, making it essential in applications requiring minimal turbulence and particle contamination, such as cleanrooms, medical device manufacturing, and microfluidic devices. Its predictable flow behavior is crucial for processes like chemical vapor deposition and precision printing technologies, where uniform fluid distribution improves product quality. Industries relying on sterile environments benefit from laminar flow systems that control airflow and reduce microbial contamination risks effectively.

Significance of Transitional Flow in Engineering

Transitional flow occurs between laminar and turbulent regimes, significantly impacting fluid dynamics in engineering applications such as pipeline design, aerodynamic surfaces, and heat exchangers. Understanding transitional flow is crucial for predicting pressure drops, enhancing energy efficiency, and preventing flow-induced vibrations or noise in mechanical systems. Engineers use computational fluid dynamics (CFD) models and experimental data to identify the onset of transitional flow and optimize system performance accordingly.

Challenges in Managing Flow Regimes

Managing transitional flow poses significant challenges due to its unpredictable behavior between laminar and turbulent states, causing difficulties in accurate modeling and flow control. Laminar flow offers predictable patterns with low friction, but even slight disturbances can trigger transitions, complicating system stability. Engineers face challenges in designing surfaces and control mechanisms that maintain laminar flow or effectively handle fluctuations during the transitional phase to optimize performance and minimize energy losses.

Summary: Comparing Transitional and Laminar Flow

Transitional flow occurs between laminar and turbulent regimes, characterized by fluctuating velocity and increased mixing, typically seen at Reynolds numbers between 2,000 and 4,000 in pipe flow. Laminar flow maintains smooth, orderly fluid motion with parallel layers, exhibiting low Reynolds numbers below 2,000, minimizing shear stress and energy dissipation. Understanding these differences is crucial for optimizing fluid dynamics in engineering applications such as pipeline design and aerodynamic performance.

Transitional flow Infographic

libterm.com

libterm.com