Thermal load refers to the amount of heat energy that a building or system must manage to maintain optimal temperature and comfort levels. Proper calculation and management of thermal loads are essential for efficient HVAC design and energy conservation. Discover effective strategies to assess and control your thermal load in the full article.

Table of Comparison

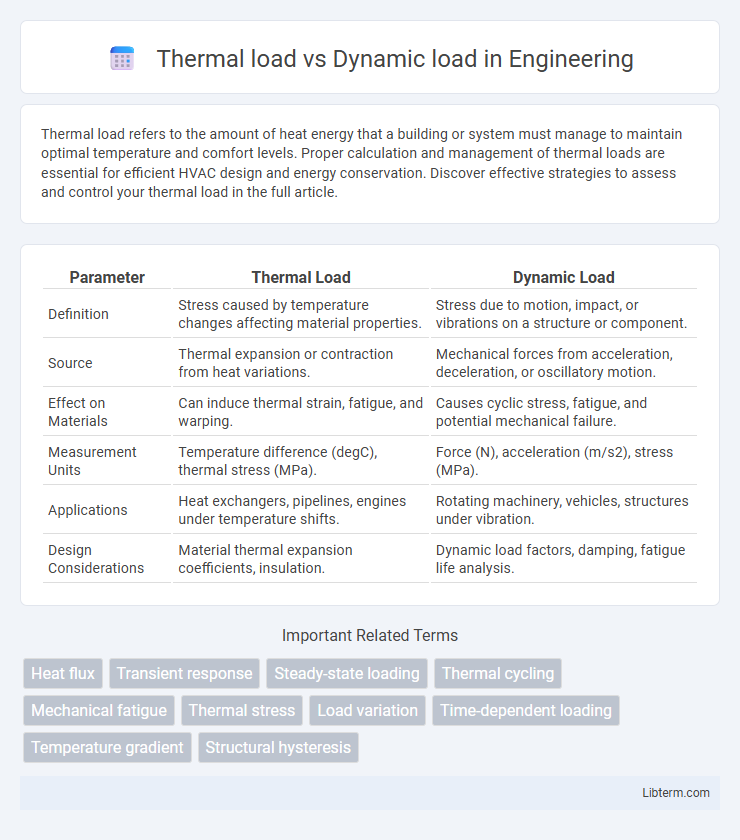

| Parameter | Thermal Load | Dynamic Load |

|---|---|---|

| Definition | Stress caused by temperature changes affecting material properties. | Stress due to motion, impact, or vibrations on a structure or component. |

| Source | Thermal expansion or contraction from heat variations. | Mechanical forces from acceleration, deceleration, or oscillatory motion. |

| Effect on Materials | Can induce thermal strain, fatigue, and warping. | Causes cyclic stress, fatigue, and potential mechanical failure. |

| Measurement Units | Temperature difference (degC), thermal stress (MPa). | Force (N), acceleration (m/s2), stress (MPa). |

| Applications | Heat exchangers, pipelines, engines under temperature shifts. | Rotating machinery, vehicles, structures under vibration. |

| Design Considerations | Material thermal expansion coefficients, insulation. | Dynamic load factors, damping, fatigue life analysis. |

Defining Thermal Load

Thermal load refers to the amount of heat energy transferred to or generated within a system, often measured in watts or BTUs, and it significantly impacts the design of HVAC, electronic, and mechanical systems. Unlike dynamic load, which involves forces causing movement or stress changes, thermal load deals strictly with temperature-related energy changes that affect material expansion, thermal fatigue, and overall system efficiency. Properly defining and managing thermal load is crucial for maintaining operational stability and preventing overheating in critical components.

Understanding Dynamic Load

Dynamic load refers to the time-varying forces acting on a system, often caused by motion, impact, or vibration, which can induce stress and fatigue beyond static conditions. Unlike thermal load, which arises from temperature changes causing expansion or contraction, dynamic load involves varying magnitudes and directions that require robust design to ensure structural integrity and performance. Understanding dynamic load is essential for predicting material behavior and preventing failure in mechanical systems subject to fluctuating forces.

Key Differences Between Thermal and Dynamic Loads

Thermal load refers to the stress or strain on materials caused by temperature changes inducing expansion or contraction, while dynamic load involves forces resulting from motion, impact, or vibration affecting a structure. Thermal loads typically cause gradual deformation due to heat transfer and temperature gradients, whereas dynamic loads generate fluctuating forces that can lead to fatigue and sudden structural failure. Understanding these key differences is crucial in engineering design to ensure materials withstand both thermal expansion and dynamic forces effectively.

Sources of Thermal Load in Engineering

Thermal load in engineering primarily originates from heat generated by friction, electrical resistance, chemical reactions, and environmental temperature variations. These sources cause expansion, stress, and material fatigue, influencing component durability and performance. Understanding and managing thermal loads is critical for designing systems that can withstand dynamic loads, which involve time-dependent mechanical forces such as vibrations, shocks, and cyclic stresses.

Sources of Dynamic Load in Structures

Dynamic loads in structures originate from variable forces such as wind, seismic activity, machinery vibrations, and moving vehicles, causing fluctuating stresses that differ from constant thermal loads. These sources induce time-dependent forces that can lead to fatigue and structural resonance, impacting stability and integrity. Understanding the nature and magnitude of dynamic load sources is essential for designing resilient structures capable of withstanding fluctuating environmental and operational conditions.

Impact of Thermal Load on Materials

Thermal load induces expansion and contraction in materials, leading to stresses that can cause deformation, micro-cracking, or fatigue over time. High thermal fluctuations accelerate material degradation, weaken structural integrity, and reduce service life compared to dynamic loads that primarily cause mechanical wear. Understanding thermal load effects is crucial for selecting heat-resistant alloys and designing components in aerospace, automotive, and power generation industries.

Effects of Dynamic Load on Structures

Dynamic load impacts structures by inducing vibrations, causing fatigue, and accelerating material degradation, which can compromise structural integrity over time. Unlike thermal load, which primarily results in expansion or contraction, dynamic load generates fluctuating stresses that may lead to cracks, joint loosening, and resonance issues. Proper design and damping mechanisms are essential to mitigate the adverse effects of dynamic loading on bridges, buildings, and mechanical components.

Measurement and Calculation of Thermal Load

Thermal load measurement involves determining heat generation and dissipation in systems through sensors that capture temperature rise and associated heat flux, often using thermocouples and infrared thermography. Calculation of thermal load requires precise energy balance equations integrating heat transfer coefficients, material thermal properties, and operational conditions to predict temperature distribution and thermal stress. Accurate thermal load assessment is critical for optimizing cooling strategies and ensuring system reliability in dynamic environments subjected to variable mechanical and electrical loads.

Methods for Assessing Dynamic Load

Methods for assessing dynamic load include analyzing time-varying forces using computational simulations such as finite element analysis (FEA), which captures transient stresses and impacts on structures. Modal analysis helps identify natural frequencies and mode shapes to predict resonant conditions under dynamic loading. Experimental techniques like strain gauge measurements and vibration testing provide real-time data to validate dynamic load models and ensure structural integrity.

Strategies for Managing Thermal and Dynamic Loads

Effective strategies for managing thermal and dynamic loads involve optimizing material selection and structural design to accommodate temperature fluctuations and mechanical stresses. Advanced thermal insulation and active cooling systems reduce heat-induced deformation, while vibration damping technologies and shock absorbers mitigate dynamic load impacts. Implementing real-time monitoring with sensors and predictive maintenance enhances load management efficiency by detecting anomalies early and adjusting operational parameters accordingly.

Thermal load Infographic

libterm.com

libterm.com