Cyclic load refers to the repeated application of stress or strain on a material or structure, often leading to fatigue and eventual failure over time. Understanding the effects of cyclic loading is essential for designing durable and reliable components in engineering and construction. Discover how cyclic load impacts materials and how you can mitigate its risks by reading the rest of this article.

Table of Comparison

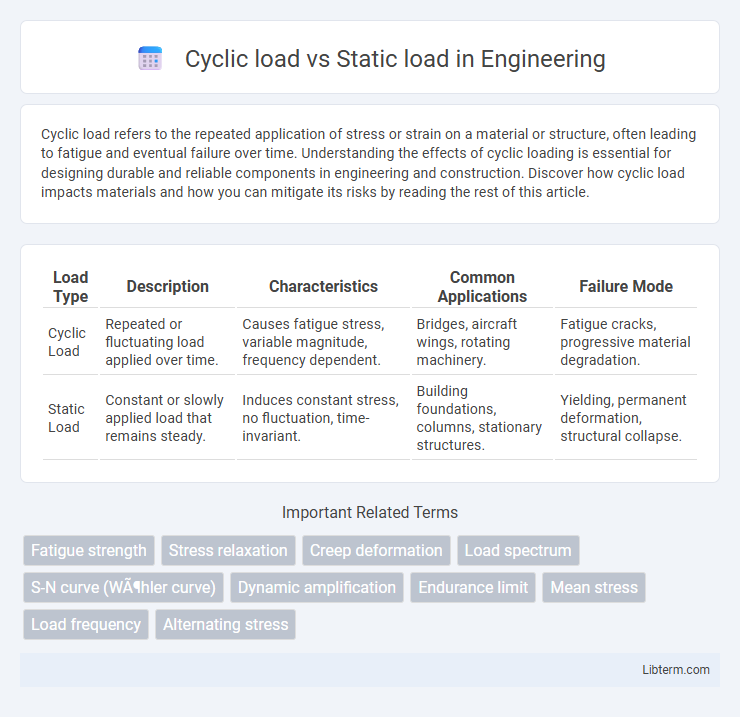

| Load Type | Description | Characteristics | Common Applications | Failure Mode |

|---|---|---|---|---|

| Cyclic Load | Repeated or fluctuating load applied over time. | Causes fatigue stress, variable magnitude, frequency dependent. | Bridges, aircraft wings, rotating machinery. | Fatigue cracks, progressive material degradation. |

| Static Load | Constant or slowly applied load that remains steady. | Induces constant stress, no fluctuation, time-invariant. | Building foundations, columns, stationary structures. | Yielding, permanent deformation, structural collapse. |

Introduction to Cyclic Load and Static Load

Cyclic load refers to the repeated application of stress or force on a material or structure over time, causing fluctuations that can lead to fatigue and eventual failure. Static load involves a constant or slowly applied force that remains steady without significant variation throughout the testing or usage period. Understanding the behaviors of materials under cyclic and static loads is critical in engineering fields like mechanical, civil, and aerospace engineering to ensure durability and safety.

Definitions and Fundamental Concepts

Cyclic load refers to the repeated application of stress or force on a material or structure, causing fluctuating or variable loads over time, which can lead to fatigue and eventual failure. Static load denotes a constant or slowly applied force that remains steady without significant variation, primarily causing deformation or yielding. Understanding these load types is essential for assessing material durability and structural integrity in engineering design and analysis.

Key Differences Between Cyclic and Static Loads

Cyclic load involves repeated or fluctuating forces that cause stress variations over time, often leading to fatigue failure in materials, whereas static load applies a constant force in a fixed position without significant change. Cyclic loading typically demands materials with high fatigue resistance and durability under variable stresses, while static loading primarily requires strength and stability under sustained pressure. Understanding these differences is crucial in designing structures to withstand dynamic stresses and prevent unexpected failures.

Material Behavior Under Cyclic Loading

Material behavior under cyclic loading demonstrates distinct fatigue characteristics compared to static load conditions, where stress is applied once or held constant. Cyclic loading induces microstructural changes such as crack initiation and propagation, significantly reducing the material's fatigue life due to repeated stress fluctuations. Understanding S-N curves (stress versus number of cycles) is essential for predicting failure in materials subject to cyclic stresses, contrasting with static load evaluations that focus on yielding or ultimate tensile strength.

Material Response to Static Loading

Material response to static loading involves deformation and stress distribution that remain constant over time, allowing for predictable elastic and plastic behavior under sustained forces. Unlike cyclic loading, static loads cause gradual material strain without fatigue, affecting properties such as yield strength and elongation in metals or creep resistance in polymers. Understanding static load response is crucial for designing structures that require long-term stability under steady forces.

Fatigue Failure in Cyclic Loading

Cyclic load induces repetitive stress variations that cause microstructural changes, accelerating fatigue failure through crack initiation and propagation over time. Unlike static load, which subjects materials to constant stress potentially leading to immediate deformation or fracture, cyclic loading significantly reduces a component's fatigue life due to accumulated damage. Understanding the stress amplitude and mean stress in cyclic loading is critical for predicting fatigue life and preventing catastrophic failure in engineering materials.

Structural Applications: Cyclic vs Static Loads

Cyclic loads involve repeated or fluctuating forces that induce stress variations, leading to fatigue and potential failure in structural components over time. Static loads apply constant or slowly varying forces, causing deformation without significant stress fluctuations, making them critical for evaluating ultimate strength and stability. Engineers must analyze both load types in structural applications to ensure durability, safety, and compliance with design codes like ASCE 7 and Eurocode.

Testing Methods for Cyclic and Static Loads

Testing methods for cyclic loads typically involve fatigue testing machines that apply repeated stress cycles to evaluate material durability and predict lifespan under fluctuating forces. Static load testing uses universal testing machines to apply a constant force or displacement, measuring deformation and ultimate strength without time-dependent stress variation. Both methods require precise instrumentation to capture load, strain, and displacement data, ensuring accurate assessment of mechanical properties under dynamic and static conditions.

Design Considerations in Engineering

Design considerations for cyclic load involve analyzing fatigue life, stress concentration, and material endurance limits to prevent failure from repeated stress variations. Static load design emphasizes ultimate strength, elastic deformation limits, and safety factors to ensure structural stability under constant or slowly applied forces. Engineers prioritize fatigue analysis under cyclic loads while focusing on yield strength and maximum load capacity in static load scenarios for optimal performance.

Summary and Practical Implications

Cyclic load involves repetitive application of force leading to material fatigue, whereas static load applies a constant force causing deformation without fatigue accumulation. Understanding the differences impacts structural design choices, emphasizing fatigue-resistant materials for cyclic loads and strength-focused materials for static loads. In practical engineering, accounting for cyclic load enhances safety in components like bridges and aircraft, while static load considerations dominate in foundations and stationary structures.

Cyclic load Infographic

libterm.com

libterm.com