Vapor pressure lowering occurs when a non-volatile solute is added to a solvent, reducing the solvent's ability to evaporate and thus decreasing its vapor pressure. This colligative property directly depends on the mole fraction of the solute particles in the solution, impacting processes such as boiling point elevation and freezing point depression. Explore the article to understand how vapor pressure lowering influences various chemical and physical phenomena relevant to your studies.

Table of Comparison

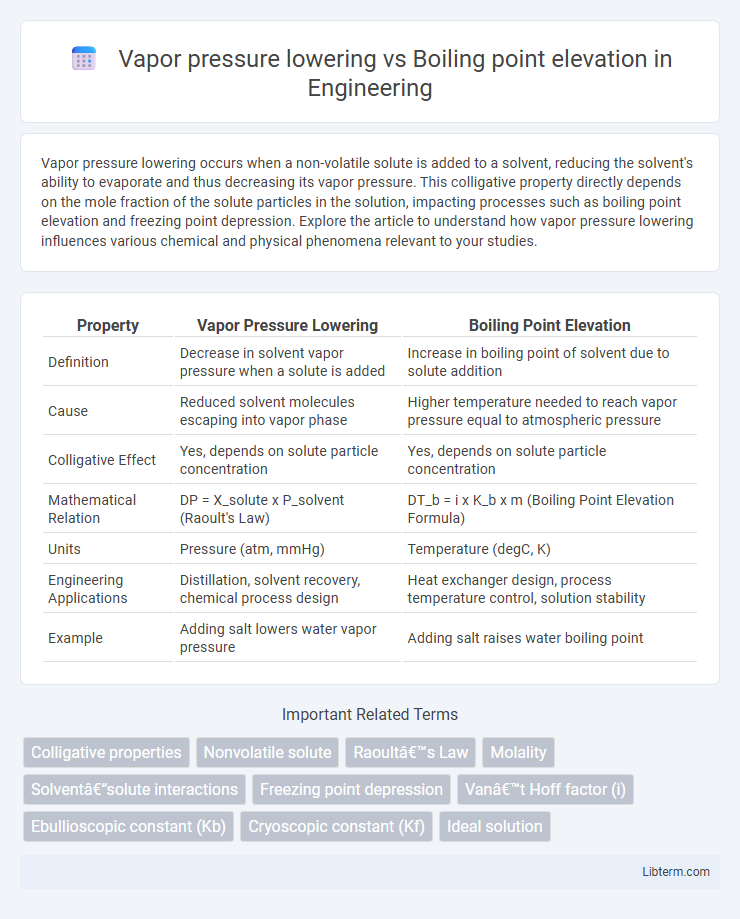

| Property | Vapor Pressure Lowering | Boiling Point Elevation |

|---|---|---|

| Definition | Decrease in solvent vapor pressure when a solute is added | Increase in boiling point of solvent due to solute addition |

| Cause | Reduced solvent molecules escaping into vapor phase | Higher temperature needed to reach vapor pressure equal to atmospheric pressure |

| Colligative Effect | Yes, depends on solute particle concentration | Yes, depends on solute particle concentration |

| Mathematical Relation | DP = X_solute x P_solvent (Raoult's Law) | DT_b = i x K_b x m (Boiling Point Elevation Formula) |

| Units | Pressure (atm, mmHg) | Temperature (degC, K) |

| Engineering Applications | Distillation, solvent recovery, chemical process design | Heat exchanger design, process temperature control, solution stability |

| Example | Adding salt lowers water vapor pressure | Adding salt raises water boiling point |

Introduction to Colligative Properties

Colligative properties depend on the number of solute particles in a solvent rather than their identity, with vapor pressure lowering and boiling point elevation being key examples. Vapor pressure lowering occurs because solute particles reduce the solvent's ability to evaporate, decreasing the vapor pressure above the liquid. Boiling point elevation arises as the solution requires a higher temperature to reach the vapor pressure needed for boiling due to the decreased vapor pressure caused by dissolved solutes.

Understanding Vapor Pressure Lowering

Vapor pressure lowering occurs when a non-volatile solute is dissolved in a solvent, reducing the solvent's tendency to evaporate due to a decrease in the number of solvent molecules at the surface. This colligative property directly influences boiling point elevation, as a lower vapor pressure requires a higher temperature to reach atmospheric pressure. Understanding vapor pressure lowering is essential for applications in solution chemistry, such as calculating molar masses or designing antifreeze solutions.

The Science Behind Boiling Point Elevation

Boiling point elevation occurs because solute particles disrupt the solvent's vapor pressure, requiring higher temperatures to reach atmospheric pressure and boil. The presence of non-volatile solutes lowers the solvent's vapor pressure through Raoult's Law, directly influencing the phase change temperature. This colligative property is quantitatively described by the equation DTb = iKb m, where DTb is the boiling point elevation, i is the van't Hoff factor, Kb is the ebullioscopic constant, and m is the molal concentration of the solute.

Key Differences: Vapor Pressure Lowering vs Boiling Point Elevation

Vapor pressure lowering occurs when a non-volatile solute is added to a solvent, reducing the solvent's vapor pressure due to solute-solvent interactions that hinder solvent molecules from escaping into the vapor phase. Boiling point elevation happens because the solution requires a higher temperature to reach atmospheric pressure since the vapor pressure is lowered, delaying the phase change from liquid to gas. The key difference lies in vapor pressure lowering being a direct colligative effect on vapor pressure, while boiling point elevation is a consequential effect resulting from the decreased vapor pressure.

Molecular Mechanisms Involved

Vapor pressure lowering occurs when solute molecules disrupt the solvent's surface, reducing solvent molecule escape into the vapor phase by decreasing the solvent's escaping tendency. Boiling point elevation results from the lowered vapor pressure requiring a higher temperature to reach atmospheric pressure, driven by solute-solvent interactions that hinder solvent molecule mobility. Both phenomena arise from colligative effects where solute particle presence alters solvent molecular dynamics and energy distribution at the interface.

Real-World Examples and Applications

Vapor pressure lowering occurs when a non-volatile solute is added to a solvent, reducing the solvent's vapor pressure and is commonly observed in seawater, where dissolved salts decrease evaporation rates and influence climate patterns. Boiling point elevation happens as the solute particles disrupt solvent molecules, requiring higher temperatures to reach boiling; a practical example is adding antifreeze (ethylene glycol) to water in car radiators to prevent boiling in hot conditions. Both colligative properties are critical in industrial processes like food preservation, pharmaceuticals, and chemical manufacturing, where controlling phase changes ensures product stability and safety.

Impact of Solute Type and Concentration

Vapor pressure lowering and boiling point elevation are colligative properties that depend on solute concentration rather than solute identity, meaning non-volatile solutes reduce vapor pressure and raise boiling point proportionally to their molal concentration. Electrolytes, which dissociate into ions, cause a greater impact on these properties compared to non-electrolytes due to increased particle number in solution. The extent of vapor pressure lowering and boiling point elevation is directly proportional to the total number of solute particles, making solute dissociation and concentration critical factors.

Experimental Measurement Techniques

Vapor pressure lowering is typically measured using methods such as isoteniscope or static equilibrium cells, which allow precise determination of vapor pressure changes in solutions. Boiling point elevation is experimentally determined by recording the temperature at which a solution's vapor pressure equals atmospheric pressure, often using ebulliometers for accuracy. Both techniques require careful temperature control and calibration to accurately quantify colligative effects in solutions.

Practical Implications in Industry

Vapor pressure lowering is crucial in refrigeration and air conditioning industries where controlling solvent evaporation prevents system inefficiency and environmental damage. Boiling point elevation finds practical use in food processing and chemical manufacturing to enhance heat transfer efficiency and prevent premature boiling during distillation or concentration processes. Both phenomena directly impact the design of industrial processes involving solvents, ensuring safety, energy efficiency, and product quality.

Summary and Comparative Analysis

Vapor pressure lowering occurs when a non-volatile solute reduces the solvent's vapor pressure by disrupting its surface molecules, while boiling point elevation results from the decreased vapor pressure requiring a higher temperature to reach atmospheric pressure. Both colligative properties depend on solute particle concentration rather than chemical identity, proportionally affecting the solvent's phase change behavior. Vapor pressure lowering directly influences volatility, whereas boiling point elevation impacts the temperature needed for phase transition, making them interrelated yet distinct phenomena in solution thermodynamics.

Vapor pressure lowering Infographic

libterm.com

libterm.com