Welding is a critical process in manufacturing and construction that joins materials, typically metals or thermoplastics, through high heat and pressure. Mastering different welding techniques can enhance the strength and durability of your projects while ensuring safety and precision. Explore the full article to discover essential tips and methods to improve your welding skills.

Table of Comparison

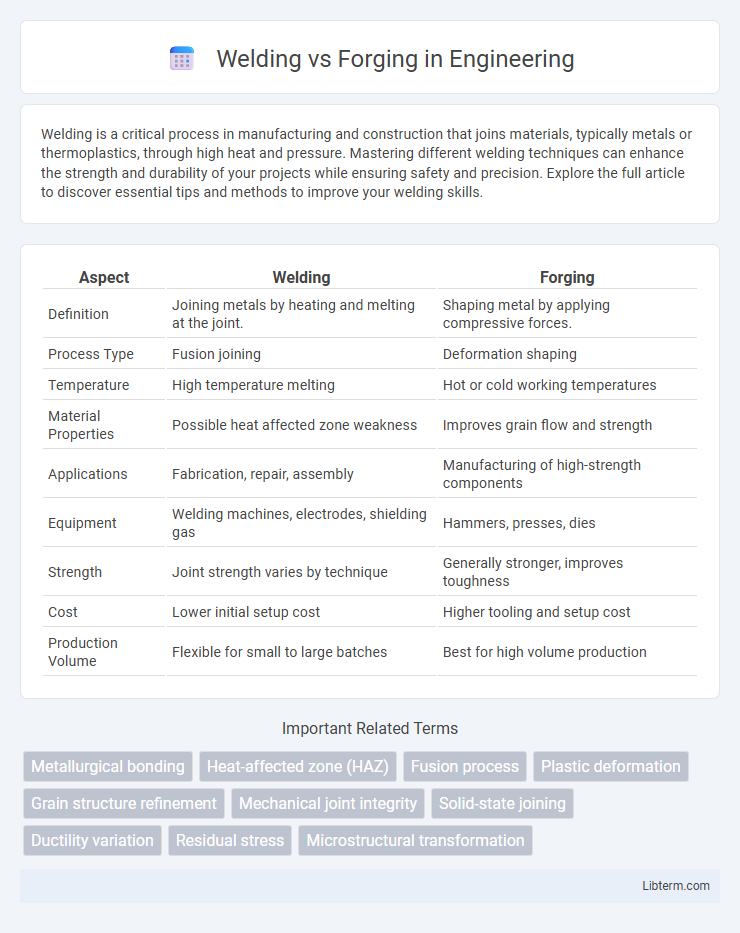

| Aspect | Welding | Forging |

|---|---|---|

| Definition | Joining metals by heating and melting at the joint. | Shaping metal by applying compressive forces. |

| Process Type | Fusion joining | Deformation shaping |

| Temperature | High temperature melting | Hot or cold working temperatures |

| Material Properties | Possible heat affected zone weakness | Improves grain flow and strength |

| Applications | Fabrication, repair, assembly | Manufacturing of high-strength components |

| Equipment | Welding machines, electrodes, shielding gas | Hammers, presses, dies |

| Strength | Joint strength varies by technique | Generally stronger, improves toughness |

| Cost | Lower initial setup cost | Higher tooling and setup cost |

| Production Volume | Flexible for small to large batches | Best for high volume production |

Introduction to Welding and Forging

Welding is a fabrication process that joins materials, typically metals or thermoplastics, by causing coalescence through high heat, pressure, or both, resulting in a permanent bond. Forging involves shaping metal using compressive forces, often utilizing a hammer or press, to improve strength and structural integrity by refining the grain flow. Both techniques are vital in manufacturing, with welding focusing on joining components and forging emphasizing material enhancement and durability.

Fundamental Differences Between Welding and Forging

Welding joins metals by melting and fusing them using heat or pressure, creating a joint at the material's surface, while forging reshapes metal through compressive forces without melting, enhancing its internal grain structure. Welding primarily alters the metal's microstructure at the joint, whereas forging improves mechanical properties throughout the entire workpiece by realigning grains for increased strength and toughness. The fundamental distinction lies in welding's fusion of separate parts compared to forging's deformation of a single metal piece to achieve desired shape and durability.

Process Overview: How Welding Works

Welding involves joining two metal pieces by melting their edges and adding a filler material to form a strong joint upon cooling. This process creates a metallurgical bond through localized heating, often using techniques such as arc welding, MIG, or TIG. Unlike forging, which reshapes metal through compression and deformation, welding focuses on fusing materials together to create assemblies or repairs.

Process Overview: How Forging Works

Forging involves shaping metal by applying compressive forces using a hammer or press, typically at high temperatures to enhance material ductility. This process refines the grain structure, improving mechanical properties like strength and toughness compared to welding, where metals are joined by melting and solidification. Forged components exhibit superior fatigue resistance and structural integrity due to the continuous grain flow aligned with the shape of the part.

Material Compatibility in Welding and Forging

Material compatibility in welding requires careful consideration of thermal expansion, melting points, and chemical composition to prevent defects such as cracking and brittleness. Forging allows for joining materials with similar metallurgical properties by plastic deformation at high temperatures, enhancing strength and grain structure without compromising integrity. Welding is more flexible for dissimilar metals but demands precise control to ensure joint reliability, whereas forging excels in uniformity when materials share compatible mechanical characteristics.

Strength and Durability Comparison

Forging produces components with superior strength and durability due to its grain-refinement process, which aligns the metal's internal structure and eliminates porosity. Welding introduces localized heat that may cause residual stresses and potential weak points, reducing overall toughness compared to forged parts. Forged materials consistently outperform welded joints in fatigue resistance and impact strength, making forging the preferred choice for high-stress applications.

Cost Analysis: Welding vs Forging

Welding generally offers lower upfront equipment and labor costs compared to forging, making it cost-effective for small to medium production runs and complex geometries. Forging involves higher initial investment due to the need for specialized dies and presses, but it provides superior material strength and consistency for large-scale manufacturing, reducing long-term expenses. Evaluating the total cost must consider factors such as production volume, material properties, and post-processing requirements to determine the most economical choice between welding and forging.

Application Suitability: Industry Use Cases

Forging is ideal for high-strength components in automotive, aerospace, and heavy machinery industries where durability and fatigue resistance are critical. Welding suits construction, shipbuilding, and pipeline industries that require joining complex assemblies and repairs with flexibility and cost efficiency. Each process aligns with specific application needs, balancing mechanical properties and production scale for optimal performance.

Pros and Cons of Welding and Forging

Welding offers strong, permanent joints ideal for complex shapes but may introduce heat-related distortions and requires skilled labor. Forging produces components with superior strength, durability, and fatigue resistance due to grain refinement, yet it involves higher tooling costs and limited design flexibility. Both methods present trade-offs in cost, mechanical properties, and manufacturing complexity, influencing their suitability for specific industrial applications.

Choosing the Right Method for Your Project

Selecting between welding and forging depends on project requirements such as strength, precision, and material type. Welding offers flexibility for joining complex shapes with localized heat, ideal for repairs and custom assemblies. Forging produces stronger, more durable components by shaping metal under high pressure, preferred for high-stress applications requiring superior structural integrity.

Welding Infographic

libterm.com

libterm.com