Alloy materials combine two or more metals to enhance strength, durability, and resistance to corrosion, making them ideal for various industrial applications. Commonly used alloys include steel, brass, and bronze, each tailored to specific performance requirements in construction, manufacturing, and automotive industries. Discover how different alloy compositions can optimize Your projects by reading the rest of the article.

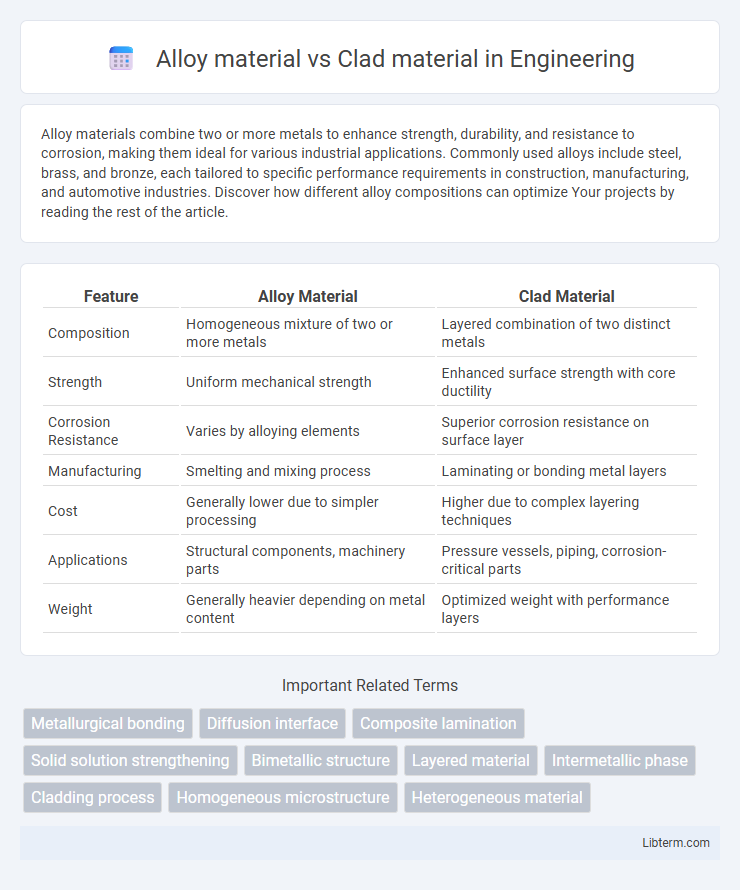

Table of Comparison

| Feature | Alloy Material | Clad Material |

|---|---|---|

| Composition | Homogeneous mixture of two or more metals | Layered combination of two distinct metals |

| Strength | Uniform mechanical strength | Enhanced surface strength with core ductility |

| Corrosion Resistance | Varies by alloying elements | Superior corrosion resistance on surface layer |

| Manufacturing | Smelting and mixing process | Laminating or bonding metal layers |

| Cost | Generally lower due to simpler processing | Higher due to complex layering techniques |

| Applications | Structural components, machinery parts | Pressure vessels, piping, corrosion-critical parts |

| Weight | Generally heavier depending on metal content | Optimized weight with performance layers |

Introduction to Alloy and Clad Materials

Alloy materials consist of metals blended with one or more elements to enhance mechanical properties such as strength, corrosion resistance, and durability. Clad materials feature a core metal bonded with one or more external layers of different metals, combining the core's structural qualities with the surface's specialized properties like corrosion resistance. Both materials are widely used in industries requiring tailored physical and chemical characteristics for applications in aerospace, construction, and marine environments.

Composition and Structure Differences

Alloy materials consist of a homogeneous mixture of two or more metallic elements combined at the atomic level, resulting in uniform properties throughout the material. Clad materials feature a layered structure, where a core metal is bonded with one or more outer metal layers, enhancing surface properties such as corrosion resistance while maintaining the core's mechanical characteristics. The compositional difference lies in alloys having a single-phase composition, whereas clad materials maintain distinct layers of different metals bonded together physically rather than chemically.

Manufacturing Processes Compared

Alloy materials undergo homogenization and heat treatment processes to achieve uniform mechanical properties, optimizing their strength and corrosion resistance. Clad materials combine distinct layers through bonding techniques such as roll bonding, explosive welding, or diffusion bonding, allowing each layer to retain its individual properties for enhanced overall performance. Manufacturing alloys requires precise control of composition and phase transformation, while clad materials focus on interfacial integrity and compatibility between dissimilar metals.

Mechanical Properties and Performance

Alloy materials demonstrate superior mechanical properties such as enhanced tensile strength, hardness, and corrosion resistance due to the combination of metals and controlled microstructure. Clad materials offer the advantage of combining a strong core alloy with a corrosion-resistant outer layer, ensuring excellent performance in harsh environments while maintaining structural integrity. The choice between alloy and clad materials depends on the specific application requirements for durability, mechanical stress, and environmental exposure.

Corrosion Resistance and Durability

Alloy materials offer enhanced corrosion resistance due to their homogeneous composition and controlled elements like chromium and nickel, which form protective oxide layers. Clad materials combine a corrosion-resistant outer layer, such as stainless steel, with a tougher core material, optimizing durability and resistance against environmental factors and mechanical wear. The durability of clad materials often surpasses that of alloys in applications requiring both structural strength and surface protection.

Cost Considerations and Economic Impact

Alloy materials generally incur higher costs due to their complex manufacturing processes and the inclusion of multiple metals to achieve enhanced properties such as strength and corrosion resistance. Clad materials offer a cost-effective alternative by bonding a thin layer of expensive metal onto a more affordable base metal, significantly reducing material expenses while maintaining surface performance. Economic impacts favor clad materials in large-scale applications where budget constraints prioritize cost savings without compromising critical functional characteristics.

Applications in Various Industries

Alloy materials are extensively used in aerospace, automotive, and construction industries due to their enhanced strength, corrosion resistance, and ability to withstand high temperatures. Clad materials find applications in chemical processing, electronics, and marine industries where surface properties like corrosion resistance and conductivity are critical while maintaining the core material's structural integrity. Both materials optimize performance by combining desirable properties tailored to specific industrial requirements.

Environmental Impact and Sustainability

Alloy materials often require energy-intensive mining and smelting processes that generate significant greenhouse gas emissions and toxic waste, impacting ecosystems and water resources. Clad materials, composed of a base metal bonded with a corrosion-resistant layer, generally extend product lifespan and reduce the need for frequent replacements, contributing to resource conservation and waste reduction. Lifecycle assessments highlight clad materials' potential for enhanced sustainability by minimizing raw material extraction and improving recyclability compared to traditional alloys.

Advantages and Limitations of Alloy Materials

Alloy materials offer enhanced mechanical properties such as increased strength, corrosion resistance, and improved durability compared to pure metals, making them ideal for demanding industrial applications. They enable customization of thermal and electrical conductivity, which extends their utility across aerospace, automotive, and construction sectors. Limitations include higher production costs, potential difficulties in recycling, and less uniformity in microstructure compared to clad materials, which may affect performance consistency.

Advantages and Limitations of Clad Materials

Clad materials offer enhanced corrosion resistance and improved mechanical properties by combining the best characteristics of two or more metals, often providing superior performance in harsh environments compared to traditional alloys. They are advantageous in applications requiring both a strong core and a corrosion-resistant surface, such as chemical processing and marine environments, but their complexity can result in higher production costs and challenges in repair or welding. Limitations include potential delamination risks and difficulty in maintaining uniform thickness, which may affect long-term durability and performance.

Alloy material Infographic

libterm.com

libterm.com