Steady flow refers to a fluid motion where velocity at any given point remains constant over time, ensuring uniform conditions throughout the system. This concept is crucial in engineering applications involving pipes, channels, and airflows to predict and control fluid behavior accurately. Explore the following article to understand how steady flow impacts your fluid dynamics projects.

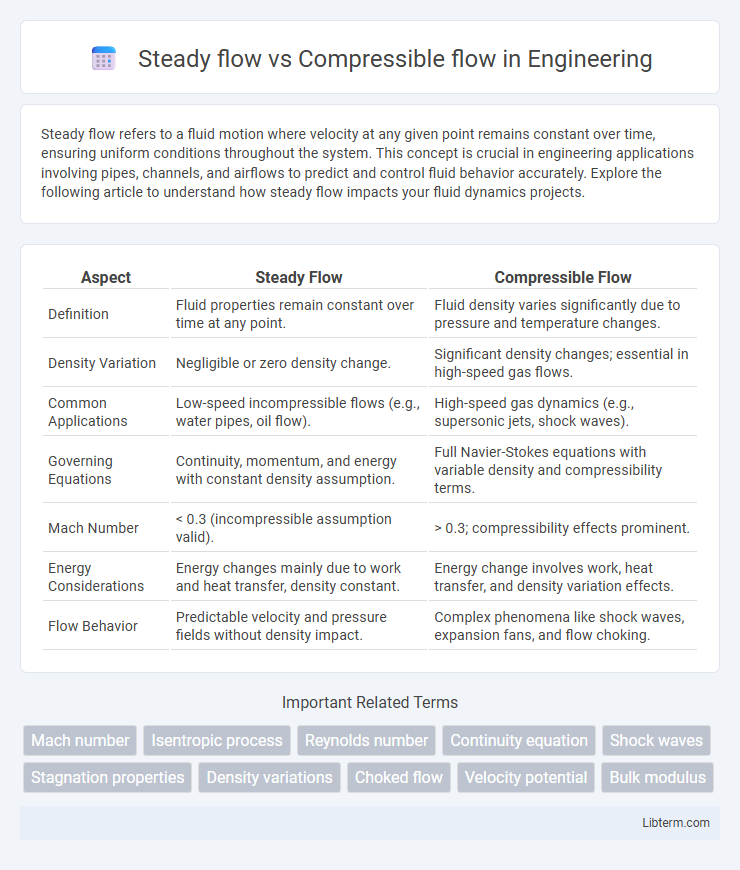

Table of Comparison

| Aspect | Steady Flow | Compressible Flow |

|---|---|---|

| Definition | Fluid properties remain constant over time at any point. | Fluid density varies significantly due to pressure and temperature changes. |

| Density Variation | Negligible or zero density change. | Significant density changes; essential in high-speed gas flows. |

| Common Applications | Low-speed incompressible flows (e.g., water pipes, oil flow). | High-speed gas dynamics (e.g., supersonic jets, shock waves). |

| Governing Equations | Continuity, momentum, and energy with constant density assumption. | Full Navier-Stokes equations with variable density and compressibility terms. |

| Mach Number | < 0.3 (incompressible assumption valid). | > 0.3; compressibility effects prominent. |

| Energy Considerations | Energy changes mainly due to work and heat transfer, density constant. | Energy change involves work, heat transfer, and density variation effects. |

| Flow Behavior | Predictable velocity and pressure fields without density impact. | Complex phenomena like shock waves, expansion fans, and flow choking. |

Introduction to Steady Flow and Compressible Flow

Steady flow occurs when fluid properties such as velocity, pressure, and density at any given point remain constant over time, often assumed in incompressible fluid dynamics. Compressible flow involves significant changes in fluid density due to pressure and temperature variations, typically observed in gases moving at high velocities or under large pressure gradients. Understanding steady and compressible flow is critical for designing efficient aerodynamic components, gas pipelines, and high-speed propulsion systems.

Fundamental Principles of Fluid Flow

Steady flow refers to fluid motion where properties such as velocity, pressure, and density remain constant at any given point over time, simplifying the application of the continuity, momentum, and energy equations. Compressible flow involves significant changes in fluid density, typically occurring at high velocities close to or exceeding the speed of sound, requiring the inclusion of compressibility effects in fundamental equations like the Navier-Stokes and energy conservation equations. Understanding the distinction between steady and compressible flow is crucial for accurate modeling of fluid dynamics in applications ranging from aerodynamics to pipeline transport.

Defining Steady Flow: Characteristics and Examples

Steady flow is characterized by fluid properties such as velocity, pressure, and density remaining constant at any given point over time, indicating no temporal variations in the flow field. This behavior is typical in many engineering applications, such as water flowing steadily through a pipe or air moving at a constant velocity inside a duct under incompressible flow conditions. Understanding steady flow is crucial for analyzing fluid systems where the assumption of time-invariant conditions simplifies mathematical modeling and design calculations.

Understanding Compressible Flow: Key Concepts

Compressible flow refers to fluid motion where density variations are significant due to pressure and temperature changes, commonly occurring in gases at high velocities near or above the speed of sound. Key concepts include Mach number, which quantifies flow speed relative to sound speed, and shock waves, abrupt pressure changes that dramatically affect flow properties. Understanding these principles is essential for analyzing aerodynamic performance, supersonic flight, and gas dynamics in engineering applications.

Mathematical Formulation: Steady vs Compressible Flow

Steady flow assumes constant flow properties at any given point over time, allowing simplification of the Navier-Stokes equations by eliminating time-dependent terms, resulting in /t = 0. Compressible flow requires solving the full Navier-Stokes equations with density variations included, often involving the continuity equation r/t + *(ru) = 0 and energy equation to account for variable density, pressure, and temperature. The mathematical formulation of steady flow typically uses incompressible flow assumptions (constant density), while compressible flow demands coupled nonlinear partial differential equations to model variable fluid properties dynamically.

Major Differences between Steady and Compressible Flows

Steady flow refers to fluid motion where velocity, pressure, and density at any point remain constant over time, while compressible flow involves significant changes in fluid density due to variations in velocity and pressure, often observed at high speeds near or above Mach 0.3. In steady flow, the fluid properties are time-independent, contrasting with compressible flow where density variations affect flow properties dynamically, leading to phenomena like shock waves and expansion fans. Compressible flow analysis requires solving the conservation equations with variable density, unlike steady, incompressible flow which assumes constant density simplifying the governing equations.

Applications of Steady Flow in Engineering

Steady flow, characterized by constant flow parameters over time, is crucial in the design of hydraulic systems, pipelines, and HVAC installations where predictable fluid behavior ensures operational efficiency. Applications in pump systems and water distribution networks benefit from steady flow to maintain consistent pressure and flow rates, minimizing energy losses. Engineers leverage steady flow principles in wind tunnel testing to simulate aerodynamic conditions, enabling precise performance evaluations of aircraft and automotive designs.

Real-World Scenarios Involving Compressible Flow

Real-world scenarios involving compressible flow include high-speed aerodynamics, such as supersonic aircraft and rocket propulsion, where air density changes significantly due to rapid velocity variations. Gas pipelines and compressors also exhibit compressible flow behavior, demanding precise control of pressure and temperature to prevent shock waves and ensure efficiency. Understanding compressible flow is crucial in designing HVAC systems and turbines, where varying fluid density impacts performance and safety.

Advantages and Limitations of Each Flow Type

Steady flow offers advantages such as predictable velocity and pressure fields, enabling simplified analysis and design in engineering applications, while its limitation lies in its inapplicability to rapidly changing or unsteady conditions. Compressible flow advantages include accurate modeling of high-speed gas dynamics and shock waves critical in aerospace and propulsion systems, but it poses challenges due to complex equations and significant density variations that complicate calculations. Understanding the trade-offs between steady and compressible flows aids in selecting appropriate models for fluid dynamics problems involving different velocity and pressure regimes.

Conclusion: Selecting the Appropriate Flow Model

Choosing the appropriate flow model depends on the flow characteristics and application requirements. Steady flow models are ideal for incompressible fluids with constant density and velocity fields, commonly found in liquids and low-speed gases. Compressible flow models are essential for high-speed gas flows where significant density changes occur, such as in aerodynamics and gas dynamics applications.

Steady flow Infographic

libterm.com

libterm.com