Additive manufacturing, commonly known as 3D printing, revolutionizes production by building objects layer by layer directly from digital models, allowing for unprecedented design flexibility and material efficiency. This technology reduces waste, accelerates prototyping, and enables customization in industries ranging from aerospace to healthcare. Discover how additive manufacturing can transform your projects by exploring the advantages and applications detailed in this article.

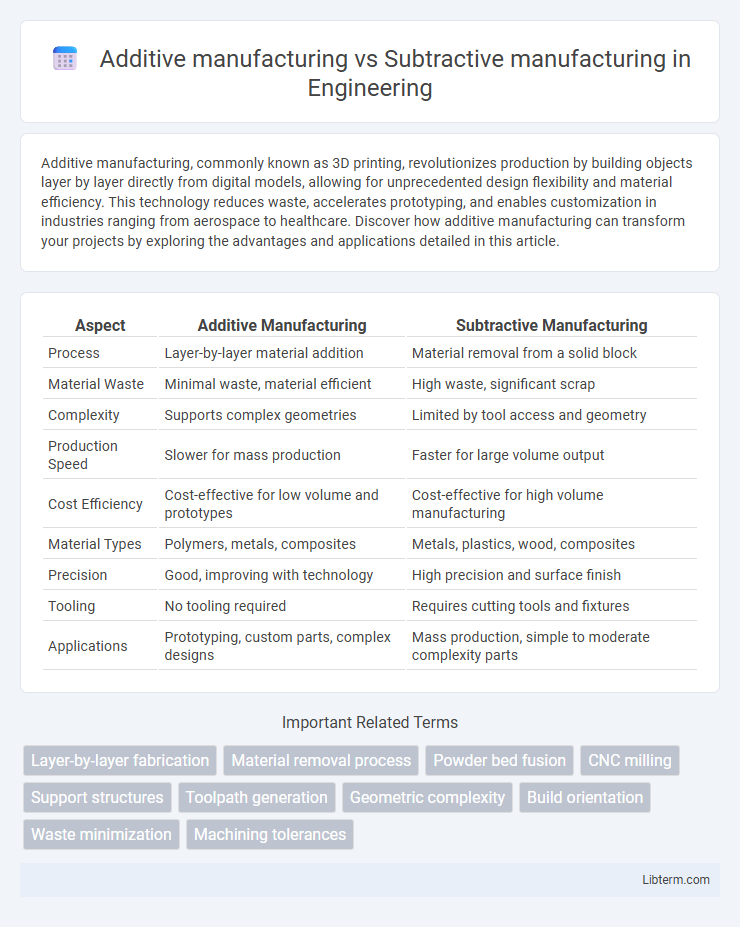

Table of Comparison

| Aspect | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Process | Layer-by-layer material addition | Material removal from a solid block |

| Material Waste | Minimal waste, material efficient | High waste, significant scrap |

| Complexity | Supports complex geometries | Limited by tool access and geometry |

| Production Speed | Slower for mass production | Faster for large volume output |

| Cost Efficiency | Cost-effective for low volume and prototypes | Cost-effective for high volume manufacturing |

| Material Types | Polymers, metals, composites | Metals, plastics, wood, composites |

| Precision | Good, improving with technology | High precision and surface finish |

| Tooling | No tooling required | Requires cutting tools and fixtures |

| Applications | Prototyping, custom parts, complex designs | Mass production, simple to moderate complexity parts |

Introduction to Manufacturing Processes

Additive manufacturing builds objects layer by layer using materials like plastics, metals, or resins, enabling complex geometries and minimal waste. Subtractive manufacturing removes material from a solid block through machining processes such as milling, turning, or drilling to achieve precise dimensions and surface finishes. Both methods are fundamental in modern manufacturing, with additive offering design freedom and rapid prototyping, while subtractive ensures high accuracy and material consistency.

Overview of Additive Manufacturing

Additive manufacturing builds objects layer by layer from digital models using materials such as plastics, metals, or composites, enabling complex geometries and minimal waste. This process supports rapid prototyping, customization, and reduced lead times compared to traditional subtractive methods, which remove material from solids. Industry applications range from aerospace to medical implants, showcasing additive manufacturing's flexibility and efficiency in producing lightweight, high-strength parts.

Overview of Subtractive Manufacturing

Subtractive manufacturing involves removing material from a solid block using machining processes such as milling, turning, or drilling to create precise components. This method offers high accuracy and surface finish, making it ideal for producing complex metal parts in aerospace, automotive, and medical industries. Despite generating more waste compared to additive manufacturing, subtractive techniques are well-established and cost-effective for high-volume production with tight tolerances.

Key Differences Between Additive and Subtractive Manufacturing

Additive manufacturing builds objects layer by layer using materials like polymers, metals, or composites, enabling complex geometries and minimal waste. Subtractive manufacturing removes material from a solid block through cutting, drilling, or milling, making it suitable for high-precision parts with limited complexity. Additive processes excel in rapid prototyping and customization, while subtractive methods offer superior surface finish and dimensional accuracy.

Material Compatibility and Selection

Additive manufacturing supports a broader range of complex geometries and allows for the use of diverse materials such as thermoplastics, metals, and composites, often enabling lightweight and customized parts. Subtractive manufacturing primarily works with rigid materials like metals, plastics, and wood, requiring careful selection to withstand machining forces and tooling constraints. Material compatibility in additive processes often emphasizes layer adhesion and thermal properties, whereas subtractive methods prioritize machinability, hardness, and surface finish quality.

Design Flexibility and Complexity

Additive manufacturing enables greater design flexibility by building components layer by layer, allowing intricate geometries and internal structures that are impossible with traditional subtractive methods. Subtractive manufacturing relies on material removal from a solid block, limiting complexity due to tool access and geometry constraints. Complex parts with internal features or customized designs are more efficiently produced through additive processes, enhancing innovation and reducing material waste.

Precision, Tolerances, and Surface Finish

Additive manufacturing excels in creating complex geometries with high precision but typically offers wider tolerances compared to subtractive manufacturing, which achieves tighter tolerances through material removal processes. Precision in subtractive manufacturing allows for superior surface finish quality, often requiring minimal post-processing, while additive processes may need additional smoothing techniques to enhance surface texture. The choice between these methods depends on the application's demand for dimensional accuracy and surface smoothness, with subtractive manufacturing favored for higher tolerance and finer finishes.

Cost Analysis and Production Efficiency

Additive manufacturing reduces material waste by using only necessary material, leading to lower raw material costs compared to subtractive manufacturing, which involves cutting away excess material. Production efficiency in additive manufacturing excels with complex geometries and small batch sizes, while subtractive methods are faster and more cost-effective for high-volume, simple designs due to established tooling processes. Cost analysis shows additive manufacturing incurs higher initial equipment investment but benefits from reduced labor and material costs, whereas subtractive manufacturing demands ongoing expenses for tooling maintenance and material wastage.

Environmental Impact and Waste Management

Additive manufacturing significantly reduces material waste by building products layer-by-layer, using only the necessary material, which minimizes scrap compared to subtractive manufacturing that often involves cutting away excess material and generating substantial waste. The energy consumption of additive processes can be lower, especially when using efficient machines and sustainable materials, while subtractive methods typically require higher energy for machining and waste disposal. Effective waste management in additive manufacturing involves recycling unused powders and optimizing design to reduce support structures, whereas subtractive manufacturing often struggles with recycling metal chips and handling hazardous cutting fluids.

Choosing the Right Manufacturing Method for Your Application

Additive manufacturing excels in producing complex geometries and customized parts with minimal waste, making it ideal for prototyping and low-volume production. Subtractive manufacturing offers high precision and surface finish for mass production of standardized components through material removal processes. Selecting the right manufacturing method depends on factors such as design complexity, production volume, material properties, and cost-efficiency requirements for the specific application.

Additive manufacturing Infographic

libterm.com

libterm.com