Martensitic structures exhibit exceptional hardness and strength due to a unique transformation in steel's crystal lattice during rapid cooling. This phase is critical in applications requiring wear resistance and toughness, such as cutting tools and structural components. Explore the full article to understand how martensitic transformation impacts material performance and your design choices.

Table of Comparison

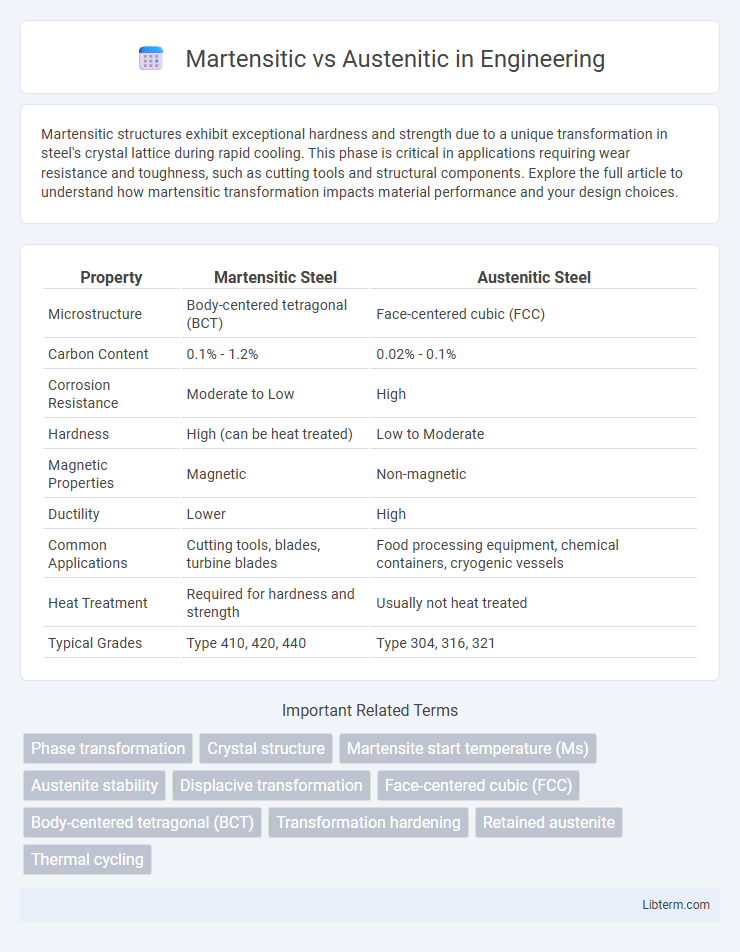

| Property | Martensitic Steel | Austenitic Steel |

|---|---|---|

| Microstructure | Body-centered tetragonal (BCT) | Face-centered cubic (FCC) |

| Carbon Content | 0.1% - 1.2% | 0.02% - 0.1% |

| Corrosion Resistance | Moderate to Low | High |

| Hardness | High (can be heat treated) | Low to Moderate |

| Magnetic Properties | Magnetic | Non-magnetic |

| Ductility | Lower | High |

| Common Applications | Cutting tools, blades, turbine blades | Food processing equipment, chemical containers, cryogenic vessels |

| Heat Treatment | Required for hardness and strength | Usually not heat treated |

| Typical Grades | Type 410, 420, 440 | Type 304, 316, 321 |

Introduction to Martensitic and Austenitic Structures

Martensitic and austenitic steels differ primarily in their crystal structures, with martensitic steels possessing a body-centered tetragonal (BCT) structure formed through rapid cooling, resulting in high hardness and strength. Austenitic steels feature a face-centered cubic (FCC) structure, stabilized by higher amounts of nickel and manganese, providing excellent corrosion resistance and ductility. The transformation between these structures significantly influences mechanical properties and applications in industries such as automotive and aerospace.

Defining Martensite: Key Characteristics

Martensite is a hard, brittle microstructure formed in steels through rapid cooling, characterized by a body-centered tetragonal (BCT) crystal structure. It exhibits high tensile strength and hardness due to carbon atoms trapped in interstitial sites causing lattice distortion. The transformation to martensite is diffusionless, occurring almost instantaneously during quenching from austenitic phases.

Austenite Explained: Structure and Properties

Austenite is a face-centered cubic (FCC) phase of iron characterized by its high-temperature stability and non-magnetic properties. Its atomic arrangement allows for greater ductility and toughness compared to martensitic structures, making it essential in stainless steels for enhanced corrosion resistance. The ability of austenite to dissolve more carbon contributes to its strength and uniformity, distinguishing it from the body-centered tetragonal (BCT) martensite phase.

Phase Transformation: How Martensite and Austenite Form

Martensitic transformation occurs through a diffusionless, shear-dominated process where the face-centered cubic (FCC) austenite rapidly converts to body-centered tetragonal (BCT) martensite upon rapid cooling or quenching. Austenite forms as a face-centered cubic (FCC) phase when steel is heated to high temperatures, allowing carbon atoms to dissolve uniformly within the iron lattice. The distinct crystallographic mechanisms and temperature conditions govern the phase transformation, with austenite stable at elevated temperatures and martensite forming during non-equilibrium cooling conditions.

Mechanical Properties Comparison

Martensitic stainless steel exhibits higher hardness and tensile strength due to its body-centered tetragonal crystal structure, making it ideal for applications requiring wear resistance and toughness. Austenitic stainless steel, characterized by a face-centered cubic structure, offers superior ductility, corrosion resistance, and toughness but has lower strength compared to martensitic grades. The mechanical performance of martensitic steels is enhanced through heat treatment, while austenitic steels maintain their mechanical properties across a wider range of temperatures.

Corrosion Resistance Differences

Martensitic stainless steel exhibits moderate corrosion resistance due to its higher carbon content and martensitic microstructure, making it more susceptible to pitting and crevice corrosion compared to austenitic stainless steel. Austenitic stainless steel, characterized by its face-centered cubic crystal structure and higher chromium and nickel content, provides superior corrosion resistance in chloride-rich and acidic environments. The enhanced passivation layer in austenitic grades such as 304 and 316 stainless steel ensures better protection against oxidation and chemical attack than martensitic grades like 410 or 420.

Heat Treatment and Processing Techniques

Martensitic stainless steels undergo heat treatment processes such as quenching and tempering to enhance hardness and strength, with precise temperature control crucial for achieving a martensitic microstructure. Austenitic stainless steels, typically non-heat treatable for hardness, rely on cold working techniques like rolling or annealing to improve toughness and corrosion resistance. The fundamental difference in heat treatment lies in martensitic steels transforming their microstructure through rapid cooling, whereas austenitic steels maintain a stable face-centered cubic structure without phase transformation during heat treatment.

Common Applications in Industry

Martensitic stainless steel is widely used in cutlery, surgical instruments, and industrial blades due to its high hardness and wear resistance. Austenitic stainless steel, known for excellent corrosion resistance and ductility, is commonly employed in chemical processing equipment, food industry machinery, and architectural structures. Both types serve critical roles in aerospace components and automotive parts, optimizing performance based on specific mechanical and environmental requirements.

Advantages and Limitations of Each Type

Martensitic stainless steel offers high strength, hardness, and wear resistance due to its high carbon content, making it ideal for cutting tools and structural applications; however, it is prone to corrosion if not properly heat-treated and lacks the excellent corrosion resistance of austenitic grades. Austenitic stainless steel provides superior corrosion resistance, excellent formability, and good toughness, widely used in food processing and chemical industries, but it generally has lower strength and hardness compared to martensitic types. The choice between martensitic and austenitic stainless steel depends on application-specific requirements for mechanical strength versus corrosion resistance and ease of fabrication.

Choosing Between Martensitic and Austenitic Steels

Choosing between martensitic and austenitic steels depends on required mechanical properties and corrosion resistance. Martensitic steels offer high strength and hardness, making them ideal for cutting tools and wear-resistant applications, but they have lower corrosion resistance. Austenitic steels provide excellent corrosion resistance and good toughness, suitable for chemical processing and food industry environments where durability against corrosion is critical.

Martensitic Infographic

libterm.com

libterm.com