Torsional capacity measures a material or structure's ability to resist twisting forces without failure. Understanding this property is essential for engineers to design safe and efficient components in applications ranging from bridges to automotive parts. Explore the rest of the article to learn how torsional capacity impacts your projects and the methods used to calculate it accurately.

Table of Comparison

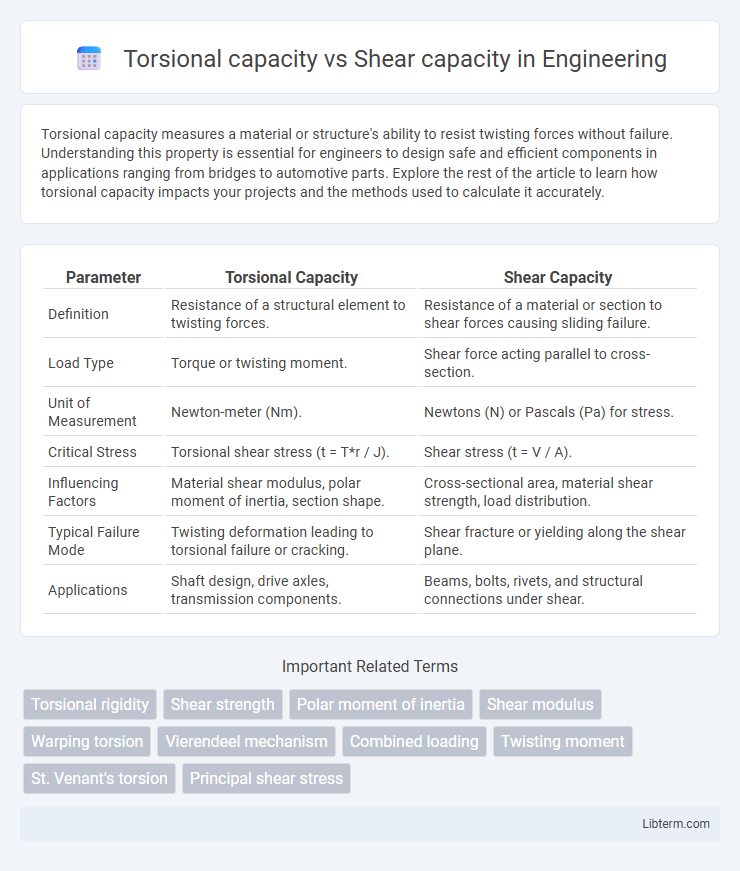

| Parameter | Torsional Capacity | Shear Capacity |

|---|---|---|

| Definition | Resistance of a structural element to twisting forces. | Resistance of a material or section to shear forces causing sliding failure. |

| Load Type | Torque or twisting moment. | Shear force acting parallel to cross-section. |

| Unit of Measurement | Newton-meter (Nm). | Newtons (N) or Pascals (Pa) for stress. |

| Critical Stress | Torsional shear stress (t = T*r / J). | Shear stress (t = V / A). |

| Influencing Factors | Material shear modulus, polar moment of inertia, section shape. | Cross-sectional area, material shear strength, load distribution. |

| Typical Failure Mode | Twisting deformation leading to torsional failure or cracking. | Shear fracture or yielding along the shear plane. |

| Applications | Shaft design, drive axles, transmission components. | Beams, bolts, rivets, and structural connections under shear. |

Understanding Torsional Capacity

Torsional capacity refers to a material or structural element's ability to withstand twisting forces without failure, which is critical in applications like shafts and beams subjected to torque. It depends on factors such as the cross-sectional shape, material properties, and length of the member, with circular sections typically offering higher torsional resistance. Understanding torsional capacity involves analyzing shear stress distribution and ensuring it remains within limits defined by the material's shear strength to prevent structural failure under applied torque.

Defining Shear Capacity

Shear capacity defines the maximum shear force that a structural element can resist without failure, determined by its material strength, cross-sectional area, and geometric properties. Torsional capacity, on the other hand, refers to the ability of a component to withstand twisting forces, influenced by its shape, size, and material stiffness. Understanding shear capacity is crucial for designing safe structures as it prevents sudden shear failures under applied loads.

Key Differences: Torsion vs Shear

Torsional capacity refers to a material's ability to withstand twisting forces causing angular deformation, while shear capacity measures resistance to forces that cause sliding or cutting along a plane. Key differences include the stress distribution, with torsion producing shear stresses over the cross-section in a circular pattern, and shear creating direct shear stresses concentrated along a particular plane. Design considerations for torsion involve polar moment of inertia and circular cross-sections, whereas shear capacity emphasizes shear area and planar force application.

Factors Influencing Torsional Capacity

Torsional capacity depends on material properties, cross-sectional geometry, and boundary conditions, which collectively influence a structure's ability to resist twisting forces. Factors such as shear modulus, shape factor, and the presence of stress concentrators directly impact torsional resistance. Unlike shear capacity, which primarily involves the shear strength of materials, torsional capacity requires consideration of warping effects and torsion-induced stresses in design calculations.

Factors Affecting Shear Capacity

Shear capacity depends heavily on factors such as material strength, cross-sectional shape, and the presence of shear reinforcement, while torsional capacity is influenced by the geometric properties and the distribution of torsional reinforcement. The shear strength of concrete elements is affected by variables such as aggregate size, concrete compressive strength, and shear span-to-depth ratio. Proper detailing of stirrups and transverse reinforcements plays a crucial role in enhancing the shear capacity and preventing premature failures.

Structural Importance of Torsion and Shear

Torsional capacity refers to a structural element's ability to resist twisting forces, while shear capacity defines its resistance to sliding or cutting forces along a plane. Torsion plays a critical role in elements such as beams and shafts subjected to eccentric loads or asymmetrical cross-sections, ensuring structural stability and preventing warping or failure. Shear capacity is vital for maintaining the integrity of beams, columns, and connections under vertical loads, preventing shear cracks and ensuring load transfer efficiency.

Methods for Calculating Torsional Capacity

Methods for calculating torsional capacity rely heavily on determining the resistive moment provided by a structural member's cross-sectional geometry and material properties, such as modulus of rigidity and yield strength. Common approaches include the simplified theory of uniform torsion, the warping torsion theory, and advanced finite element analysis which assess torsional stresses and strains for complex geometries. These methods contrast with shear capacity calculations that focus primarily on the shear area and shear strength to evaluate resistance against shear forces rather than twisting moments.

Evaluating Shear Strength in Structures

Evaluating shear strength in structures involves analyzing the material's ability to resist forces parallel to its cross-section, critical for preventing shear failure in beams and slabs. Torsional capacity, related to resistance against twisting moments, differs as it deals with combined shear stresses distributed over the cross-section's perimeter, requiring specialized design considerations. Understanding the interplay between torsional capacity and shear capacity ensures structural integrity under complex loading conditions, emphasizing accurate assessment of shear strength parameters like shear modulus and shear area.

Design Considerations: Torsion vs Shear

Torsional capacity in structural design addresses a member's ability to resist twisting moments, requiring detailed analysis of shear flow and reinforcement placement, especially in beams and slabs subjected to torque. Shear capacity focuses on resisting forces parallel to the cross-section, necessitating adequate stirrups or shear reinforcement to prevent diagonal tension failure. Design considerations prioritize torsion-reinforced elements with closed stirrups or ties to prevent distortion, while shear design emphasizes shear reinforcement spacing and concrete shear strength for crack control.

Common Failures from Inadequate Torsional or Shear Capacity

Inadequate torsional capacity often leads to cracking and sudden structural failure due to excessive twisting moments in beams and slabs, compromising overall stability. Shear capacity deficiencies typically cause diagonal tension failures or brittle shear cracks near support zones, reducing load-bearing effectiveness. Both conditions increase the risk of progressive collapse, emphasizing the necessity for accurate assessment and reinforcement design to prevent structural hazards.

Torsional capacity Infographic

libterm.com

libterm.com