The thermoelectric effect converts temperature differences directly into electrical voltage, enabling efficient energy harvesting and cooling applications. Materials with high thermoelectric efficiency are crucial for optimizing power generation in renewable energy systems and waste heat recovery. Discover how understanding the thermoelectric effect can improve Your energy solutions by reading the full article.

Table of Comparison

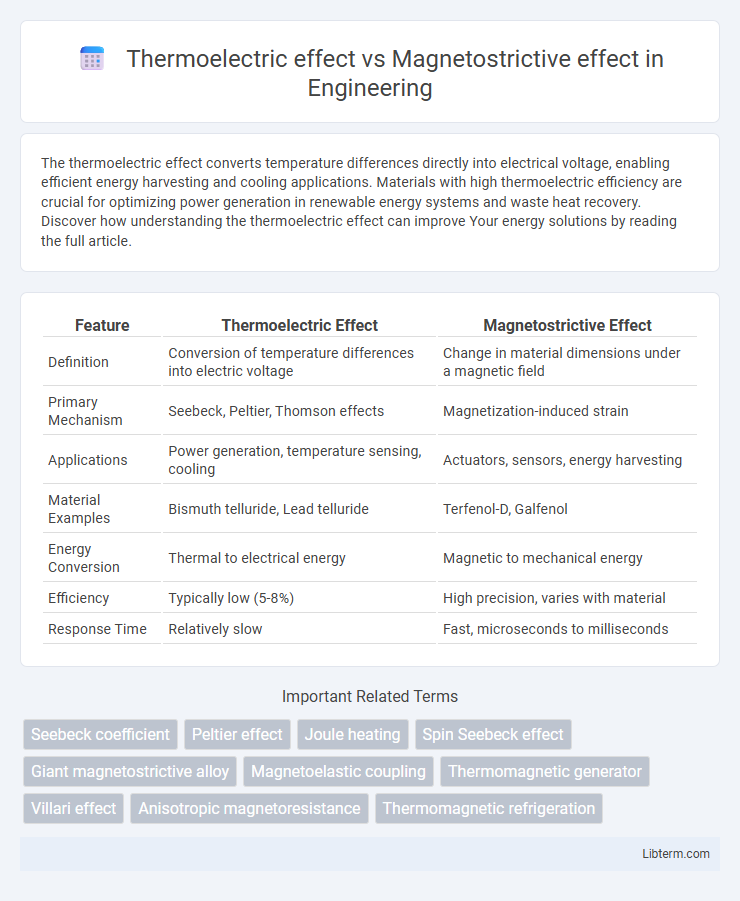

| Feature | Thermoelectric Effect | Magnetostrictive Effect |

|---|---|---|

| Definition | Conversion of temperature differences into electric voltage | Change in material dimensions under a magnetic field |

| Primary Mechanism | Seebeck, Peltier, Thomson effects | Magnetization-induced strain |

| Applications | Power generation, temperature sensing, cooling | Actuators, sensors, energy harvesting |

| Material Examples | Bismuth telluride, Lead telluride | Terfenol-D, Galfenol |

| Energy Conversion | Thermal to electrical energy | Magnetic to mechanical energy |

| Efficiency | Typically low (5-8%) | High precision, varies with material |

| Response Time | Relatively slow | Fast, microseconds to milliseconds |

Introduction to Thermoelectric and Magnetostrictive Effects

Thermoelectric effects involve the direct conversion between temperature differences and electric voltage, prominently utilized in power generation and refrigeration through the Seebeck and Peltier effects. Magnetostrictive effects occur when ferromagnetic materials change their shape or dimensions in response to an applied magnetic field, enabling applications in sensors, actuators, and transducers. Both phenomena harness the interplay between physical stimuli and material responses, forming the basis for advanced energy harvesting and precision control technologies.

Fundamental Principles of the Thermoelectric Effect

The thermoelectric effect is based on the Seebeck, Peltier, and Thomson phenomena, where temperature differences within a material generate an electric voltage or, conversely, electric currents induce heating or cooling. This effect relies on charge carrier diffusion driven by thermal gradients, leading to energy conversion between heat and electricity without moving parts. In contrast, the magnetostrictive effect involves changes in a material's shape or dimensions due to magnetic field variations, relying on magnetization-induced mechanical strain rather than thermal energy transport.

Core Mechanisms of Magnetostrictive Effect

The magnetostrictive effect occurs when certain ferromagnetic materials change shape or dimensions in response to an applied magnetic field due to the realignment of magnetic domains. This core mechanism involves the coupling of magnetic and elastic energies, causing strain or deformation without electrical input. Unlike the thermoelectric effect, which converts thermal gradients into electrical voltage through charge carrier diffusion, the magnetostrictive effect directly translates magnetic energy into mechanical energy.

Historical Development and Key Discoveries

The thermoelectric effect was first observed in 1821 by Thomas Johann Seebeck, who discovered that a circuit made from two different metals generates an electric current when subjected to a temperature gradient. In contrast, the magnetostrictive effect was discovered in 1842 by James Joule, who found that ferromagnetic materials change shape or dimension under the influence of a magnetic field. These key discoveries laid the foundation for thermoelectric generators and magnetostrictive sensors, respectively, driving advancements in energy conversion and precision actuation technologies.

Materials Exhibiting Thermoelectric Properties

Materials exhibiting thermoelectric properties include bismuth telluride, lead telluride, and silicon-germanium alloys, known for their ability to convert temperature gradients into electrical voltage through the Seebeck effect. These materials are characterized by high Seebeck coefficients, low thermal conductivity, and high electrical conductivity, optimizing their thermoelectric performance. In contrast, magnetostrictive materials such as Terfenol-D and Galfenol respond to magnetic fields by changing shape rather than generating electrical energy from thermal gradients.

Common Magnetostrictive Materials

Common magnetostrictive materials include Terfenol-D, an alloy of terbium, dysprosium, and iron, known for its high magnetostriction and energy conversion efficiency. These materials change shape in response to magnetic fields, enabling applications in sensors and actuators. Unlike the thermoelectric effect, which converts temperature differences into electrical voltage, magnetostrictive materials convert magnetic energy into mechanical strain, offering distinct functionalities in energy harvesting and signal transduction.

Applications of Thermoelectric Technology

Thermoelectric technology is widely applied in power generation, waste heat recovery, and precise temperature control in electronics and medical devices. It enables efficient conversion of temperature gradients into electrical energy, making it valuable in automotive thermoelectric generators and remote sensing applications. Unlike magnetostrictive effect technologies used primarily in sensors and actuators, thermoelectric devices offer silent, solid-state energy conversion without moving parts, enhancing durability and reliability.

Uses of Magnetostrictive Devices

Magnetostrictive devices are extensively used in precision sensors, actuators, and ultrasonic transducers due to their ability to convert magnetic energy into mechanical strain with high accuracy. These devices enable applications in sonar systems, vibration control, and position sensing by exploiting the magnetostrictive effect for reliable and responsive performance. Unlike thermoelectric devices focused on heat-to-electricity conversion, magnetostrictive devices specialize in mechanical movement and sensing, making them essential in advanced industrial and medical technologies.

Comparative Analysis: Thermoelectric vs Magnetostrictive Effects

Thermoelectric effects involve the direct conversion of temperature differences into electric voltage, primarily utilized in power generation and temperature sensing applications with materials like bismuth telluride. Magnetostrictive effects generate mechanical deformation in ferromagnetic materials such as Terfenol-D when exposed to magnetic fields, enabling applications in actuators and sensors. Comparative analysis highlights thermoelectric materials excel in energy harvesting from thermal gradients, whereas magnetostrictive materials offer rapid mechanical response and high energy density in magnetic field-driven environments.

Future Trends and Research Directions

Future trends in the thermoelectric effect emphasize enhancing material efficiency through nanostructuring and exploring novel compounds like topological insulators to boost energy conversion rates. Research directions for magnetostrictive effects prioritize the development of smart sensors and actuators with improved sensitivity and miniaturization using advanced composites and thin-film technologies. Both fields increasingly integrate multidisciplinary approaches, leveraging computational modeling and machine learning to optimize material properties and device performance.

Thermoelectric effect Infographic

libterm.com

libterm.com