Stress corrosion cracking occurs when tensile stress and a corrosive environment interact, leading to sudden and unexpected material failure. This phenomenon often affects metals in critical structures, causing microscopic cracks that can propagate rapidly under persistent stress. Discover how to identify, prevent, and mitigate stress corrosion cracking to protect your assets by reading the full article.

Table of Comparison

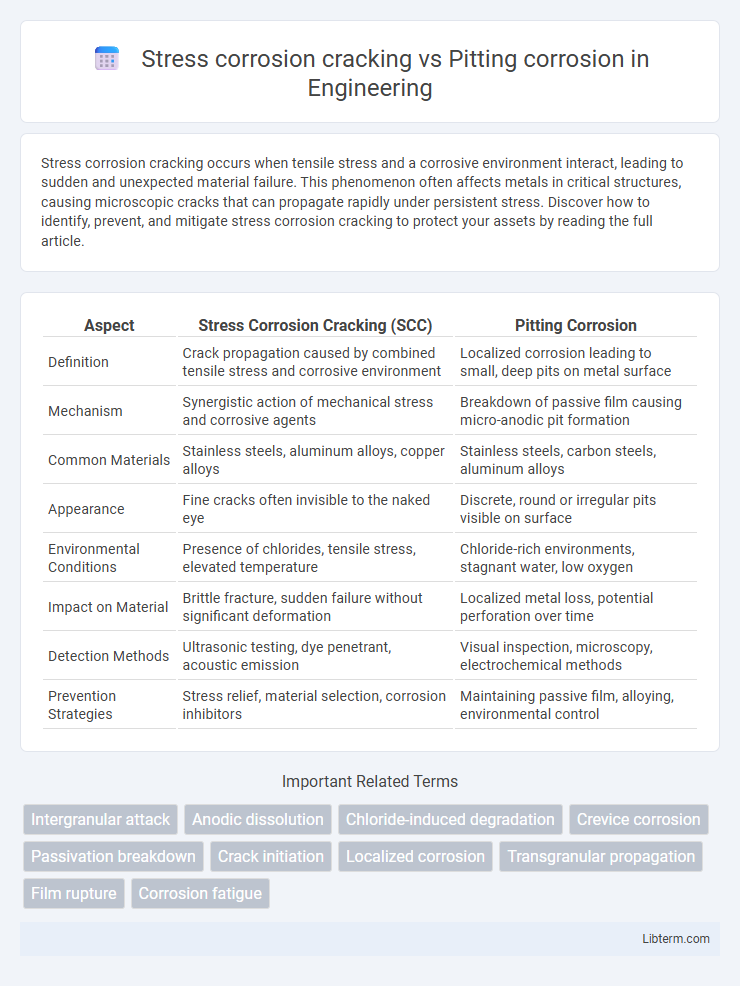

| Aspect | Stress Corrosion Cracking (SCC) | Pitting Corrosion |

|---|---|---|

| Definition | Crack propagation caused by combined tensile stress and corrosive environment | Localized corrosion leading to small, deep pits on metal surface |

| Mechanism | Synergistic action of mechanical stress and corrosive agents | Breakdown of passive film causing micro-anodic pit formation |

| Common Materials | Stainless steels, aluminum alloys, copper alloys | Stainless steels, carbon steels, aluminum alloys |

| Appearance | Fine cracks often invisible to the naked eye | Discrete, round or irregular pits visible on surface |

| Environmental Conditions | Presence of chlorides, tensile stress, elevated temperature | Chloride-rich environments, stagnant water, low oxygen |

| Impact on Material | Brittle fracture, sudden failure without significant deformation | Localized metal loss, potential perforation over time |

| Detection Methods | Ultrasonic testing, dye penetrant, acoustic emission | Visual inspection, microscopy, electrochemical methods |

| Prevention Strategies | Stress relief, material selection, corrosion inhibitors | Maintaining passive film, alloying, environmental control |

Introduction to Corrosion Mechanisms

Stress corrosion cracking (SCC) occurs when tensile stress and a corrosive environment combine to initiate and propagate cracks in metals, often leading to sudden catastrophic failure. Pitting corrosion is a localized form of corrosion resulting in small, deep cavities or pits on the metal surface caused by the breakdown of passive films in specific areas. Both mechanisms degrade metal integrity but differ as SCC involves crack propagation under stress, while pitting is primarily a surface-localized attack.

Defining Stress Corrosion Cracking

Stress corrosion cracking (SCC) is a failure mechanism characterized by the growth of cracks in a corrosive environment under tensile stress, often leading to sudden and catastrophic material failure. Unlike pitting corrosion, which involves localized surface pits, SCC propagates beneath the surface and compromises structural integrity. SCC commonly affects metals such as stainless steel and aluminum alloys exposed to specific corrosive media and sustained mechanical stress.

Understanding Pitting Corrosion

Pitting corrosion is a localized form of corrosion that leads to the creation of small cavities or pits on metal surfaces, often in stainless steels and other passive metals exposed to chloride environments. Unlike stress corrosion cracking, which involves the combined influence of tensile stress and corrosive media resulting in crack formation, pitting corrosion primarily causes structural weakness by concentrating damage in discrete spots that are difficult to detect and predict. Understanding the electrochemical mechanisms and environmental factors that initiate pitting is crucial for preventing sudden failures in pipelines, marine structures, and industrial equipment.

Key Differences Between SCC and Pitting

Stress corrosion cracking (SCC) primarily occurs due to the combined effect of tensile stress and a corrosive environment, leading to the formation of fine cracks that propagate through the material. In contrast, pitting corrosion is characterized by localized, often deep pits or holes on the surface without necessarily involving mechanical stress. While SCC causes brittle failure and is sensitive to stress intensity and metallurgical factors, pitting corrosion is mainly influenced by chemical composition and environmental conditions such as chloride concentration.

Common Causes of Stress Corrosion Cracking

Stress corrosion cracking (SCC) commonly occurs due to the combined influence of tensile stress and a corrosive environment, often involving chlorides, caustic substances, or specific metal ions like copper or nickel that attack susceptible alloys. Pitting corrosion, in contrast, results from localized breakdown of passive films on metals, creating small, deep cavities or pits typically initiated by chloride ions. The critical factors driving SCC include sustained tensile stresses, specific environmental chemistries such as chloride-rich solutions, and the metallurgical susceptibility of materials like stainless steels, nickel alloys, or aluminum alloys.

Factors Influencing Pitting Corrosion

Pitting corrosion predominantly occurs in passive metals such as stainless steel and aluminum, influenced by factors like chloride ion concentration, temperature, and pH levels, which destabilize the protective oxide film. The presence of crevices, high tensile stress, and localized chemical environments further exacerbate pit initiation and propagation. Unlike stress corrosion cracking that requires tensile stress and susceptible microstructure, pitting corrosion mainly depends on environmental aggressiveness and alloy composition.

Materials Susceptible to SCC and Pitting

Stress corrosion cracking (SCC) commonly affects high-strength alloys such as austenitic stainless steels, carbon steels, and aluminum alloys exposed to tensile stress and corrosive environments containing chlorides or caustic substances. Pitting corrosion primarily targets passive metals like stainless steels, titanium, and nickel alloys when localized breakdown of the protective oxide layer occurs, especially in chloride-rich environments. Both SCC and pitting corrosion demand careful material selection and environmental control to prevent premature failure in critical industrial applications.

Detection and Diagnosis Techniques

Stress corrosion cracking (SCC) detection primarily relies on non-destructive testing methods such as ultrasonic testing, acoustic emission monitoring, and dye penetrant inspection, which can identify fine cracks caused by tensile stress and corrosive environments. Pitting corrosion diagnosis utilizes visual inspection, radiography, and eddy current testing to detect localized metal loss characterized by small, deep cavities. Advanced techniques like scanning electron microscopy (SEM) and X-ray computed tomography (XCT) offer detailed surface and subsurface analysis, improving the accuracy of both SCC and pitting corrosion detection.

Prevention and Mitigation Strategies

Stress corrosion cracking (SCC) prevention focuses on controlling tensile stress through proper design, such as reducing residual stresses via heat treatment or mechanical stress relief, and selecting corrosion-resistant alloys like stainless steel or nickel-based alloys. Pitting corrosion mitigation involves maintaining protective passive films by controlling environmental factors, such as reducing chloride concentration, using corrosion inhibitors, and ensuring proper cleaning and drying to prevent localized acidification. Both require regular inspection techniques like ultrasonic testing for SCC and visual or electrochemical methods for pitting to detect early damage and enable timely maintenance.

Industry Applications and Case Studies

Stress corrosion cracking (SCC) primarily affects high-strength alloys in industries like aerospace and petrochemical, where tensile stress and corrosive environments coexist, leading to catastrophic failures as seen in aircraft fuselage cracking and pipeline ruptures. Pitting corrosion is prevalent in marine and chemical processing sectors, targeting stainless steels and aluminum, with case studies documenting severe localized damage in offshore platforms and storage tanks that compromise structural integrity. Both corrosion types demand tailored monitoring and mitigation strategies, such as stress relief treatments and corrosion inhibitors, to ensure reliability and safety in critical industrial applications.

Stress corrosion cracking Infographic

libterm.com

libterm.com