JIT (Just-In-Time) and Kanban are lean manufacturing techniques designed to reduce waste and improve efficiency by delivering materials only as needed in the production process. Kanban uses visual signals to control workflow and inventory levels, ensuring that your operations run smoothly without excess stock. Explore the rest of this article to discover how implementing JIT and Kanban can transform your manufacturing system.

Table of Comparison

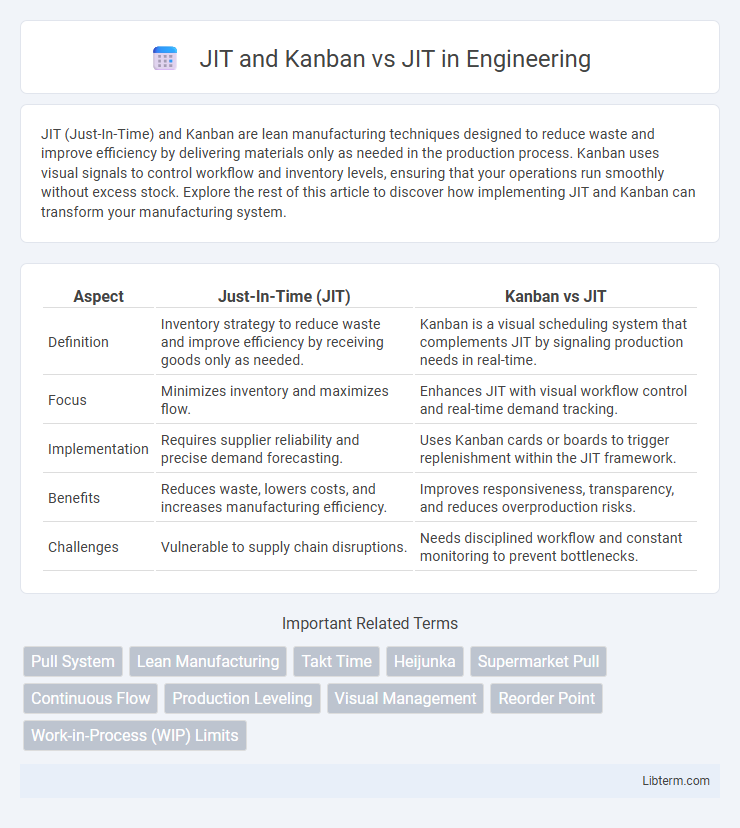

| Aspect | Just-In-Time (JIT) | Kanban vs JIT |

|---|---|---|

| Definition | Inventory strategy to reduce waste and improve efficiency by receiving goods only as needed. | Kanban is a visual scheduling system that complements JIT by signaling production needs in real-time. |

| Focus | Minimizes inventory and maximizes flow. | Enhances JIT with visual workflow control and real-time demand tracking. |

| Implementation | Requires supplier reliability and precise demand forecasting. | Uses Kanban cards or boards to trigger replenishment within the JIT framework. |

| Benefits | Reduces waste, lowers costs, and increases manufacturing efficiency. | Improves responsiveness, transparency, and reduces overproduction risks. |

| Challenges | Vulnerable to supply chain disruptions. | Needs disciplined workflow and constant monitoring to prevent bottlenecks. |

Introduction to JIT and Kanban

Just-In-Time (JIT) is a lean manufacturing methodology that reduces waste by producing only what is needed, when it is needed, improving inventory efficiency and cost savings. Kanban, a visual scheduling system, supports JIT by controlling work-in-progress and signaling demand through cards or electronic boards, enhancing workflow transparency. Both JIT and Kanban aim to optimize production processes, but Kanban specifically facilitates real-time communication and inventory control within the JIT framework.

Overview of Just-In-Time (JIT) Methodology

Just-In-Time (JIT) methodology focuses on reducing inventory costs by receiving goods only as they are needed in the production process, thereby minimizing waste and improving efficiency. Kanban, a scheduling system within the JIT framework, uses visual signals to trigger the movement and production of materials, ensuring smooth workflow and inventory control. Comparing JIT and Kanban highlights JIT as a broader strategy for inventory management, while Kanban serves as a specific tool to implement JIT principles effectively.

Fundamental Principles of Kanban

Kanban is built on fundamental principles such as visualizing workflow, limiting work in progress (WIP), and managing flow to optimize efficiency and reduce waste, contrasting with Just-In-Time (JIT) which primarily focuses on inventory reduction and production timing. Kanban emphasizes continuous delivery and adaptability by utilizing visual boards to monitor task progress and identify bottlenecks in real-time. This approach enhances communication and flexibility, promoting incremental improvements over rigid scheduling typical of JIT systems.

How JIT Streamlines Production

Just-In-Time (JIT) streamlines production by minimizing inventory levels and reducing waste through precise demand forecasting and timely material delivery. Kanban, a visual scheduling system within JIT, enhances workflow by signaling when to replenish stock, preventing overproduction and bottlenecks. Comparing the two, JIT offers a broad production philosophy focused on overall system efficiency, while Kanban acts as a tactical tool to implement JIT principles at the shop floor level.

Key Differences Between JIT and Kanban

Just-In-Time (JIT) is an inventory management strategy that aims to reduce waste by receiving goods only as they are needed in the production process, whereas Kanban is a visual scheduling system used to implement JIT by controlling the flow of materials. The key difference lies in JIT being a broader production methodology focused on efficiency and waste reduction, while Kanban serves as a specific tool or technique to signal work status and inventory levels. JIT emphasizes timing and inventory reduction, whereas Kanban prioritizes workflow transparency and continuous communication between production stages.

Advantages of Using JIT in Manufacturing

Just-In-Time (JIT) manufacturing reduces inventory costs by producing only what is needed when it's needed, minimizing waste and storage expenses. Kanban, a visual scheduling system, supports JIT by signaling production needs, improving workflow and inventory control. Implementing JIT enhances efficiency, accelerates response to market demand, and increases product quality through continuous improvement and streamlined processes.

Benefits of Implementing Kanban Systems

Kanban systems enhance JIT by visualizing workflow stages, enabling real-time inventory control and reducing waste through pull-based production. Implementing Kanban improves lead time, increases flexibility, and optimizes resource allocation without overburdening employees. The system supports continuous improvement, minimizes stockouts, and aligns production closely with actual customer demand.

JIT vs Kanban: Which Is Better for Lean Management?

JIT (Just-In-Time) and Kanban both drive lean management by minimizing waste and optimizing production flow, yet JIT emphasizes synchronized inventory control linked to demand, while Kanban centers on visual workflow management through signal cards. JIT's pull-based approach reduces overproduction but may require precise demand forecasting, whereas Kanban enhances real-time task tracking and flexibility across teams. Choosing between JIT and Kanban depends on organizational needs: JIT suits manufacturing environments where inventory costs dominate, while Kanban excels in dynamic or service-oriented processes prioritizing workflow transparency.

Common Challenges in JIT and Kanban Adoption

Common challenges in JIT and Kanban adoption include demand variability, which complicates precise inventory management and workflow synchronization, leading to potential stockouts or overproduction. Both methodologies require a cultural shift towards continuous improvement and employee empowerment, often hindered by resistance to change and inadequate training. Furthermore, supplier reliability plays a critical role; inconsistent lead times disrupt JIT's tight production schedules and Kanban's signaling system, reducing overall efficiency.

Best Practices for Integrating JIT and Kanban

Integrating JIT and Kanban requires aligning inventory levels with real-time demand signals to minimize waste and enhance flow efficiency in production. Implementing visual Kanban boards alongside JIT principles enables precise pull-based inventory control, reducing lead times and overproduction risks. Consistent monitoring of takt time and continuous communication across teams ensure synchronization between supply and demand, driving lean operations.

JIT and Kanban Infographic

libterm.com

libterm.com