Anodizing enhances the durability and corrosion resistance of metal surfaces by forming a protective oxide layer through an electrolytic process. This treatment not only improves the aesthetic appeal but also increases the lifespan of aluminum and other metals used in various industries. Explore the article to discover how anodizing can benefit your metal projects and applications.

Table of Comparison

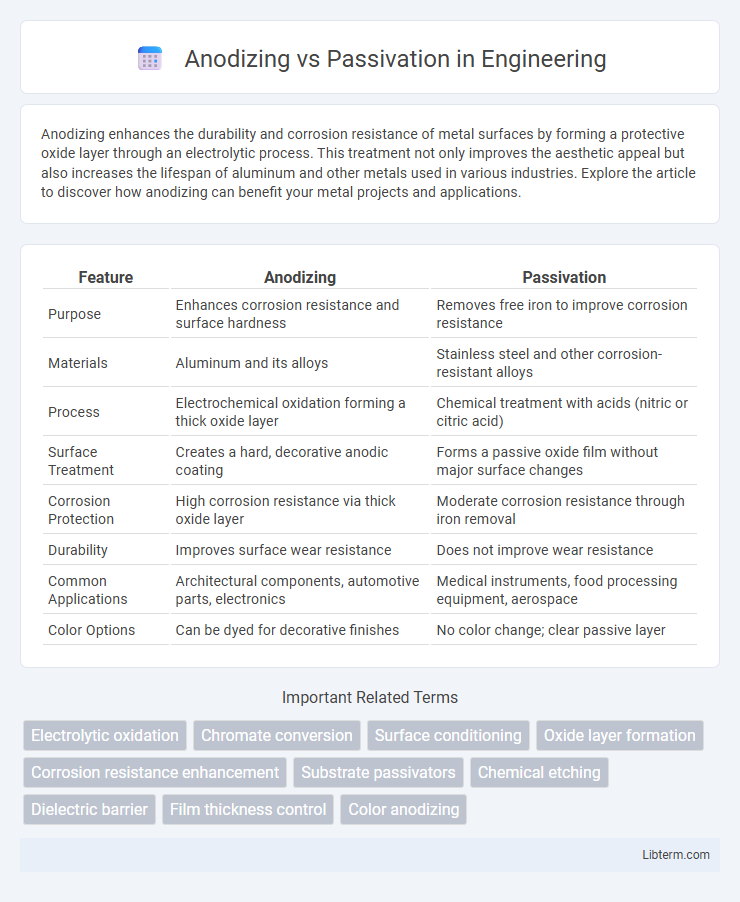

| Feature | Anodizing | Passivation |

|---|---|---|

| Purpose | Enhances corrosion resistance and surface hardness | Removes free iron to improve corrosion resistance |

| Materials | Aluminum and its alloys | Stainless steel and other corrosion-resistant alloys |

| Process | Electrochemical oxidation forming a thick oxide layer | Chemical treatment with acids (nitric or citric acid) |

| Surface Treatment | Creates a hard, decorative anodic coating | Forms a passive oxide film without major surface changes |

| Corrosion Protection | High corrosion resistance via thick oxide layer | Moderate corrosion resistance through iron removal |

| Durability | Improves surface wear resistance | Does not improve wear resistance |

| Common Applications | Architectural components, automotive parts, electronics | Medical instruments, food processing equipment, aerospace |

| Color Options | Can be dyed for decorative finishes | No color change; clear passive layer |

Introduction to Metal Surface Treatments

Anodizing and passivation are essential metal surface treatments enhancing corrosion resistance and durability of aluminum and stainless steel, respectively. Anodizing creates a thick oxide layer through electrochemical processes, improving wear resistance and dye absorption. Passivation chemically removes free iron from stainless steel surfaces, forming a protective chromium-rich oxide layer that prevents rust and contaminants.

What is Anodizing?

Anodizing is an electrochemical process that enhances the natural oxide layer on metals such as aluminum, titanium, and magnesium to improve corrosion resistance, surface hardness, and aesthetic appearance. This controlled oxidation creates a durable, porous oxide layer that can also be dyed in various colors for functional or decorative purposes. Anodizing significantly increases surface durability compared to untreated metal, making it ideal for aerospace, automotive, and architectural applications.

What is Passivation?

Passivation is a chemical treatment process that enhances the corrosion resistance of stainless steel by creating a thin, inert oxide layer on its surface. This oxide layer prevents oxidation and rust formation by blocking exposure to moisture and contaminants. Unlike anodizing, which builds a thicker oxide coating on aluminum, passivation primarily cleans and stabilizes the natural oxide layer on metals such as stainless steel.

Comparison: Anodizing vs Passivation

Anodizing creates a thick, durable oxide layer on aluminum surfaces, enhancing corrosion resistance, wear resistance, and aesthetic appeal through controlled electrochemical processes. Passivation primarily involves treating stainless steel with acid solutions to remove contaminants and form a thin, protective chromium oxide layer that improves corrosion resistance without altering surface dimensions. While anodizing modifies the metal surface by thickening the oxide layer for greater protection and color options, passivation emphasizes chemical cleansing and natural oxide film enhancement to prevent rust and contamination.

Types of Metals Suitable for Each Process

Anodizing is primarily suitable for aluminum, titanium, and magnesium alloys, enhancing their corrosion resistance and surface hardness through controlled oxide layer formation. Passivation is commonly applied to stainless steel and other ferrous metals, promoting the formation of a thin, protective oxide layer that prevents rust and corrosion. Both processes improve durability, but the choice depends on the metal type and desired surface properties.

Key Benefits of Anodizing

Anodizing enhances aluminum surfaces by creating a durable oxide layer that improves corrosion resistance, wear resistance, and surface hardness. This electrochemical process also allows for better paint adhesion and provides a decorative finish with various color options. Compared to passivation, anodizing offers superior protection against environmental factors and increased longevity for aluminum components.

Key Benefits of Passivation

Passivation enhances corrosion resistance by creating a stable, inert oxide layer on stainless steel surfaces, significantly reducing the risk of oxidation and rust. It improves the longevity and durability of metal components in harsh environments by removing free iron and other contaminants that can cause surface degradation. This chemical treatment maintains the metal's aesthetic appeal and structural integrity, making it essential for industries requiring clean, high-performance stainless steel parts.

Applications in Industry

Anodizing enhances corrosion resistance and surface hardness for aluminum parts used in aerospace, automotive, and electronics industries by creating a durable oxide layer. Passivation is crucial for stainless steel components in chemical processing, food production, and medical devices, improving resistance to rust and contamination through a protective oxide film. Both treatments extend the lifespan and performance of metal products by optimizing surface properties specific to industrial application needs.

Cost and Maintenance Differences

Anodizing typically incurs higher costs due to its complex electrochemical process that enhances aluminum's surface hardness and corrosion resistance, resulting in longer-lasting protection with minimal maintenance. Passivation, usually applied to stainless steel, is more cost-effective as it involves a simpler chemical treatment to remove free iron and improve corrosion resistance, but may require more frequent inspections and upkeep to maintain effectiveness. Maintenance for anodized surfaces is generally lower, involving basic cleaning, whereas passivated surfaces demand regular monitoring to prevent oxidation and sustain protective layers.

Choosing the Right Process for Your Needs

Anodizing creates a durable oxide layer on aluminum, enhancing corrosion resistance and surface hardness, making it ideal for decorative and structural applications. Passivation chemically removes free iron from stainless steel surfaces, improving corrosion resistance without altering the metal's appearance, suitable for medical and food-grade equipment. Selecting the right process depends on the metal type, desired surface properties, and specific environmental conditions of the application.

Anodizing Infographic

libterm.com

libterm.com