Computational simulation harnesses advanced algorithms and high-performance computing to model complex systems and predict their behavior under various scenarios. It enables researchers and engineers to analyze processes in fields such as physics, biology, and engineering without costly physical experiments. Discover how computational simulation can transform your approach by exploring the full article.

Table of Comparison

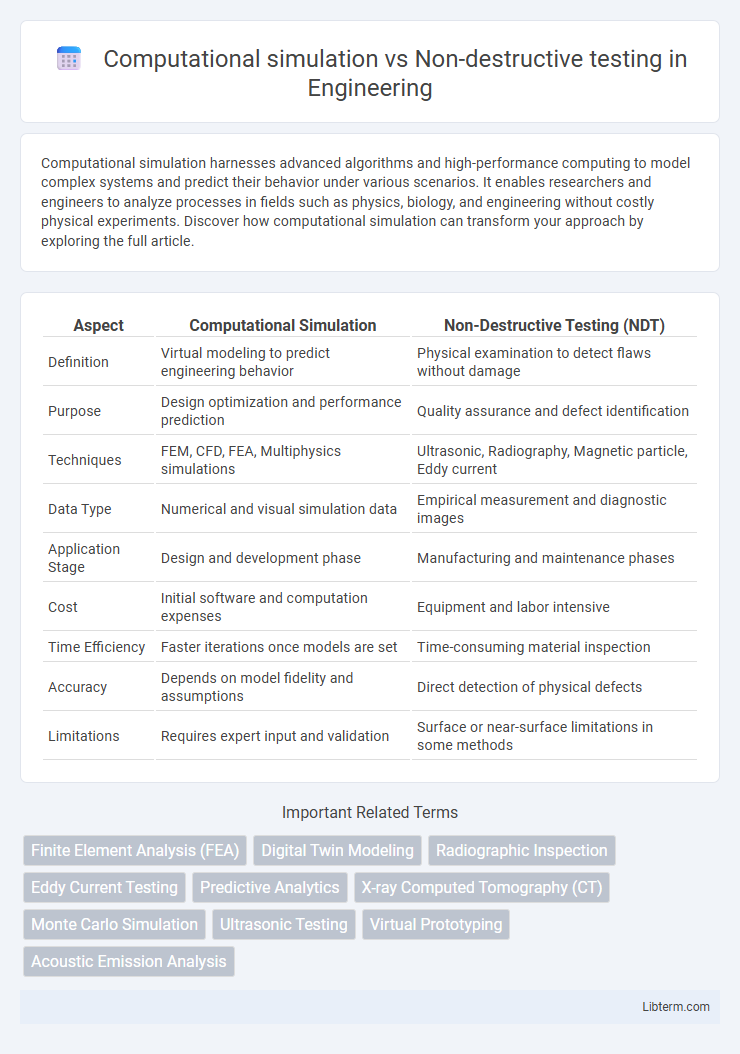

| Aspect | Computational Simulation | Non-Destructive Testing (NDT) |

|---|---|---|

| Definition | Virtual modeling to predict engineering behavior | Physical examination to detect flaws without damage |

| Purpose | Design optimization and performance prediction | Quality assurance and defect identification |

| Techniques | FEM, CFD, FEA, Multiphysics simulations | Ultrasonic, Radiography, Magnetic particle, Eddy current |

| Data Type | Numerical and visual simulation data | Empirical measurement and diagnostic images |

| Application Stage | Design and development phase | Manufacturing and maintenance phases |

| Cost | Initial software and computation expenses | Equipment and labor intensive |

| Time Efficiency | Faster iterations once models are set | Time-consuming material inspection |

| Accuracy | Depends on model fidelity and assumptions | Direct detection of physical defects |

| Limitations | Requires expert input and validation | Surface or near-surface limitations in some methods |

Introduction to Computational Simulation and Non-Destructive Testing

Computational simulation uses mathematical models and algorithms to predict the behavior and performance of materials or structures under various conditions, enabling virtual testing and optimization without physical damage. Non-destructive testing (NDT) involves techniques such as ultrasonic, radiographic, and magnetic particle inspection to evaluate the integrity and properties of materials or components without impairing their future usability. Both methods are essential in industries like aerospace, manufacturing, and construction for ensuring safety, reliability, and quality control.

Defining Computational Simulation in Engineering

Computational simulation in engineering involves using mathematical models and computer algorithms to replicate the behavior of physical systems under various conditions, enabling precise analysis and optimization without physical prototypes. This approach allows engineers to predict performance, identify potential failures, and refine designs efficiently, reducing time and costs associated with experimental testing. Unlike non-destructive testing, which physically inspects materials and components without damage, computational simulation provides a virtual environment to explore scenarios difficult or impossible to recreate in reality.

Overview of Non-Destructive Testing Methods

Non-destructive testing (NDT) methods include ultrasonic testing, radiographic testing, magnetic particle testing, and eddy current testing, each designed to evaluate material integrity without causing damage. These techniques detect surface and subsurface flaws by analyzing material responses to physical stimuli such as sound waves, electromagnetic fields, or radiation. NDT is essential for quality control, safety inspections, and preventive maintenance across industries like aerospace, manufacturing, and infrastructure.

Key Differences Between Simulation and NDT

Computational simulation uses mathematical models and algorithms to predict material behavior and structural performance, allowing virtual testing under various conditions without physical samples. Non-destructive testing (NDT) involves physical examination techniques like ultrasonic, radiographic, or magnetic particle testing to detect defects or measure properties without damaging the material. The key difference lies in simulation's predictive, model-based approach versus NDT's empirical, data-driven assessment of real-world samples.

Advantages of Computational Simulation

Computational simulation offers significant advantages over non-destructive testing (NDT) by enabling detailed analysis of complex systems without physical intervention, reducing costs and testing time. It allows for the prediction of performance under various conditions, enhanced design optimization, and early detection of potential failures through virtual models. This approach supports iterative improvements and scalability, making it indispensable for risk assessment and reliability enhancement in engineering applications.

Benefits of Non-Destructive Testing Techniques

Non-Destructive Testing (NDT) techniques provide accurate material and structural integrity assessments without altering or damaging the test subject, enabling repeated inspections and prolonged asset life. NDT methods such as ultrasonic testing, radiography, and magnetic particle testing reveal subsurface defects and surface discontinuities that computational simulations may overlook due to model limitations or assumptions. These techniques improve safety by detecting early signs of failure, reducing downtime, and supporting compliance with industry standards more effectively than purely simulation-based approaches.

Limitations and Challenges of Each Approach

Computational simulation faces limitations such as the need for accurate material properties and boundary conditions, which can lead to errors in predicting real-world behavior, while high computational costs and complex model validation processes challenge its effectiveness. Non-destructive testing (NDT) methods encounter difficulties in detecting subsurface defects with limited resolution, operator dependency, and constraints in inspecting complex geometries or large structures. Both approaches require careful integration to compensate for their individual shortcomings, ensuring comprehensive evaluation in engineering applications.

Selecting the Right Method for Structural Assessment

Selecting the right method for structural assessment depends on project goals, accuracy requirements, and resource availability. Computational simulation offers detailed predictive models using finite element analysis and material behavior algorithms, ideal for design optimization and scenario testing without physical intervention. Non-destructive testing (NDT) provides real-world condition evaluations through methods like ultrasonic testing, radiography, and magnetic particle inspection, ensuring safety and integrity without damaging the structure.

Integrating Simulation and NDT for Enhanced Results

Integrating computational simulation with non-destructive testing (NDT) enhances defect detection accuracy and structural integrity assessment by combining predictive modeling with real-time inspection data. Simulation tools, such as finite element analysis (FEA) and computational fluid dynamics (CFD), optimize NDT procedures by identifying critical inspection zones and refining sensor placement. This synergy reduces testing costs, minimizes downtime, and improves reliability in aerospace, automotive, and civil engineering applications.

Future Trends in Simulation and Non-Destructive Testing

Future trends in computational simulation and non-destructive testing (NDT) emphasize the integration of artificial intelligence and machine learning to enhance predictive accuracy and defect detection. Advanced digital twins combined with real-time sensor data are transforming maintenance strategies by enabling proactive interventions and reducing downtime. The convergence of augmented reality with NDT techniques is set to improve on-site inspections by providing immersive visualization and instant data analysis.

Computational simulation Infographic

libterm.com

libterm.com