Loose fit clothing offers exceptional comfort and freedom of movement, making it ideal for everyday wear and active lifestyles. Its relaxed silhouette can also enhance breathability and reduce irritation on the skin. Explore the rest of the article to discover how incorporating loose fit styles can transform your wardrobe and elevate your comfort.

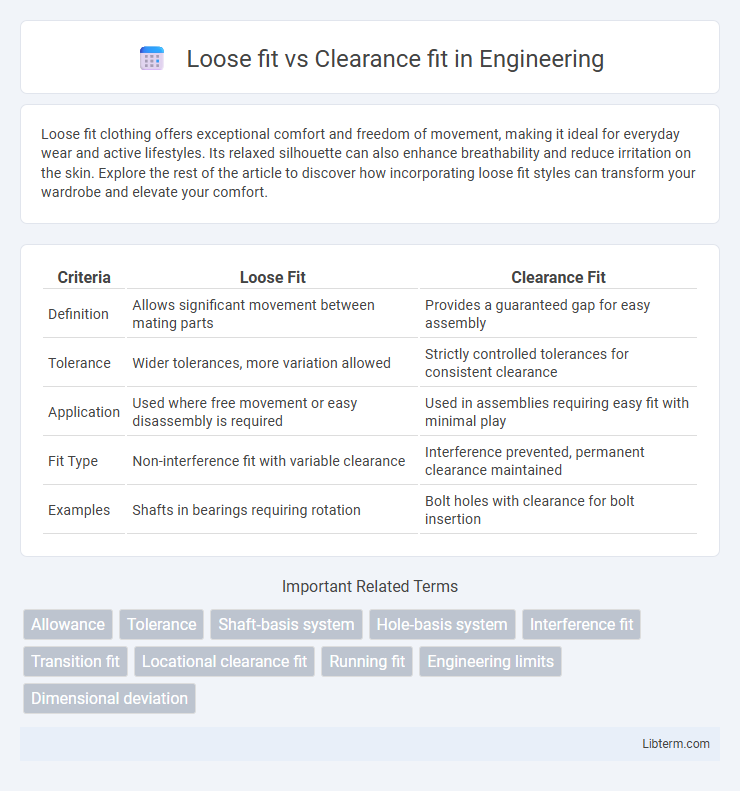

Table of Comparison

| Criteria | Loose Fit | Clearance Fit |

|---|---|---|

| Definition | Allows significant movement between mating parts | Provides a guaranteed gap for easy assembly |

| Tolerance | Wider tolerances, more variation allowed | Strictly controlled tolerances for consistent clearance |

| Application | Used where free movement or easy disassembly is required | Used in assemblies requiring easy fit with minimal play |

| Fit Type | Non-interference fit with variable clearance | Interference prevented, permanent clearance maintained |

| Examples | Shafts in bearings requiring rotation | Bolt holes with clearance for bolt insertion |

Introduction to Fit Types in Engineering

Loose fit provides ample space between mating parts to allow easy assembly and movement, commonly used where precision alignment is not critical. Clearance fit ensures a guaranteed gap, preventing interference and facilitating smooth operation without excessive looseness, essential in rotating or sliding components. Both fit types influence mechanical performance, tolerance design, and assembly methods in engineering applications.

Understanding Loose Fit

Loose fit allows for greater movement and tolerance between mating parts, making it ideal in applications where ease of assembly and disassembly is crucial, such as in automotive or machinery components. The clearance between parts in a loose fit typically exceeds the maximum allowance, preventing interference and reducing the risk of wear or damage during operation. Understanding loose fit involves analyzing dimensional tolerances and application requirements to ensure reliable performance without compromising mechanical function.

Defining Clearance Fit

Clearance fit ensures a space or gap between mating parts, allowing free movement and easy assembly, commonly used in mechanical engineering for shafts and holes requiring smooth operation. This fit type is characterized by a positive allowance, where the hole diameter always exceeds the shaft diameter, preventing interference and facilitating maintenance. Unlike loose fit, which may have variable gaps, clearance fit specifications provide precise minimum clearances to guarantee consistent performance in applications like bearing housings and gear assemblies.

Key Differences Between Loose Fit and Clearance Fit

Loose fit features intentional excess space between mating parts to allow easy assembly and movement, often used where flexibility or thermal expansion is needed. Clearance fit specifies a precise gap ensuring parts move freely without binding, critical in applications demanding reliable operation and minimal friction. The key difference lies in the control of tolerances: loose fit prioritizes ease of assembly, while clearance fit emphasizes predictable, functional space.

Applications of Loose Fit

Loose fit applications are ideal for components requiring easy assembly and disassembly, such as in machinery with frequent maintenance or adjustment needs. This fit type ensures sufficient clearance to accommodate thermal expansion, misalignment, or shaft rotation without interference, commonly used in bearings, pulleys, and gear assemblies. Engineering designs prioritize loose fit when parts must move freely or when speed of installation and removal outweigh precision alignment.

Common Uses of Clearance Fit

Clearance fit is commonly used in applications where easy assembly and disassembly of parts are essential, such as in bearings, gears, and couplings. It ensures there is sufficient space between mating components to allow free movement without interference, preventing wear and facilitating maintenance. This type of fit is ideal for parts that require relative motion or thermal expansion accommodation in machinery and automotive assemblies.

Advantages and Disadvantages of Loose Fit

Loose fit offers easier assembly and better accommodation of dimensional variations, reducing the risk of jamming or damage during installation, which is advantageous in applications requiring frequent disassembly or thermal expansion. However, it can result in increased vibration, noise, and reduced load-carrying capacity compared to clearance fit, potentially leading to premature wear or misalignment in precision machinery. The trade-off between ease of assembly and mechanical stability makes loose fit suitable for non-critical or flexible tolerance applications but less ideal for high-precision or high-load environments.

Pros and Cons of Clearance Fit

Clearance fit provides ease of assembly and accommodates thermal expansion, reducing the risk of parts seizing during operation. It may, however, result in increased vibration, wear, and reduced precision due to the intentional gap between mating components. Optimal clearance fit design balances sufficient movement tolerance with maintaining functional stability in mechanical systems.

Factors Influencing Fit Selection

Factors influencing fit selection between loose fit and clearance fit include the intended application, load conditions, and manufacturing tolerances. Loose fits are preferred for easy assembly and disassembly without precise alignment, accommodating thermal expansion and vibration, while clearance fits ensure relative movement with controlled gaps to prevent interference. Material properties, operating environment, and the need for lubrication also play critical roles in determining the optimal fit type for reliable performance.

Choosing the Right Fit for Your Project

Choosing the right fit for your project depends on the functional requirements and tolerances needed. Loose fit provides more space between parts, allowing easy assembly and movement but may sacrifice precision, ideal for applications with thermal expansion or minor misalignments. Clearance fit ensures parts slide or fit easily without interference, maintaining performance in mechanical assemblies where controlled play is essential for smooth operation and longevity.

Loose fit Infographic

libterm.com

libterm.com