Carburizing is a heat treatment process that enhances the surface hardness of steel by infusing additional carbon into its outer layer. This technique improves wear resistance and fatigue strength, making it ideal for components subjected to high stress. Explore the rest of this article to understand how carburizing can extend the life of your steel parts.

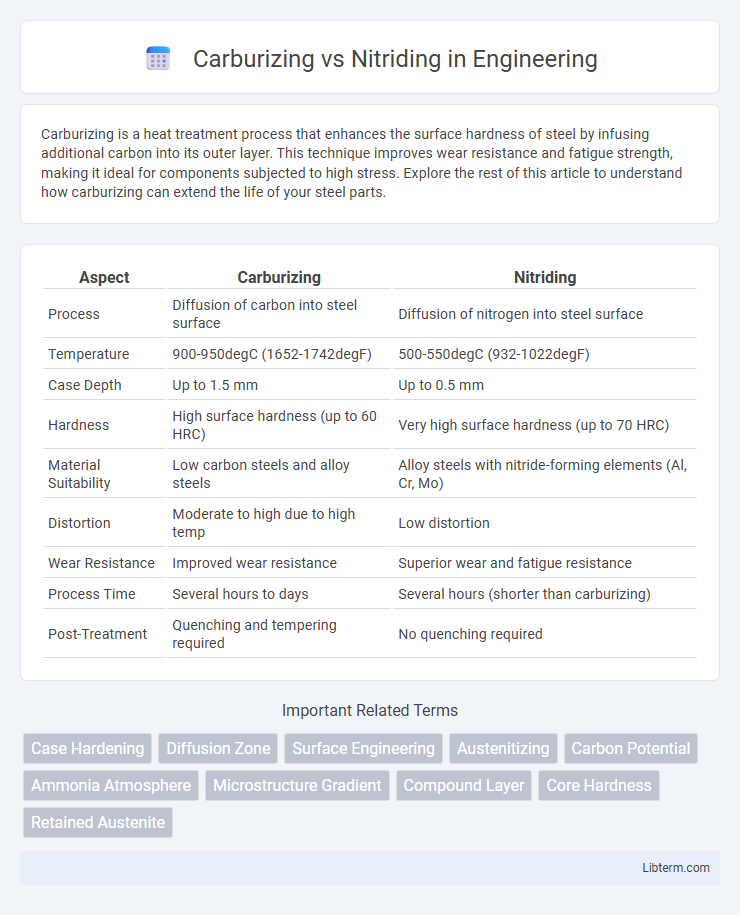

Table of Comparison

| Aspect | Carburizing | Nitriding |

|---|---|---|

| Process | Diffusion of carbon into steel surface | Diffusion of nitrogen into steel surface |

| Temperature | 900-950degC (1652-1742degF) | 500-550degC (932-1022degF) |

| Case Depth | Up to 1.5 mm | Up to 0.5 mm |

| Hardness | High surface hardness (up to 60 HRC) | Very high surface hardness (up to 70 HRC) |

| Material Suitability | Low carbon steels and alloy steels | Alloy steels with nitride-forming elements (Al, Cr, Mo) |

| Distortion | Moderate to high due to high temp | Low distortion |

| Wear Resistance | Improved wear resistance | Superior wear and fatigue resistance |

| Process Time | Several hours to days | Several hours (shorter than carburizing) |

| Post-Treatment | Quenching and tempering required | No quenching required |

Introduction to Surface Hardening Methods

Surface hardening methods enhance the wear resistance and fatigue life of steel components by modifying the outer layer's chemical composition and microstructure. Carburizing diffuses carbon into the steel surface at high temperatures, creating a hard, wear-resistant case while maintaining a tough core. Nitriding introduces nitrogen at lower temperatures, forming hard nitrides that provide excellent wear and corrosion resistance without the need for quenching.

What is Carburizing?

Carburizing is a heat treatment process that introduces carbon into the surface layer of low-carbon steel to increase hardness and wear resistance. The process typically involves heating the steel in a carbon-rich environment, such as furnace atmospheres containing methane or propane, at temperatures ranging from 850degC to 950degC. This surface modification enhances fatigue strength and improves the durability of components like gears and shafts used in automotive and aerospace applications.

What is Nitriding?

Nitriding is a thermochemical surface treatment process that diffuses nitrogen into the metal substrate, typically steel, to enhance hardness, wear resistance, and fatigue strength. Unlike carburizing, which adds carbon, nitriding forms a hard nitride layer without the need for quenching, reducing distortion risks. This process is commonly used in aerospace, automotive, and tooling industries to improve component lifespan and performance.

Key Differences Between Carburizing and Nitriding

Carburizing introduces carbon into the steel surface at high temperatures, resulting in increased hardness and wear resistance, while nitriding diffuses nitrogen into the metal at lower temperatures to form a hard nitride layer with improved fatigue strength and corrosion resistance. Carburizing requires subsequent quenching and tempering processes to achieve desired mechanical properties, whereas nitriding is a low-temperature treatment that does not require quenching. The key difference lies in the elements diffused--carbon for carburizing and nitrogen for nitriding--and their effects on surface hardness, process temperature, and resulting mechanical and chemical properties.

Process Parameters: Temperature, Time, and Atmosphere

Carburizing typically occurs at temperatures between 900degC and 950degC, with process durations ranging from 1 to 24 hours in a carbon-rich atmosphere such as methane or propane. Nitriding operates at lower temperatures, around 500degC to 600degC, requiring longer times of 20 to 100 hours in a nitrogen-rich environment often containing ammonia gas. Control of temperature, time, and atmosphere is crucial in both processes to achieve the desired case depth, hardness, and wear resistance in steel components.

Applications of Carburizing

Carburizing is widely used in the automotive and aerospace industries to enhance surface hardness and wear resistance of low-carbon steel components such as gears, crankshafts, and camshafts. This heat treatment process improves fatigue strength and extends the service life of parts subjected to high stress and friction. Its ability to produce a hard, wear-resistant outer layer while maintaining a tough core makes it ideal for heavy-duty machinery and transmission parts.

Applications of Nitriding

Nitriding is extensively applied in the aerospace, automotive, and tooling industries due to its ability to create hard, wear-resistant surfaces without distortion. Components such as crankshafts, camshafts, gears, and injection molds benefit from nitriding's enhanced fatigue strength and corrosion resistance. Unlike carburizing, nitriding operates at lower temperatures, making it ideal for precision parts requiring dimensional stability.

Material Compatibility for Carburizing vs Nitriding

Carburizing is primarily compatible with low-carbon steels and alloys that require surface hardness improvement without compromising core toughness. Nitriding suits alloy steels rich in aluminum, chromium, and molybdenum, which form hard nitrides during treatment, enhancing wear and fatigue resistance. Material selection for carburizing or nitriding depends on alloy composition, desired mechanical properties, and thermal stability.

Advantages and Disadvantages of Each Method

Carburizing enhances surface hardness and wear resistance by diffusing carbon into steel, but it requires high temperatures and can cause distortion or dimensional changes in parts. Nitriding introduces nitrogen into the surface, producing a hard, wear-resistant layer with minimal distortion and no need for quenching, but it is limited to specific alloy steels and generally results in thinner hardened layers compared to carburizing. Both methods improve fatigue strength, but carburizing offers deeper hardening, while nitriding provides better dimensional stability and corrosion resistance.

Choosing the Right Surface Hardening Process

Choosing the right surface hardening process depends on the specific application requirements, such as desired hardness, wear resistance, and component size. Carburizing enriches the steel surface with carbon, creating a hard, wear-resistant layer suitable for low-carbon steels and parts subjected to heavy shock loads. Nitriding introduces nitrogen into the surface, producing a hard, corrosion-resistant case ideal for alloy steels and components requiring dimensional stability without quenching distortion.

Carburizing Infographic

libterm.com

libterm.com