Milling is a versatile machining process that removes material from a workpiece using rotary cutters to shape and finish it with high precision. It is widely used in manufacturing industries to create complex parts with intricate details and tight tolerances. Explore the rest of the article to understand how milling can enhance your production capabilities and product quality.

Table of Comparison

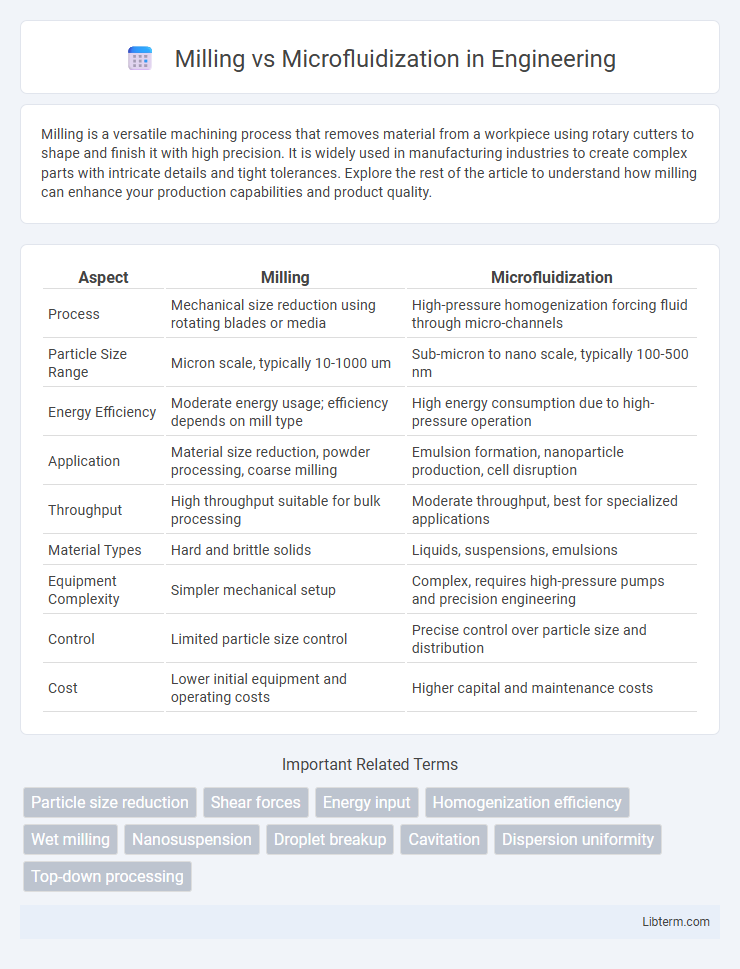

| Aspect | Milling | Microfluidization |

|---|---|---|

| Process | Mechanical size reduction using rotating blades or media | High-pressure homogenization forcing fluid through micro-channels |

| Particle Size Range | Micron scale, typically 10-1000 um | Sub-micron to nano scale, typically 100-500 nm |

| Energy Efficiency | Moderate energy usage; efficiency depends on mill type | High energy consumption due to high-pressure operation |

| Application | Material size reduction, powder processing, coarse milling | Emulsion formation, nanoparticle production, cell disruption |

| Throughput | High throughput suitable for bulk processing | Moderate throughput, best for specialized applications |

| Material Types | Hard and brittle solids | Liquids, suspensions, emulsions |

| Equipment Complexity | Simpler mechanical setup | Complex, requires high-pressure pumps and precision engineering |

| Control | Limited particle size control | Precise control over particle size and distribution |

| Cost | Lower initial equipment and operating costs | Higher capital and maintenance costs |

Introduction to Milling and Microfluidization

Milling is a mechanical process that reduces particle size through grinding, cutting, or crushing using various types of mills such as ball mills, jet mills, or hammer mills. Microfluidization utilizes high-pressure streams forced through microchannels to create intense shear and impact forces, resulting in uniform particle or droplet size reduction. Both techniques are widely employed in pharmaceutical, cosmetic, and food industries to enhance product bioavailability and stability by achieving fine dispersion and homogenization.

Core Principles of Milling

Milling operates by mechanically breaking down particles through shear, impact, and compression forces generated by rotating blades or media within a mill chamber. This process reduces particle size by physically grinding materials into finer powders, enhancing surface area and reactivity. Key parameters influencing milling efficiency include rotor speed, feed rate, and milling duration, which determine the final particle size distribution and product consistency.

How Microfluidization Works

Microfluidization works by forcing fluids through microchannels at extremely high pressures, typically between 50,000 and 30,000 psi, creating intense shear, impact, and cavitation forces that break down particles to nanoscale sizes. This high-pressure interaction results in highly uniform particle size distribution and enhanced product stability compared to traditional milling, which relies on mechanical grinding. Microfluidization's precise control over shear forces makes it ideal for producing nanoemulsions, liposomes, and fine dispersions in pharmaceutical, food, and cosmetic industries.

Key Differences between Milling and Microfluidization

Milling reduces particle size through mechanical attrition using rotating blades or balls, producing a broad size distribution and potential heat generation, whereas microfluidization employs high-pressure streams forcing fluids through micro-channels, resulting in uniform nanoparticles with enhanced dispersion stability. Milling is suitable for coarse material size reduction but often leads to uneven particle sizes and contamination risks, while microfluidization achieves finer emulsions and nano-scale particles ideal for pharmaceuticals and food processing. The choice depends on desired particle uniformity, scale, and application specificity, with microfluidization offering superior control and reproducibility in particle size distribution.

Particle Size Reduction Efficiency

Milling achieves particle size reduction through mechanical attrition, typically producing particles in the micrometer range with efficiencies dependent on mill type and operating conditions. Microfluidization employs high-pressure homogenization, generating shear forces that reduce particle sizes to the sub-micron and nano scale with higher uniformity and reproducibility. Comparative studies show microfluidization outperforms traditional milling in achieving finer particle size distributions and enhanced stability for pharmaceutical and food applications.

Applications in Different Industries

Milling and microfluidization serve critical roles across diverse industries, with milling widely used for particle size reduction in pharmaceuticals, food processing, and ceramics to enhance texture and solubility. Microfluidization excels in producing uniform nanoemulsions and liposomes, vital in biotech, cosmetics, and nutraceuticals for improved bioavailability and stability. Both technologies are pivotal for material refinement, yet microfluidization offers superior control at the nanoscale, crucial for advanced drug delivery and high-performance formulations.

Advantages of Milling

Milling offers precise particle size reduction suitable for producing consistent, uniform particles that enhance solubility and bioavailability in pharmaceutical and cosmetic formulations. It is cost-effective with scalable equipment options that accommodate both small and large production volumes efficiently. Milling processes exhibit versatility by handling a wide range of materials, including hard, abrasive, and wet substances, without significant heat generation that could degrade sensitive compounds.

Benefits of Microfluidization

Microfluidization offers superior particle size reduction compared to traditional milling, resulting in more uniform and stable emulsions critical for pharmaceutical and cosmetic applications. It utilizes high-pressure homogenization to enhance bioavailability and improve texture without generating excessive heat, preserving the integrity of sensitive bioactive compounds. This technique also provides scalable and reproducible processing, reducing batch-to-batch variability and improving overall product consistency.

Challenges and Limitations of Each Method

Milling faces challenges such as broad particle size distribution, potential contamination from grinding media, and heat generation that can degrade sensitive materials. Microfluidization offers uniform particle size reduction but is limited by high equipment costs, complex operation, and difficulty processing highly viscous or abrasive materials. Both methods require careful optimization to balance efficiency, product quality, and scalability in pharmaceutical and food applications.

Conclusion: Selecting the Right Technology

Choosing between milling and microfluidization depends on the desired particle size, product consistency, and processing scale. Milling is effective for coarse to fine particle reduction with versatile equipment options, while microfluidization offers superior uniformity and nanoscale particle size for high-performance formulations. Evaluating factors such as throughput, energy consumption, and end-product requirements ensures optimal technology selection for specific industrial or pharmaceutical applications.

Milling Infographic

libterm.com

libterm.com