Mixed-flow pumps combine the benefits of axial and radial flow, offering high efficiency and moderate pressure output ideal for various industrial and irrigation applications. Their design allows for versatile performance in handling large volumes of fluid with reduced energy consumption. Discover how mixed-flow technology can enhance Your pumping system by exploring the rest of the article.

Table of Comparison

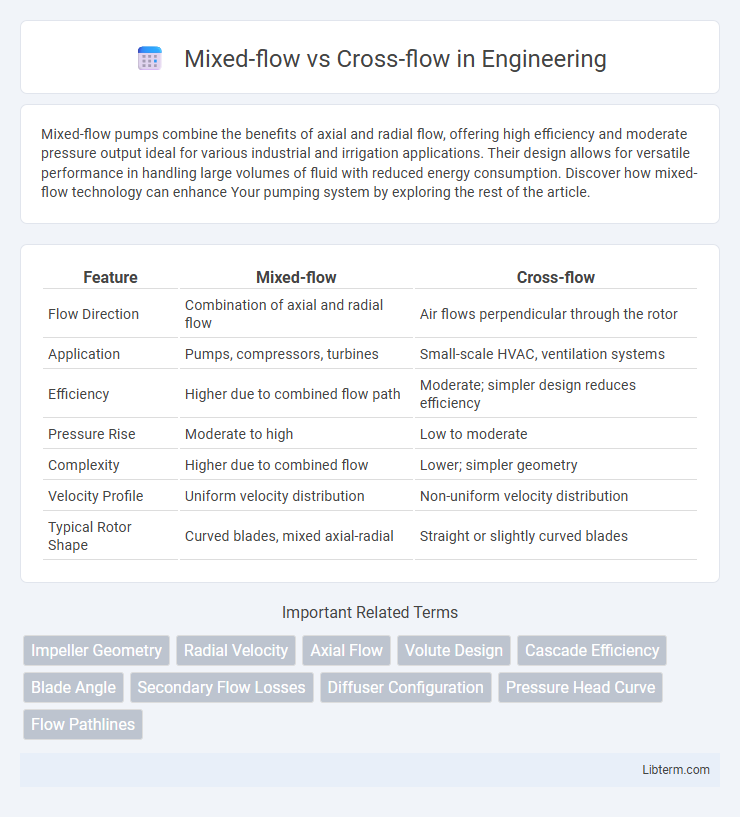

| Feature | Mixed-flow | Cross-flow |

|---|---|---|

| Flow Direction | Combination of axial and radial flow | Air flows perpendicular through the rotor |

| Application | Pumps, compressors, turbines | Small-scale HVAC, ventilation systems |

| Efficiency | Higher due to combined flow path | Moderate; simpler design reduces efficiency |

| Pressure Rise | Moderate to high | Low to moderate |

| Complexity | Higher due to combined flow | Lower; simpler geometry |

| Velocity Profile | Uniform velocity distribution | Non-uniform velocity distribution |

| Typical Rotor Shape | Curved blades, mixed axial-radial | Straight or slightly curved blades |

Introduction to Mixed-flow and Cross-flow Systems

Mixed-flow systems combine the characteristics of axial and radial flow, allowing air or fluid to move both parallel and perpendicular to the axis, resulting in higher efficiency and improved pressure recovery. Cross-flow systems direct fluid or air perpendicularly across a heat exchanger or filter, optimizing surface area utilization and enhancing heat transfer or filtration performance. Both systems are widely used in HVAC, turbochargers, and cooling applications to balance flow dynamics and energy efficiency.

Fundamental Principles of Mixed-flow Design

Mixed-flow fans combine axial and radial flow patterns, drawing air axially and expelling it radially, enhancing pressure and flow capacity compared to pure axial or radial fans. The fundamental principle of mixed-flow design involves an impeller with blades oriented to create a diagonal airflow path, optimizing both velocity and pressure for efficient performance. This hybrid flow pattern reduces energy consumption while maintaining compact size, making mixed-flow fans suitable for HVAC systems and industrial ventilation where moderate pressure and volume are required.

Core Concepts of Cross-flow Mechanics

Cross-flow mechanics involve fluid moving perpendicular to the fan or turbine blade rotation, facilitating effective heat transfer and uniform airflow distribution in applications like heat exchangers and ventilation systems. Unlike mixed-flow designs, cross-flow systems capitalize on a consistent velocity profile and enhanced pressure stability, optimizing performance in cooling and air handling units. Understanding vortex formation and flow separation in cross-flow is crucial for maximizing efficiency and minimizing energy losses in thermal management technologies.

Key Differences Between Mixed-flow and Cross-flow

Mixed-flow fans combine axial and radial airflow patterns, offering higher pressure capabilities and more compact designs compared to cross-flow fans, which direct air perpendicular to the intake, providing uniform airflow distribution across wide openings. Mixed-flow fans are typically used in applications requiring moderate pressure and high airflow rates, such as HVAC systems, while cross-flow fans excel in even air distribution for cooling electronic components and appliances. The key differences lie in airflow direction, pressure generation, and application suitability, with mixed-flow fans delivering higher efficiency in ducted systems and cross-flow fans optimizing airflow uniformity over broad surfaces.

Performance Comparison: Efficiency and Output

Mixed-flow fans typically offer higher efficiency and greater airflow output compared to cross-flow fans, making them ideal for applications requiring robust ventilation with moderate pressure. Cross-flow fans excel in uniform air distribution and quieter operation but generally deliver lower static pressure and reduced airflow efficiency. The choice between the two depends on the balance between performance demands for efficiency, output, and noise levels in specific industrial or HVAC settings.

Applications in Industry: Where Each Excels

Mixed-flow fans excel in industries requiring high-pressure airflow with moderate volume, such as HVAC systems, industrial drying, and cooling towers, due to their efficient balance between axial and centrifugal flow characteristics. Cross-flow fans are preferred in air curtains, electronics cooling, and ventilation systems where uniform airflow distribution and low noise levels are critical. The choice between mixed-flow and cross-flow fans hinges on specific operational needs, such as pressure requirements, space constraints, and noise sensitivity in industrial applications.

Advantages of Mixed-flow Configurations

Mixed-flow configurations offer higher pressure rise and increased efficiency compared to cross-flow designs by combining axial and radial flow components. This results in enhanced compactness and reduced noise levels, making them ideal for applications requiring energy-efficient airflow in limited spaces. Mixed-flow compressors also provide better performance over a wider range of operating conditions, improving reliability and adaptability in HVAC and industrial systems.

Benefits of Cross-flow Arrangements

Cross-flow arrangements enhance heat exchanger performance by maintaining a consistent temperature difference between fluids, improving thermal efficiency. This configuration allows for compact designs with lower pressure drops, reducing energy consumption in fluid transport. Cross-flow heat exchangers are versatile in handling varying flow rates and temperatures, making them ideal for diverse industrial applications.

Selection Criteria: Mixed-flow vs Cross-flow

Mixed-flow fans deliver higher pressure and airflow efficiency, making them suitable for applications requiring compact size and moderate static pressure, such as HVAC systems and industrial ventilation. Cross-flow fans provide uniform airflow and lower noise levels, ideal for cooling electronic equipment and air curtains where consistent, gentle air distribution is necessary. Selection criteria should prioritize flow rate, pressure requirements, noise constraints, and spatial limitations to determine the optimal fan type for specific operational environments.

Future Trends in Flow System Technologies

Mixed-flow and cross-flow turbines are evolving rapidly as future trends emphasize enhanced efficiency and adaptability for renewable energy applications. Innovations in materials and digital control systems enable optimized flow dynamics, reducing energy losses and improving performance in variable conditions. Integration with smart grid technologies and AI-driven monitoring promises real-time adjustments, maximizing output and reliability in both mixed-flow and cross-flow systems.

Mixed-flow Infographic

libterm.com

libterm.com