Electrical actuation converts electrical energy into mechanical motion, enabling precise control in various applications from robotics to automotive systems. This technology offers high efficiency, rapid response times, and simplified integration with electronic control systems. Discover how electrical actuation can optimize your systems by exploring the detailed insights in the rest of this article.

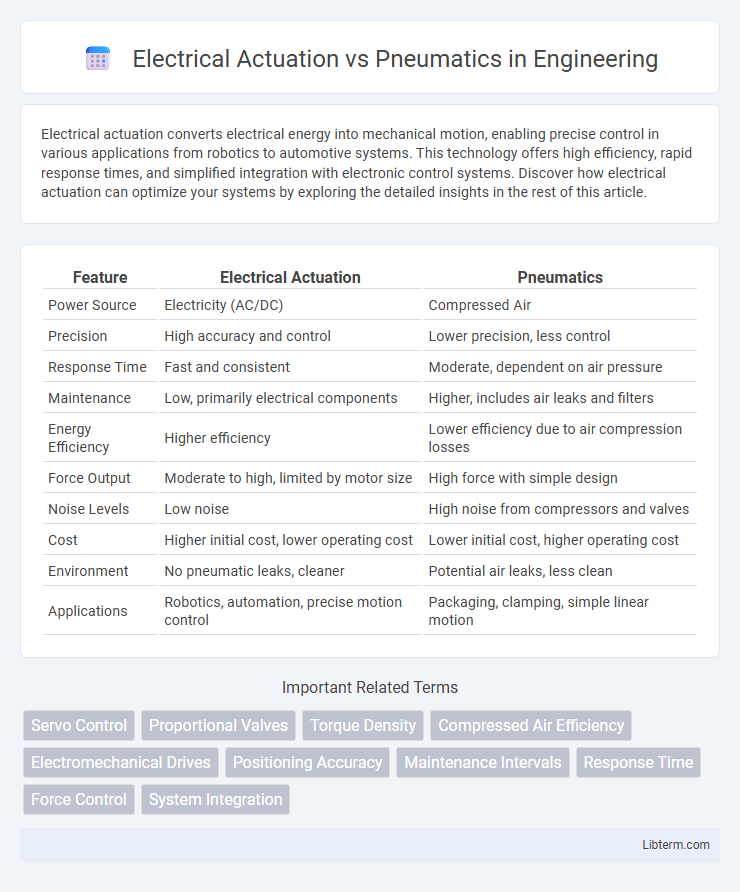

Table of Comparison

| Feature | Electrical Actuation | Pneumatics |

|---|---|---|

| Power Source | Electricity (AC/DC) | Compressed Air |

| Precision | High accuracy and control | Lower precision, less control |

| Response Time | Fast and consistent | Moderate, dependent on air pressure |

| Maintenance | Low, primarily electrical components | Higher, includes air leaks and filters |

| Energy Efficiency | Higher efficiency | Lower efficiency due to air compression losses |

| Force Output | Moderate to high, limited by motor size | High force with simple design |

| Noise Levels | Low noise | High noise from compressors and valves |

| Cost | Higher initial cost, lower operating cost | Lower initial cost, higher operating cost |

| Environment | No pneumatic leaks, cleaner | Potential air leaks, less clean |

| Applications | Robotics, automation, precise motion control | Packaging, clamping, simple linear motion |

Introduction to Electrical Actuation and Pneumatics

Electrical actuation utilizes electric motors or solenoids to convert electrical energy into precise mechanical movement, offering high efficiency, accuracy, and controllability in various automation applications. Pneumatics relies on compressed air to drive pistons or rotary actuators, providing fast response times and simple design with lower initial costs but limited force control compared to electrical systems. Both technologies are fundamental in industrial automation, with electrical actuation favored for precision tasks and pneumatics preferred for cost-effective, high-speed operations in environments tolerant of air-driven power.

Core Principles of Electrical Actuation

Electrical actuation operates on the principle of converting electrical energy into mechanical motion using components like electric motors, solenoids, or piezoelectric elements. This method offers precise control over position, speed, and force through variable voltage or current inputs, enabling high accuracy and repeatability in automation applications. Unlike pneumatics, electrical actuators provide cleaner operation without the need for compressed air, reducing maintenance and improving system efficiency.

Fundamentals of Pneumatic Systems

Pneumatic systems operate by compressing and controlling air to create mechanical motion, relying on components such as compressors, valves, actuators, and air treatment units to regulate pressure and flow. Fundamentally, pneumatics use stored energy in compressed air to power cylinders and motors, offering fast response and simple maintenance compared to electrical actuation. Key advantages include cost-effectiveness for repetitive linear motion and intrinsic safety in hazardous environments where electrical sparks pose risks.

Efficiency Comparison: Electrical vs Pneumatic

Electrical actuation systems demonstrate higher overall efficiency compared to pneumatic systems, largely due to reduced energy losses during operation and lower power consumption. While pneumatics rely on compressed air generation with significant energy waste and pressure drop, electric actuators convert electrical energy directly into mechanical motion, achieving efficiency rates often exceeding 80%. This efficiency advantage makes electrical actuation more cost-effective for continuous or precise control applications in automation and industrial machinery.

Precision and Control in Motion Systems

Electrical actuation offers superior precision and control in motion systems due to its ability to provide accurate position feedback and fine speed regulation through advanced sensors and digital controllers. Pneumatics, while efficient for rapid movements, generally lack the high-resolution control and repeatability required for applications demanding exact positioning and smooth motion profiles. The integration of servo motors and electronic drives in electrical actuation enables complex, programmable motion sequences that pneumatic systems cannot consistently achieve.

Maintenance and Reliability Factors

Electrical actuation systems typically offer higher reliability and lower maintenance requirements due to fewer mechanical components and absence of leaks compared to pneumatic systems. Pneumatics rely on compressed air, which can introduce contamination and require regular inspection of hoses, valves, and seals to maintain optimal performance. The longevity of electrical actuators is enhanced by precision control and minimal wear, whereas pneumatic actuators may experience more frequent downtime due to air supply inconsistencies and component fatigue.

Cost Analysis: Installation and Operating Expenses

Electrical actuation typically incurs higher initial installation costs due to complex wiring and control system requirements, whereas pneumatic systems benefit from simpler piping and lower setup expenses. Operating costs for electrical actuators are generally lower, driven by higher energy efficiency and reduced maintenance needs compared to pneumatic systems, which require ongoing air compressor energy consumption and regular leak repairs. Lifecycle cost analysis often favors electrical actuation in applications with frequent cycling and precise control demands, despite the upfront investment.

Safety Considerations in Industrial Environments

Electrical actuation systems offer enhanced safety features such as precise control, reduced risk of leaks, and integration with advanced monitoring technologies, making them suitable for hazardous industrial environments. Pneumatic systems, while robust and simple, pose risks related to compressed air leaks, potential for sudden pressure loss, and challenges in maintaining consistent control, which can lead to safety incidents. Proper maintenance, adherence to safety standards, and choosing the appropriate actuation method based on environmental hazards are critical for minimizing risks in industrial settings.

Environmental Impact and Sustainability

Electrical actuation systems offer higher energy efficiency and reduced greenhouse gas emissions compared to pneumatic systems, which often rely on compressed air generated by energy-intensive compressors. Pneumatics typically consume more energy due to continuous air leakage and require oil-laden lubricants, contributing to environmental pollution and hazardous waste. Sustainable manufacturing increasingly favors electrical actuators for their lower carbon footprint, longer lifespan, and compatibility with renewable energy sources.

Application Suitability: Choosing the Right System

Electrical actuation offers precise control and is ideal for applications requiring accurate positioning and variable speed, such as robotics and automation in manufacturing. Pneumatic systems excel in environments needing rapid, repetitive motion with simpler control, often used in packaging and material handling industries. Selecting the right system depends on factors like required force, speed, environmental conditions, and maintenance capabilities.

Electrical Actuation Infographic

libterm.com

libterm.com