Rolling contact reduces friction and wear between moving parts by allowing surfaces to roll over each other instead of sliding. This principle is crucial in applications like bearings, where smooth rotation and durability are essential. Explore the rest of this article to understand how rolling contact can enhance your mechanical systems' performance.

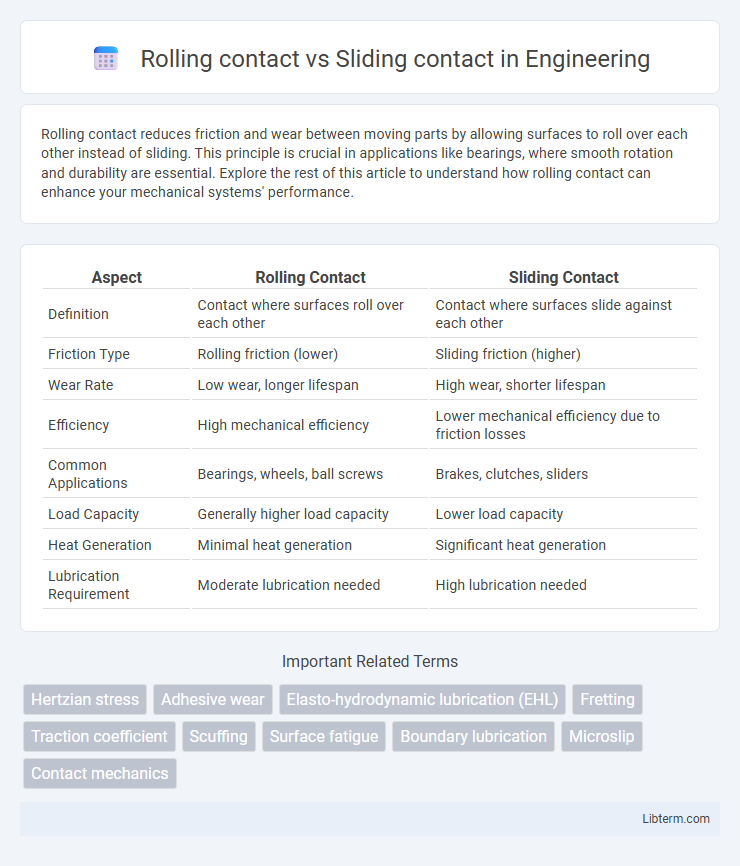

Table of Comparison

| Aspect | Rolling Contact | Sliding Contact |

|---|---|---|

| Definition | Contact where surfaces roll over each other | Contact where surfaces slide against each other |

| Friction Type | Rolling friction (lower) | Sliding friction (higher) |

| Wear Rate | Low wear, longer lifespan | High wear, shorter lifespan |

| Efficiency | High mechanical efficiency | Lower mechanical efficiency due to friction losses |

| Common Applications | Bearings, wheels, ball screws | Brakes, clutches, sliders |

| Load Capacity | Generally higher load capacity | Lower load capacity |

| Heat Generation | Minimal heat generation | Significant heat generation |

| Lubrication Requirement | Moderate lubrication needed | High lubrication needed |

Introduction to Rolling and Sliding Contact

Rolling contact involves two surfaces interacting with relative motion where one surface rolls over the other, minimizing friction and wear through a small contact area typically seen in bearings and wheels. Sliding contact occurs when two surfaces slide against each other, generating higher friction and increased wear, common in applications like brake pads and seals. The fundamental difference lies in the deformation and frictional characteristics, impacting energy efficiency and component lifespan.

Fundamental Differences Between Rolling and Sliding Contact

Rolling contact involves two surfaces rolling over each other with minimal friction and wear, as seen in ball bearings and roller conveyors. Sliding contact occurs when surfaces move directly against each other, generating higher friction, heat, and wear typical in brake pads and gears. The fundamental difference lies in the motion type and contact mechanics, where rolling contact minimizes energy loss and surface damage compared to sliding contact.

Mechanisms of Rolling Contact

Rolling contact involves two surfaces moving relative to each other with minimal sliding, where deformation occurs primarily at the contact points, forming a localized contact patch that distributes load efficiently. This mechanism reduces friction and wear compared to sliding contact by maintaining a rolling motion that limits surface asperity interaction and material transfer. Components such as ball bearings and roller bearings exemplify rolling contact, utilizing rolling elements to sustain load and motion with enhanced durability and energy efficiency.

Mechanisms of Sliding Contact

Sliding contact involves direct surface interaction where friction and wear occur due to relative tangential motion between contacting bodies, causing adhesive and abrasive mechanisms. The surface asperities deform plastically or fracture, leading to material transfer, increased heat generation, and surface fatigue. This contrasts with rolling contact, where deformation is primarily elastic, minimizing energy loss and wear.

Frictional Characteristics: Rolling vs Sliding

Rolling contact exhibits significantly lower friction compared to sliding contact due to the reduced area of surface interaction and minimal relative motion at the contact interface. The frictional force in rolling contact primarily arises from deformation and material hysteresis, resulting in a coefficient of rolling friction typically ranging from 0.001 to 0.02, whereas sliding contact involves higher shear forces and adhesion, with coefficients of sliding friction often between 0.1 and 0.6. This fundamental difference in frictional characteristics makes rolling contact preferable in applications requiring efficiency and reduced wear, such as bearings and wheels, compared to sliding contact found in plain bearings and brake pads.

Wear and Tear Comparison

Rolling contact significantly reduces wear and tear compared to sliding contact due to lower friction coefficients, minimizing surface degradation. Sliding contact involves direct surface friction that accelerates material loss and heat generation, leading to faster component failure. Bearings and wheels utilize rolling contact to enhance durability and maintain performance under high load conditions.

Applications of Rolling Contact

Rolling contact is widely applied in mechanical components such as ball bearings, roller bearings, and gear systems, where low friction and wear resistance are critical for efficiency and longevity. These applications benefit from reduced energy loss and increased durability, making rolling contact ideal for automotive wheels, conveyor rollers, and precision machinery. The ability to maintain smooth motion under high load conditions distinguishes rolling contact mechanisms in industrial and transportation sectors.

Applications of Sliding Contact

Sliding contact finds extensive applications in machinery components such as bearings, seals, and clutches, where surfaces move relative to each other under load. It is crucial in linear actuators and conveyor systems that require precise control of motion and force transmission. The sliding contact also plays a vital role in electrical brushes of motors and generators, enabling efficient current transfer with minimal wear.

Advantages and Disadvantages of Each Contact Type

Rolling contact reduces friction by minimizing surface area interaction, leading to lower wear and energy loss, but requires more complex design and maintenance. Sliding contact allows simpler construction and better load distribution but suffers from higher friction, increased wear, and greater heat generation. The choice depends on application demands, balancing efficiency and durability against system complexity and maintenance requirements.

Choosing the Right Contact Method for Your Application

Choosing between rolling contact and sliding contact depends on factors like load capacity, speed, and wear resistance. Rolling contact reduces friction and heat generation, making it ideal for high-speed applications with moderate loads, while sliding contact suits low-speed, high-load scenarios due to its simplicity and ability to handle heavy loads. Evaluating specific application requirements, such as maintenance intervals and environmental conditions, ensures optimal performance and longevity of the mechanical system.

Rolling contact Infographic

libterm.com

libterm.com