A resolver is an electromechanical device used to measure the angular position or speed of a rotating shaft with high precision. It converts mechanical rotation into corresponding electrical signals, making it essential for applications in robotics, aerospace, and industrial automation. Discover how a resolver can enhance your system's accuracy by exploring the detailed insights in the rest of this article.

Table of Comparison

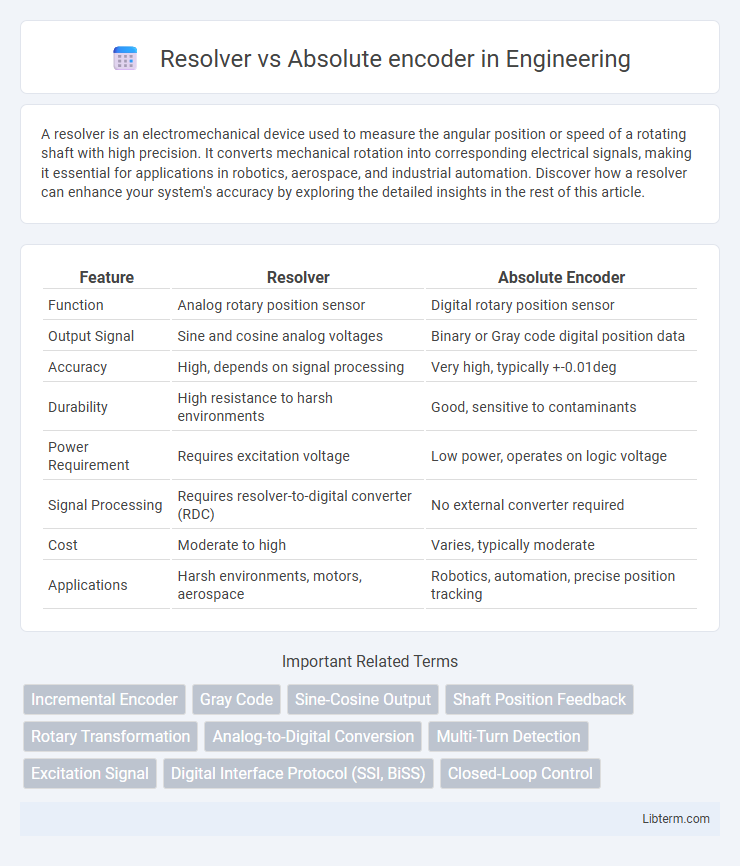

| Feature | Resolver | Absolute Encoder |

|---|---|---|

| Function | Analog rotary position sensor | Digital rotary position sensor |

| Output Signal | Sine and cosine analog voltages | Binary or Gray code digital position data |

| Accuracy | High, depends on signal processing | Very high, typically +-0.01deg |

| Durability | High resistance to harsh environments | Good, sensitive to contaminants |

| Power Requirement | Requires excitation voltage | Low power, operates on logic voltage |

| Signal Processing | Requires resolver-to-digital converter (RDC) | No external converter required |

| Cost | Moderate to high | Varies, typically moderate |

| Applications | Harsh environments, motors, aerospace | Robotics, automation, precise position tracking |

Introduction to Resolver and Absolute Encoder

A resolver is an electromechanical device that converts angular position into analog signals using a rotor and stator configuration, commonly used for precise motor feedback in harsh environments due to its robustness and immunity to electrical noise. An absolute encoder provides a unique digital code for each shaft position, enabling precise and error-free position tracking even after power loss. Both technologies serve critical roles in motion control systems, with resolvers favored for durability and absolute encoders preferred for direct digital position readouts.

Working Principles: Resolver vs Absolute Encoder

A resolver operates using electromagnetic induction to produce analog sine and cosine signals that represent rotor position, which requires decoding to determine the precise angle. An absolute encoder employs optical or magnetic sensors to directly generate a unique digital code for each shaft position, providing a direct and easily interpretable output. The resolver's robust analog signals suit harsh environments, while the absolute encoder offers high-resolution, straightforward digital position feedback.

Key Differences Between Resolver and Absolute Encoder

Resolvers provide analog sine and cosine signals representing rotor position, enabling robust operation in high-temperature and high-vibration environments, while absolute encoders deliver digital position data with multi-turn and single-turn precision. Resolvers rely on electromagnetic induction and typically require external signal processing, whereas absolute encoders integrate on-board electronics for direct digital output and easier interfacing. Absolute encoders offer higher resolution and straightforward integration into control systems, making them ideal for applications needing precise and absolute position feedback.

Accuracy and Resolution Comparison

Resolvers provide robust angular position feedback with moderate accuracy typically around +-0.1deg to +-0.5deg, while absolute encoders offer higher precision often reaching resolutions down to 12 to 16 bits or better, equating to sub-degree accuracy. Absolute encoders deliver superior resolution through digital output, enabling precise position detection essential for applications requiring fine angular measurement. Resolvers excel in harsh environments with electromagnetic interference and temperature variations, but absolute encoders outperform them in terms of accuracy and resolution in controlled settings.

Industrial Applications: Resolver vs Absolute Encoder

Resolvers and absolute encoders serve critical roles in industrial applications requiring precise position feedback. Resolvers excel in harsh environments due to their rugged construction and immunity to electrical noise, making them ideal for heavy-duty machinery and aerospace systems. Absolute encoders provide precise position data with multi-turn tracking capabilities, widely used in robotics, CNC machines, and automated assembly lines where accurate and continuous position information is essential.

Environmental Robustness and Reliability

Resolvers exhibit superior environmental robustness and reliability due to their inherent construction using magnetic coupling, which provides excellent resistance to extreme temperatures, vibrations, moisture, and electromagnetic interference. Absolute encoders, while offering precise position tracking through optical or magnetic sensors, can be more vulnerable to dust, dirt, and harsh environmental conditions, potentially affecting long-term reliability. Industrial applications demanding durability in challenging environments often prefer resolvers for their proven resilience and consistent performance.

Integration and Compatibility Considerations

Resolvers offer robust integration with harsh industrial environments due to their simple construction and inherent immunity to electrical noise, making them highly compatible with legacy systems requiring analog signal processing. Absolute encoders provide direct digital position data with higher resolution and ease of integration into modern automation systems using standard communication protocols such as SSI, CANopen, or Ethernet/IP. Compatibility considerations favor resolvers in high-temperature or high-vibration settings, while absolute encoders excel in applications needing precise, real-time position feedback with seamless integration into PLCs and motion controllers.

Cost Analysis: Resolver vs Absolute Encoder

Resolvers offer a cost-effective solution for harsh environments due to their robust, brushless design and simple construction, which reduces maintenance expenses compared to absolute encoders. Absolute encoders typically incur higher initial costs because of complex electronics and precision optical components but provide enhanced resolution and direct position feedback that can lower system integration costs. Evaluating total ownership costs reveals resolvers excel in longevity and reliability in extreme conditions, while absolute encoders may justify their higher price through improved accuracy and advanced features in controlled applications.

Maintenance and Lifespan

Resolvers offer exceptional durability and low maintenance due to their rugged construction and immunity to dust, moisture, and vibration, resulting in longer operational lifespan in harsh environments. Absolute encoders typically require more frequent calibration and cleaning to maintain accuracy, as their optical or magnetic sensors can be sensitive to contaminants and wear over time. Consequently, resolvers are preferred in applications demanding minimal maintenance and extended lifespan, while absolute encoders suit systems needing precise positional data but with regular servicing.

Choosing the Right Technology for Your Application

Choosing between a resolver and an absolute encoder depends on application requirements such as environmental conditions, precision, and reliability. Resolvers excel in harsh environments due to their robust, non-contact magnetic rotary sensing, while absolute encoders offer high-resolution position feedback with direct angular measurement. Factors like electrical noise immunity, installation complexity, and cost also influence the decision, making it essential to match the encoder type to specific operational demands and accuracy needs.

Resolver Infographic

libterm.com

libterm.com