Stiffness refers to the resistance of an object or material to deformation under applied force, playing a crucial role in engineering, biomechanics, and materials science. Understanding how stiffness affects structural integrity and performance helps in designing durable and efficient products that meet specific functional requirements. Explore the rest of this article to learn how optimizing stiffness can enhance your designs and applications.

Table of Comparison

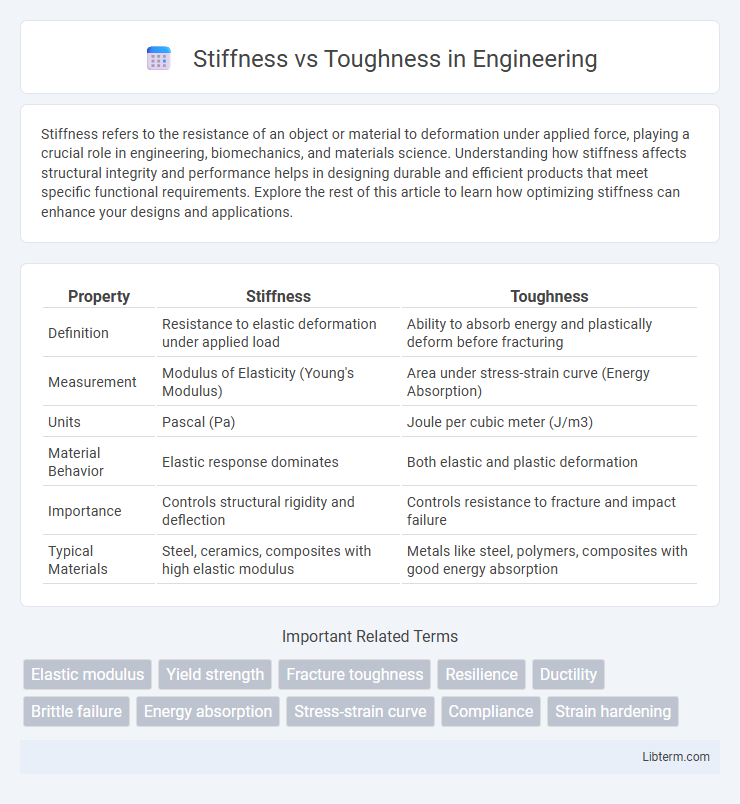

| Property | Stiffness | Toughness |

|---|---|---|

| Definition | Resistance to elastic deformation under applied load | Ability to absorb energy and plastically deform before fracturing |

| Measurement | Modulus of Elasticity (Young's Modulus) | Area under stress-strain curve (Energy Absorption) |

| Units | Pascal (Pa) | Joule per cubic meter (J/m3) |

| Material Behavior | Elastic response dominates | Both elastic and plastic deformation |

| Importance | Controls structural rigidity and deflection | Controls resistance to fracture and impact failure |

| Typical Materials | Steel, ceramics, composites with high elastic modulus | Metals like steel, polymers, composites with good energy absorption |

Introduction to Stiffness and Toughness

Stiffness measures a material's resistance to deformation under applied force, typically quantified by the modulus of elasticity or Young's modulus. Toughness represents a material's ability to absorb energy and plastically deform without fracturing, combining strength and ductility in its assessment. Understanding the distinction between stiffness and toughness is crucial for selecting materials that balance rigidity with the capacity to withstand impact or stress.

Defining Stiffness in Materials Science

Stiffness in materials science refers to a material's ability to resist deformation under an applied load, quantified by the modulus of elasticity or Young's modulus. It represents the ratio of stress to strain within the elastic limit, indicating how much a material will flex or bend when force is applied. Higher stiffness values signify materials that maintain shape and exhibit minimal deformation, essential for structural applications requiring rigidity.

Understanding Toughness: Key Concepts

Toughness represents a material's ability to absorb energy and plastically deform without fracturing, measured by the area under the stress-strain curve during testing. Unlike stiffness, which quantifies resistance to elastic deformation via Young's modulus, toughness reflects both strength and ductility, capturing energy absorption capacity before failure. Key concepts in understanding toughness include fracture toughness, impact toughness, and the material's ability to resist crack propagation under dynamic or sudden loads.

Stiffness vs Toughness: Core Differences

Stiffness measures a material's resistance to elastic deformation under applied force, quantified by its modulus of elasticity, while toughness represents the ability to absorb energy and deform plastically before fracturing. Stiff materials resist bending and maintain shape under stress, but may be brittle, whereas tough materials withstand impact and prevent sudden failure due to their energy absorption capacity. The core difference lies in stiffness relating to rigidity and shape retention, whereas toughness involves durability and fracture resistance under dynamic loading.

Measurement Methods for Stiffness

Stiffness is primarily measured using methods such as tensile testing, where the stress-strain curve provides the modulus of elasticity or Young's modulus, indicating resistance to deformation. Dynamic mechanical analysis (DMA) offers frequency-dependent stiffness values by applying oscillatory forces and measuring material response. Instrumented indentation testing, including nanoindentation, evaluates local stiffness by recording force-displacement data during indentation on small or thin specimens.

Testing Techniques for Toughness

Toughness testing techniques primarily involve impact tests such as Charpy and Izod, which measure a material's ability to absorb energy during fracture. Fracture toughness tests, including crack tip opening displacement (CTOD) and stress intensity factor (K_IC) methods, evaluate resistance to crack propagation under stress. These techniques provide critical data for assessing material performance in applications subjected to sudden or dynamic loads.

Material Examples: Stiffness vs Toughness

Steel exhibits high stiffness with a Young's modulus around 200 GPa, making it resistant to elastic deformation, while its toughness is moderate due to its ability to absorb energy before fracturing. In contrast, rubber has low stiffness but exceptional toughness, characterized by its large strain capacity and energy absorption during deformation. Materials like ceramics demonstrate very high stiffness but low toughness, as they fracture easily under stress despite minimal elastic deformation.

Real-World Applications and Implications

Stiffness determines a material's ability to resist deformation under load, crucial in construction and aerospace for maintaining structural integrity and precision. Toughness measures a material's capacity to absorb energy and resist fracture, essential in automotive safety components and protective gear where impact resistance is critical. Understanding the balance between stiffness and toughness guides engineers in selecting materials that optimize performance and durability in real-world applications.

Factors Affecting Stiffness and Toughness

Stiffness is primarily influenced by material composition, molecular structure, and cross-sectional area, with metals and ceramics typically exhibiting higher stiffness due to strong atomic bonds and rigid lattice structures. Toughness depends on a material's ability to absorb energy before fracturing, which is affected by factors such as ductility, temperature, grain size, and presence of microstructural defects, with polymers and composites often displaying greater toughness. Both properties are crucial in engineering applications, where optimizing alloying elements, heat treatment, and processing methods can tailor stiffness and toughness to meet specific performance requirements.

Choosing the Right Property for Engineering Design

Stiffness measures a material's resistance to deformation under applied force, critical for maintaining shape and structural integrity in precision engineering applications. Toughness quantifies a material's ability to absorb energy and resist fracture, essential in designs subjected to impact or dynamic loads. Selecting the appropriate property depends on the application's demands: stiffness prioritizes rigidity and dimensional stability, while toughness ensures durability and resistance to crack propagation.

Stiffness Infographic

libterm.com

libterm.com