Axial loading refers to a force applied along the longitudinal axis of a structural member, causing tension or compression without bending effects. This type of load is fundamental in engineering as it directly affects the strength and stability of columns, beams, and other components under load. Explore the article to understand how axial loading influences design and material choices in construction and engineering projects.

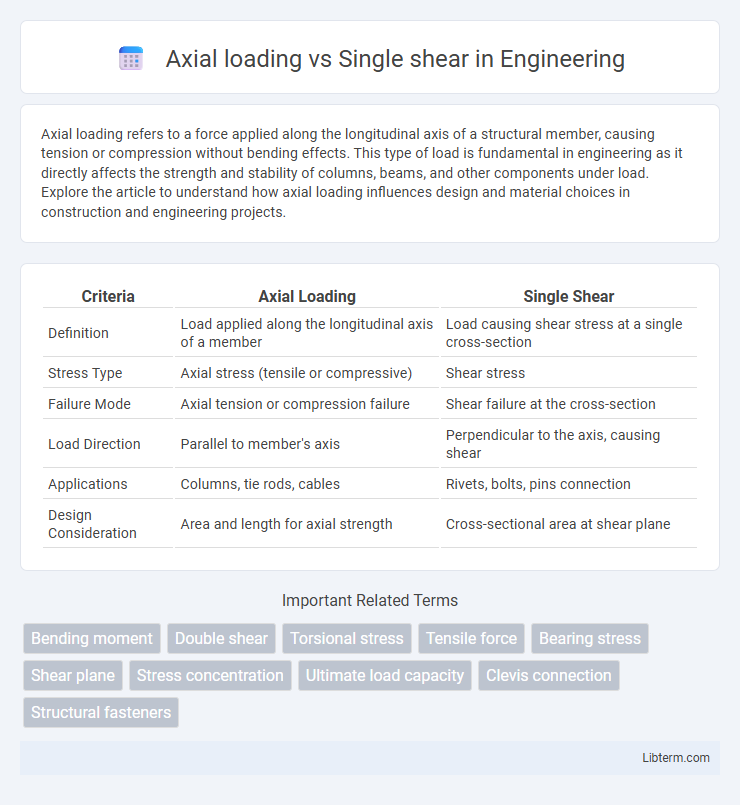

Table of Comparison

| Criteria | Axial Loading | Single Shear |

|---|---|---|

| Definition | Load applied along the longitudinal axis of a member | Load causing shear stress at a single cross-section |

| Stress Type | Axial stress (tensile or compressive) | Shear stress |

| Failure Mode | Axial tension or compression failure | Shear failure at the cross-section |

| Load Direction | Parallel to member's axis | Perpendicular to the axis, causing shear |

| Applications | Columns, tie rods, cables | Rivets, bolts, pins connection |

| Design Consideration | Area and length for axial strength | Cross-sectional area at shear plane |

Introduction to Axial Loading and Single Shear

Axial loading refers to the application of a force along the longitudinal axis of a structural member, causing tension or compression that affects the entire cross-sectional area uniformly. Single shear occurs when a force causes a material or fastener to experience stress along a single plane, typically seen in scenarios like bolted connections where the load tries to slide one part relative to another. Understanding the difference between axial loading and single shear is critical for material selection and design in structural engineering to ensure safety and performance under various load conditions.

Defining Axial Loading

Axial loading refers to the application of a force along the longitudinal axis of a structural member, causing tension or compression within the material. This load type induces uniform stress distribution across the cross-section, essential for evaluating structural integrity and load-bearing capacity. In contrast, single shear involves forces acting parallel to a plane, creating shear stress that tends to slide material layers relative to each other.

Understanding Single Shear

Single shear involves a force applied perpendicular to a material, causing it to experience stress along a single plane, often used to evaluate the strength of fasteners like bolts. Axial loading applies force along the longitudinal axis, inducing tension or compression, but single shear focuses on the material's resistance across one shear plane. Understanding single shear is crucial for designing joints and connections where shear forces dominate, ensuring the structural integrity of mechanical assemblies.

Key Differences Between Axial Loading and Single Shear

Axial loading involves forces applied along the longitudinal axis of a structural member, resulting in uniform stress distribution, while single shear occurs when a force is applied perpendicular to the member, causing a shearing effect along a single plane. Axial loading primarily induces tensile or compressive stress, whereas single shear generates shear stress concentrated at the cross-sectional area where the force acts. Understanding these differences is crucial for designing structural components, as axial loading tests material strength in tension or compression, and single shear tests material's resistance to sliding failure.

Stress Distribution in Axial Loading

In axial loading, stress distribution is uniform across the cross-sectional area, resulting in consistent normal stress throughout the member. Single shear involves stress concentration at the shear plane, producing a non-uniform shear stress distribution localized around the interface. Axial loading ensures optimal load transfer by minimizing stress gradients, which contrasts with the concentrated stresses observed in single shear connections.

Shear Force Mechanics Explained

Axial loading subjects a structural element to forces along its longitudinal axis, primarily inducing tensile or compressive stress, whereas single shear involves forces acting perpendicular to the axis, creating a shear force that tends to cause sliding failure along a plane. Shear force mechanics in single shear focus on the internal resistance generated by molecular bonds between adjacent material layers, quantified by the shear stress equation t = F / A, where F is the shear force and A is the cross-sectional area resisting the force. Understanding the difference between axial and shear stresses is critical for analyzing load-bearing capacity and preventing structural failure in engineering applications.

Common Applications of Axial Loading

Axial loading is commonly applied in structural columns, bridges, and mechanical shafts where forces act along the member's longitudinal axis to ensure stability and load transfer. It plays a critical role in construction and machinery, supporting compressive or tensile forces without inducing bending. In contrast, single shear typically occurs in fasteners and joints subjected to transverse forces, making axial loading essential for components designed to bear direct compressive or tensile stresses.

Typical Uses of Single Shear in Engineering

Single shear is commonly used in mechanical and structural engineering applications where a pin or bolt connects two components, subjecting the connection to shear forces. Typical uses include fastening components in machinery, automotive assemblies, and light structural frameworks where the load is applied perpendicular to the pin axis. Single shear connections offer simpler design and inspection compared to axial loading scenarios, making them ideal for applications with moderate load requirements and easier maintenance access.

Material Selection for Axial and Shear Loads

Material selection for axial loading prioritizes high tensile strength and ductility to withstand direct compressive or tensile forces without deformation or failure. For single shear scenarios, materials with superior shear strength and toughness are essential to resist sliding failure along the shear plane. Steel alloys such as high-strength carbon steels excel in axial loading applications, while toughened alloys or composite materials are often preferred for single shear due to their enhanced shear resistance and fatigue performance.

Design Considerations: Safety and Efficiency

Axial loading demands design that maximizes load-bearing capacity and ensures uniform stress distribution to prevent buckling and failure. Single shear connections require precise calculation of shear stress and selection of appropriate fasteners to resist shear forces without excessive deformation. Prioritizing safety involves incorporating factors of safety and material properties, while efficiency hinges on optimized cross-sectional areas and minimal material usage.

Axial loading Infographic

libterm.com

libterm.com