Seam welding is a continuous welding process that joins metal sheets along a seam using rotating wheels to apply pressure and electrical current simultaneously. This technique ensures a strong, leak-proof bond ideal for applications requiring airtight or watertight joints, such as in automotive fuel tanks and metal containers. Discover how seam welding can optimize your manufacturing process by exploring its benefits and applications in the full article.

Table of Comparison

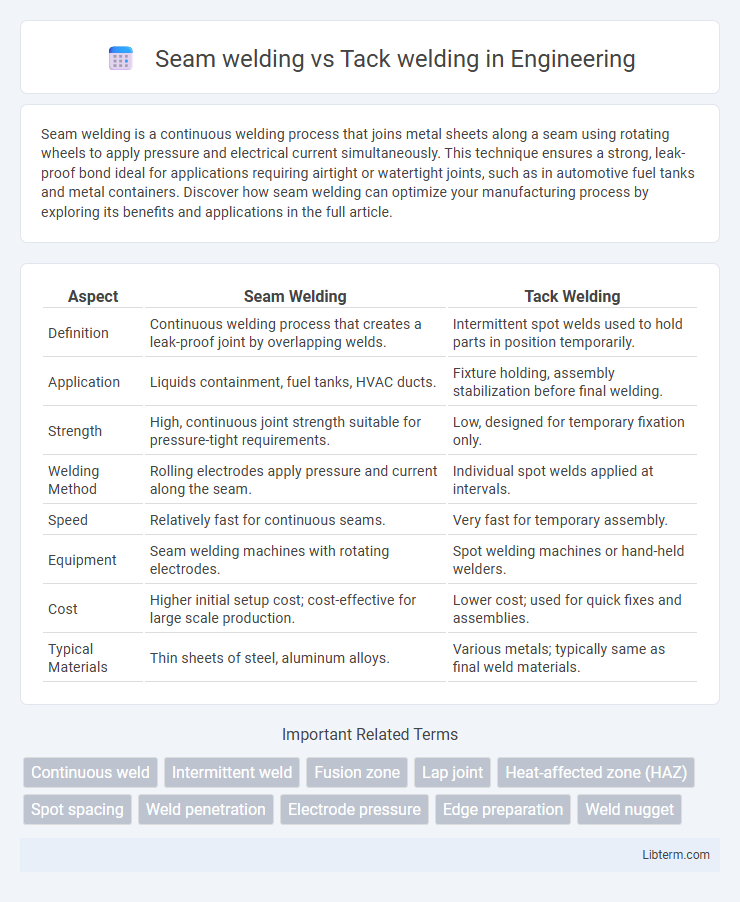

| Aspect | Seam Welding | Tack Welding |

|---|---|---|

| Definition | Continuous welding process that creates a leak-proof joint by overlapping welds. | Intermittent spot welds used to hold parts in position temporarily. |

| Application | Liquids containment, fuel tanks, HVAC ducts. | Fixture holding, assembly stabilization before final welding. |

| Strength | High, continuous joint strength suitable for pressure-tight requirements. | Low, designed for temporary fixation only. |

| Welding Method | Rolling electrodes apply pressure and current along the seam. | Individual spot welds applied at intervals. |

| Speed | Relatively fast for continuous seams. | Very fast for temporary assembly. |

| Equipment | Seam welding machines with rotating electrodes. | Spot welding machines or hand-held welders. |

| Cost | Higher initial setup cost; cost-effective for large scale production. | Lower cost; used for quick fixes and assemblies. |

| Typical Materials | Thin sheets of steel, aluminum alloys. | Various metals; typically same as final weld materials. |

Introduction to Seam Welding and Tack Welding

Seam welding is a continuous welding process that uses rotating wheel electrodes to create a strong, leak-tight joint, mainly applied in manufacturing industries requiring durable metal seams like automotive and packaging. Tack welding involves short, intermittent welds used to temporarily hold components in place before performing a full weld, providing alignment and minimizing distortion. Both techniques play critical roles in metal fabrication, with seam welding ensuring continuous strength and tack welding facilitating precise assembly.

Key Differences Between Seam and Tack Welding

Seam welding creates continuous, leak-tight joints ideal for producing airtight or watertight seals in applications such as fuel tanks and radiators, while tack welding involves short, intermittent welds used primarily to hold components in place before final welding. Seam welding employs continuous current and specific electrode wheels to produce uniform, strong welds along a seam, contrasting with tack welding's brief, spot welds that require minimal heat input. The key differences lie in the weld type, purpose, and application scope--seam welding ensures structural integrity for pressure containment, whereas tack welding serves as temporary fixation to maintain alignment during assembly.

Applications of Seam Welding

Seam welding is extensively used in manufacturing industries that require airtight or watertight joints, such as automotive fuel tanks, metal drums, and HVAC ducts, where continuous, leak-proof seams are critical. It is ideal for joining sheet metals in mass production settings, ensuring consistent strength and aesthetics in products like radiators and industrial containers. Tack welding serves primarily as a temporary fixture method to hold parts in position before final welding but does not provide the continuous sealing properties or mechanical strength needed in applications suited for seam welding.

Applications of Tack Welding

Tack welding is primarily used to temporarily hold parts in place during the assembly of metal structures, providing alignment before final welding. It is widely applied in automotive manufacturing, construction, and shipbuilding to secure components such as frames, panels, and pipes quickly and accurately. Unlike seam welding, which creates continuous joints for airtight or watertight seals, tack welding offers flexibility for adjustments and is ideal for situations requiring intermittent welds to control distortion.

Strength and Durability Comparison

Seam welding creates continuous, uniform welds that provide superior strength and enhanced durability by ensuring consistent metal fusion along the joint. Tack welding offers temporary, localized weld points mainly for alignment, resulting in lower overall joint strength and reduced resistance to fatigue and stress. For applications requiring long-term structural integrity, seam welding is the preferred method due to its ability to produce robust, enduring connections.

Process and Technique Overview

Seam welding uses continuous pressure and electric current to create a long, uniform weld along overlapping metal surfaces, ideal for producing airtight or watertight joints in sheet metals. Tack welding involves applying small, intermittent welds to temporarily hold components in position before final welding, ensuring alignment and preventing distortion during assembly. The primary difference lies in seamless, continuous bonding in seam welding versus discrete, temporary weld spots in tack welding.

Advantages of Seam Welding

Seam welding offers continuous, airtight joints that enhance structural integrity and prevent leakage, making it ideal for applications requiring strength and durability such as fuel tanks and metal drums. It provides consistent quality with minimal distortion compared to tack welding, which only creates intermittent weld points and may require additional finishing. The automated nature of seam welding improves production efficiency, reduces labor costs, and ensures uniform welds critical for high-volume manufacturing processes.

Advantages of Tack Welding

Tack welding offers precise control and faster setup, reducing distortion and improving alignment before final welding. It requires less heat input, minimizing the risk of warping sensitive materials. This technique is ideal for temporarily securing components, enhancing overall fabrication efficiency and accuracy.

Choosing the Right Welding Method

Seam welding creates continuous, airtight joints ideal for metal containers and automotive panels, while tack welding offers quick, temporary spots to hold parts in place before final welding. Selecting the right method depends on project requirements such as strength, production speed, and joint type; seam welding excels in durability and leak prevention, whereas tack welding provides flexibility during assembly. Understanding material thickness, weld length, and application purpose ensures efficient welding process selection for optimal structural integrity and cost-effectiveness.

Conclusion: Seam Welding vs Tack Welding

Seam welding provides continuous, airtight joints ideal for applications requiring strong, durable seals, whereas tack welding creates temporary, intermittent welds mainly used for positioning and alignment before final welding. Choosing seam welding enhances structural integrity and prevents leaks, while tack welding offers flexibility and speed during assembly. The decision depends on whether permanent strength or temporary fixture is the priority in the welding process.

Seam welding Infographic

libterm.com

libterm.com