The Morrow diagram is a vital tool in fatigue analysis used to predict the lifespan of materials under cyclic loading by accounting for mean stress effects. It enhances the accuracy of fatigue life estimations by modifying the stress amplitude based on the mean stress, offering engineers valuable insights into material performance. Discover how the Morrow diagram can improve your fatigue assessment in the full article ahead.

Table of Comparison

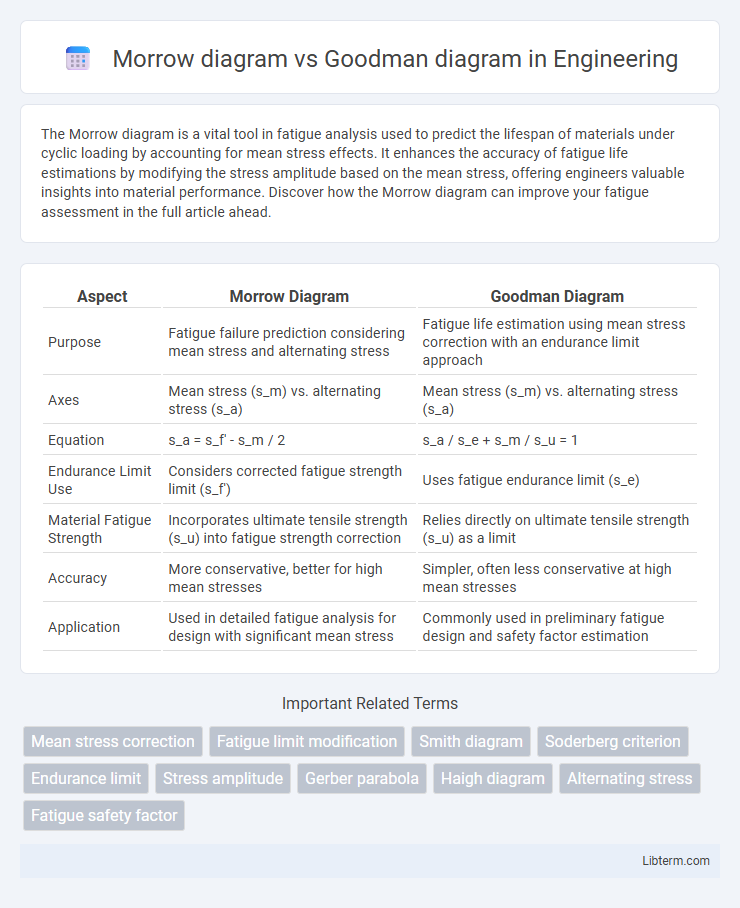

| Aspect | Morrow Diagram | Goodman Diagram |

|---|---|---|

| Purpose | Fatigue failure prediction considering mean stress and alternating stress | Fatigue life estimation using mean stress correction with an endurance limit approach |

| Axes | Mean stress (s_m) vs. alternating stress (s_a) | Mean stress (s_m) vs. alternating stress (s_a) |

| Equation | s_a = s_f' - s_m / 2 | s_a / s_e + s_m / s_u = 1 |

| Endurance Limit Use | Considers corrected fatigue strength limit (s_f') | Uses fatigue endurance limit (s_e) |

| Material Fatigue Strength | Incorporates ultimate tensile strength (s_u) into fatigue strength correction | Relies directly on ultimate tensile strength (s_u) as a limit |

| Accuracy | More conservative, better for high mean stresses | Simpler, often less conservative at high mean stresses |

| Application | Used in detailed fatigue analysis for design with significant mean stress | Commonly used in preliminary fatigue design and safety factor estimation |

Introduction to Fatigue Analysis in Engineering

The Morrow diagram and Goodman diagram are essential tools in fatigue analysis for engineering, used to predict material failure under cyclic loading by illustrating the relationship between mean stress and alternating stress. The Goodman diagram provides a conservative linear failure criterion based on ultimate tensile strength, while the Morrow diagram incorporates the material's fatigue strength and mean stress to offer a more accurate fatigue life prediction. Engineers leverage these diagrams to design components that withstand fluctuating stresses, optimizing durability and safety in mechanical and structural applications.

Overview of the Morrow Diagram

The Morrow diagram illustrates the relationship between mean stress and alternating stress to predict fatigue life, incorporating mean stress effects more conservatively than the Goodman diagram. It uses a linear envelope connecting the endurance limit and ultimate tensile strength, emphasizing the role of mean stress in reducing fatigue strength. This approach provides a more accurate fatigue life estimation for materials subjected to varying mean and alternating stresses.

Overview of the Goodman Diagram

The Goodman diagram is a graphical representation used in fatigue analysis to evaluate the relationship between mean stress and alternating stress for materials subjected to cyclic loading. It plots the alternating stress against the mean stress, typically using a straight line connecting the fatigue limit at zero mean stress to the ultimate tensile strength at zero alternating stress. This diagram helps engineers predict fatigue failure by providing a conservative failure criterion, especially useful in design scenarios involving fluctuating stresses.

Key Concepts: Mean Stress and Alternating Stress

Morrow and Goodman diagrams are critical tools in fatigue analysis, differentiating primarily in how they account for mean stress and alternating stress. The Morrow diagram incorporates mean stress by adjusting the fatigue limit based on the mean stress value, emphasizing the material's endurance limit under tension-compression cycles. The Goodman diagram simplifies this relationship by linearly connecting the ultimate tensile strength with the alternating stress, offering a conservative estimate for fatigue failure under varying mean stress conditions.

Assumptions Behind Morrow and Goodman Methods

The Morrow diagram assumes a linear damage accumulation model with mean stress effects accounted for by a modified alternating stress line intersecting the fatigue limit at zero mean stress. The Goodman diagram is based on a conservative linear relationship between alternating stress and mean stress, assuming failure occurs when the combined stress ratio exceeds material endurance limits. Both methods presume isotropic material behavior and fully reversed loading conditions, but Morrow's approach integrates mean stress influence more accurately for ductile materials under cyclic loading.

Mathematical Formulation and Equations

Morrow diagram and Goodman diagram represent different fatigue failure criteria based on mean stress and alternating stress relationships. The Morrow equation considers both tensile and compressive mean stresses using the formulation \(\frac{\sigma_a}{\sigma'_f} + \frac{\sigma_m}{\sigma_y} = 1\), where \(\sigma_a\) is the alternating stress, \(\sigma_m\) is the mean stress, \(\sigma'_f\) is the fatigue strength coefficient, and \(\sigma_y\) is the yield strength. The Goodman equation employs a linear relation \(\frac{\sigma_a}{\sigma_f} + \frac{\sigma_m}{\sigma_u} = 1\), where \(\sigma_f\) is the fatigue limit and \(\sigma_u\) is the ultimate tensile strength, primarily addressing tensile mean stresses.

Practical Applications in Industry

Morrow and Goodman diagrams are essential tools in fatigue analysis, with Morrow's approach providing a more conservative estimate by considering mean stress effects on fatigue life, crucial for designing components in aerospace and automotive industries where safety margins are tight. Goodman diagrams are widely employed in civil engineering and machine design to assess alternating stress limits and ensure structural integrity under variable loading conditions. Both models facilitate the optimization of material usage and lifecycle predictions, directly impacting maintenance schedules and cost-efficiency in industrial applications.

Comparative Advantages and Limitations

The Morrow diagram excels in fatigue analysis by incorporating mean stress effects alongside alternating stress, providing a more comprehensive evaluation of material fatigue under varying load conditions compared to the Goodman diagram. The Goodman diagram is simpler and widely used, emphasizing the relationship between mean stress and alternating stress with a straight-line approximation, which can result in conservative design estimates. Limitations of the Morrow diagram include increased complexity and the need for more material data, while the Goodman diagram may overlook more nuanced stress interactions, potentially leading to less accurate fatigue life predictions.

Selection Criteria: When to Use Morrow vs Goodman

The Morrow diagram is preferred for fatigue analysis when mean stress effects are significant and a conservative estimate of material endurance is required, especially under tensile mean stresses. The Goodman diagram is more suitable for design scenarios involving alternating stresses with zero or compressive mean stresses, offering a simpler approach for safe life predictions. Selection depends on the loading conditions and accuracy needed, with Morrow providing detailed mean stress correction and Goodman offering straightforward design limits.

Conclusion and Future Directions in Fatigue Analysis

Morrow and Goodman diagrams provide critical frameworks for fatigue analysis by relating mean stress and alternating stress to material endurance, with Morrow's approach offering more accurate predictions under tensile mean stresses while Goodman's is conservative and easier to apply. Future research aims to integrate advanced probabilistic models and machine learning techniques to refine fatigue life predictions, accounting for variable loading and complex material behaviors. Emphasizing multi-scale analysis and real-time monitoring will further enhance the reliability of fatigue assessments in engineering applications.

Morrow diagram Infographic

libterm.com

libterm.com