Slant cutting is a precise sewing technique used to create angled edges on fabric, enhancing garment shapes and improving fit. This method helps reduce bulk and adds a professional finish to your sewing projects. Explore the rest of the article to master slant cutting and elevate your tailoring skills.

Table of Comparison

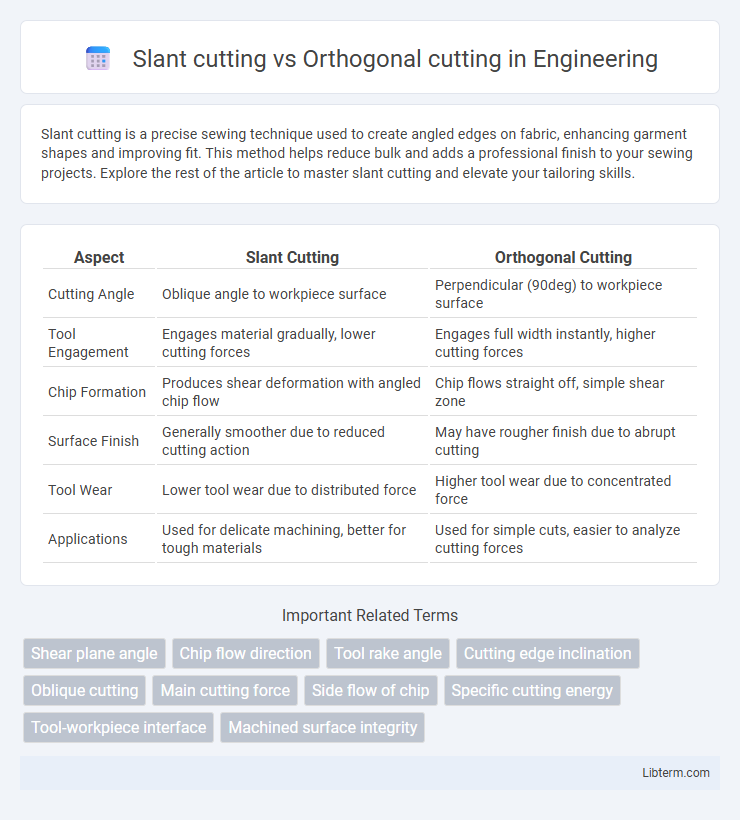

| Aspect | Slant Cutting | Orthogonal Cutting |

|---|---|---|

| Cutting Angle | Oblique angle to workpiece surface | Perpendicular (90deg) to workpiece surface |

| Tool Engagement | Engages material gradually, lower cutting forces | Engages full width instantly, higher cutting forces |

| Chip Formation | Produces shear deformation with angled chip flow | Chip flows straight off, simple shear zone |

| Surface Finish | Generally smoother due to reduced cutting action | May have rougher finish due to abrupt cutting |

| Tool Wear | Lower tool wear due to distributed force | Higher tool wear due to concentrated force |

| Applications | Used for delicate machining, better for tough materials | Used for simple cuts, easier to analyze cutting forces |

Introduction to Cutting Processes

Slant cutting involves machining at an angle to the workpiece surface, enhancing chip flow and reducing cutting forces, while orthogonal cutting occurs with the cutting edge perpendicular to the workpiece, producing simpler shear deformation. Orthogonal cutting is fundamental in metal removal processes, serving as a basis for understanding chip formation, tool wear, and surface finish. Slant cutting improves tool life and surface quality by distributing heat and stress more evenly across the cutting edge.

Understanding Orthogonal Cutting

Orthogonal cutting involves a straight, perpendicular cutting edge relative to the workpiece surface, resulting in a simpler chip formation and more predictable shear plane geometry. This cutting method allows for easier analysis of forces, temperatures, and tool wear, making it ideal for theoretical and experimental studies in machining mechanics. Understanding orthogonal cutting provides essential insights into chip thickness, cutting forces, and material deformation, which are critical for optimizing tool design and machining parameters.

Defining Slant Cutting

Slant cutting refers to the machining process where the cutting tool engages the workpiece at an angle other than 90 degrees, resulting in an angled chip flow and altered cutting forces compared to orthogonal cutting. This method influences the shear plane angle, chip morphology, and tool wear, often improving surface finish and reducing cutting forces in specific applications. Understanding slant cutting mechanics is essential for optimizing tool geometry and machining parameters in industries requiring precision material removal.

Key Principles of Machining Angles

Slant cutting involves machining at an angled approach relative to the workpiece, optimizing chip removal and reducing cutting forces by distributing the load over a longer cutting edge. Orthogonal cutting occurs with the cutting edge perpendicular to the cutting velocity, offering simpler force analysis and predictable chip formation. Key principles include the influence of cutting angle on tool wear, surface finish, and thermal distribution during machining processes.

Differences Between Orthogonal and Slant Cutting

Orthogonal cutting involves a cutting edge perpendicular to the cutting velocity vector, resulting in simpler chip formation and easier force analysis, while slant cutting features an oblique cutting edge creating a shearing action that produces helical chips and reduces cutting forces. The chip flow direction in orthogonal cutting is normal to the cutting edge, whereas in slant cutting it occurs at an angle, impacting surface finish and tool wear. Orthogonal cutting is commonly used for basic machining operations, but slant cutting provides better tool life and smoother surfaces in complex manufacturing scenarios.

Tool Geometry in Both Cutting Methods

Slant cutting features a tool with an angled cutting edge that engages the chip progressively, reducing cutting forces and improving surface finish by distributing tool wear more evenly. Orthogonal cutting employs a tool with a cutting edge perpendicular to the cutting velocity, resulting in a simpler tool geometry but higher instantaneous cutting forces and more concentrated wear. The geometry of slant cutting tools, often including a larger rake angle and inclined edge, enables better shear plane formation compared to the straight edge and neutral rake typically used in orthogonal cutting.

Chip Formation Mechanisms

Slant cutting produces a shearing action resulting in thinner, curled chips due to the angled cutting edge interacting with the material, which reduces cutting force and improves surface finish. Orthogonal cutting involves a perpendicular cutting edge causing more uniform, thicker chips formed by a dominant shear plane mechanism, leading to higher cutting forces. Chip formation in slant cutting enhances chip flow control, while orthogonal cutting emphasizes predictable material removal and chip segmentation.

Surface Finish and Quality Comparison

Slant cutting typically produces a smoother surface finish due to the gradual engagement of the cutting edge, reducing tool marks and minimizing surface roughness compared to orthogonal cutting. Orthogonal cutting often results in a more pronounced surface texture and higher likelihood of built-up edge formation, which can deteriorate surface quality. The improved surface integrity in slant cutting enhances component durability and reduces the need for secondary finishing operations.

Applications of Each Cutting Technique

Slant cutting is primarily used in woodworking and metalworking for angled cuts that require precise bevels and smooth finishes, ideal for decorative edges and joinery. Orthogonal cutting is common in machining processes like turning and milling, where perpendicular tool engagement with the material ensures high precision and efficient chip removal. The choice between slant and orthogonal cutting impacts surface quality, tool wear, and cutting force management in manufacturing applications.

Advantages and Limitations of Slant vs Orthogonal Cutting

Slant cutting offers advantages such as reduced cutting force, smoother chip flow, and lower tool wear compared to orthogonal cutting, making it suitable for machining materials with higher ductility. However, slant cutting can lead to increased cutting tool complexity and requires precise tool geometry control, which may raise manufacturing costs. Orthogonal cutting provides simpler analysis and stable cutting conditions but often results in higher forces and increased heat generation, limiting its effectiveness with tougher materials.

Slant cutting Infographic

libterm.com

libterm.com