Resistance welding efficiently joins metal pieces by applying heat generated from electrical resistance at the contact surfaces, ensuring strong and reliable bonds. This technique is widely used in automotive, aerospace, and manufacturing industries due to its precision and speed. Explore the rest of the article to understand how resistance welding can enhance your production processes.

Table of Comparison

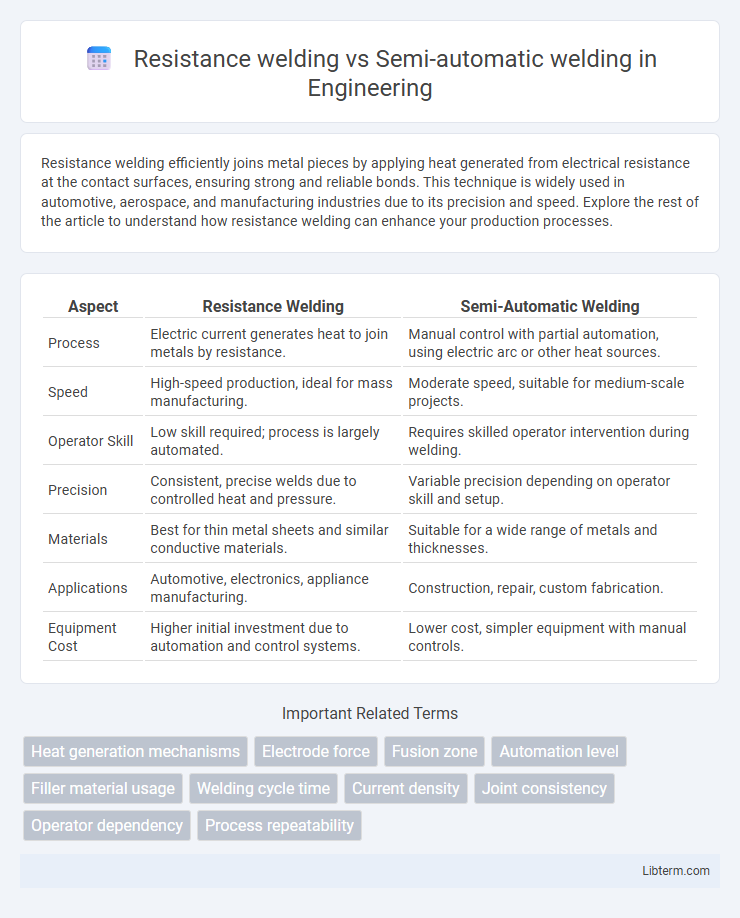

| Aspect | Resistance Welding | Semi-Automatic Welding |

|---|---|---|

| Process | Electric current generates heat to join metals by resistance. | Manual control with partial automation, using electric arc or other heat sources. |

| Speed | High-speed production, ideal for mass manufacturing. | Moderate speed, suitable for medium-scale projects. |

| Operator Skill | Low skill required; process is largely automated. | Requires skilled operator intervention during welding. |

| Precision | Consistent, precise welds due to controlled heat and pressure. | Variable precision depending on operator skill and setup. |

| Materials | Best for thin metal sheets and similar conductive materials. | Suitable for a wide range of metals and thicknesses. |

| Applications | Automotive, electronics, appliance manufacturing. | Construction, repair, custom fabrication. |

| Equipment Cost | Higher initial investment due to automation and control systems. | Lower cost, simpler equipment with manual controls. |

Overview of Resistance Welding

Resistance welding utilizes electrical current and pressure to join metal surfaces by generating heat through electrical resistance at the interface. This process offers precise control over welding parameters, making it ideal for high-volume manufacturing and materials like sheet metal and wire mesh. Key advantages include rapid cycle times, minimal material distortion, and strong, consistent welds without the need for filler materials.

What is Semi-Automatic Welding?

Semi-automatic welding involves a process where the welder controls the torch or electrode movement while the machine feeds the filler material or controls the power source. It combines manual precision with mechanized support, enhancing efficiency and consistency compared to fully manual welding. Unlike resistance welding, which uses electrical resistance to generate heat and join metals, semi-automatic welding offers greater flexibility for various welding positions and materials.

Key Differences in Welding Processes

Resistance welding uses electric current and pressure to join metals through localized heat at the interface, enabling fast, consistent welds ideal for mass production. Semi-automatic welding involves manual control of the welding torch with automated wire feed, providing greater flexibility and precision for complex joints. The key difference lies in resistance welding's fully automated, high-speed process versus semi-automatic welding's operator-dependent control and adaptability.

Equipment and Tooling Comparison

Resistance welding equipment consists of electrodes, transformers, and controllers designed for precise heat generation through electrical resistance, ensuring efficient and consistent welds. Semi-automatic welding utilizes weld guns, wire feeders, and power sources that offer greater flexibility in welding positions and materials, adapting easily to complex geometries. Tooling for resistance welding emphasizes electrode customization for specific joint types, while semi-automatic welding tooling involves interchangeable nozzles and welding wires tailored for diverse applications.

Applications and Common Uses

Resistance welding is widely used in automotive manufacturing, electronics assembly, and metal furniture production due to its high-speed operation and strong, consistent welds on sheet metals and wire components. Semi-automatic welding finds common applications in construction, shipbuilding, and pipeline work where versatility and operator control allow for welding thicker materials and complex joints. Both techniques serve distinct industrial needs, with resistance welding excelling in mass production and semi-automatic welding favored for customized or heavy-duty fabrication tasks.

Quality and Strength of Welds

Resistance welding produces high-quality welds with consistent strength due to precise control of heat and pressure, minimizing defects such as porosity and weak joints. Semi-automatic welding, while offering flexibility for varied applications, may result in variable weld quality and strength depending on operator skill and environmental factors. The uniformity and repeatability of resistance welding make it ideal for applications demanding reliable and robust weld integrity.

Cost Implications and Efficiency

Resistance welding offers lower operational costs due to minimal consumable use and faster cycle times, making it highly efficient for high-volume production. Semi-automatic welding involves higher labor costs and slower throughput but provides greater flexibility for complex or variable welds. Cost implications lean towards resistance welding in mass production scenarios, while semi-automatic welding suits customized or small-batch projects requiring precision.

Safety Considerations in Both Methods

Resistance welding offers enhanced safety by minimizing operator exposure to molten metal and open flames, reducing burn and fire hazards. Semi-automatic welding requires stricter adherence to protective gear and ventilation protocols due to increased risks of fumes, sparks, and UV radiation exposure. Both methods demand comprehensive training and implementation of safety standards to mitigate potential electrical shocks and mechanical injuries.

Skill Requirements and Training

Resistance welding requires minimal operator skill due to its automated process and precise control systems, allowing for consistent weld quality with basic training. Semi-automatic welding demands higher operator expertise to manually control the welding parameters, torch angle, and travel speed, necessitating extensive training and experience for proficient execution. Proper training in semi-automatic welding covers equipment handling, safety protocols, and welding techniques, while resistance welding training primarily emphasizes machine setup and maintenance.

Choosing the Right Welding Method

Resistance welding offers high-speed, automated processes ideal for mass production with consistent quality, making it suitable for thin metals and repetitive tasks. Semi-automatic welding provides greater control and versatility, allowing operators to adjust parameters for complex joints and varied materials, which is beneficial in custom fabrication and repair work. Selecting the right welding method depends on production volume, material thickness, precision requirements, and the complexity of weld joints to optimize efficiency and quality.

Resistance welding Infographic

libterm.com

libterm.com