Rigidity modulus, also known as shear modulus, measures a material's resistance to deformation under shear stress. This property plays a crucial role in determining how materials respond to forces that cause layers to slide against each other. Explore the full article to understand how your materials perform under different stress conditions.

Table of Comparison

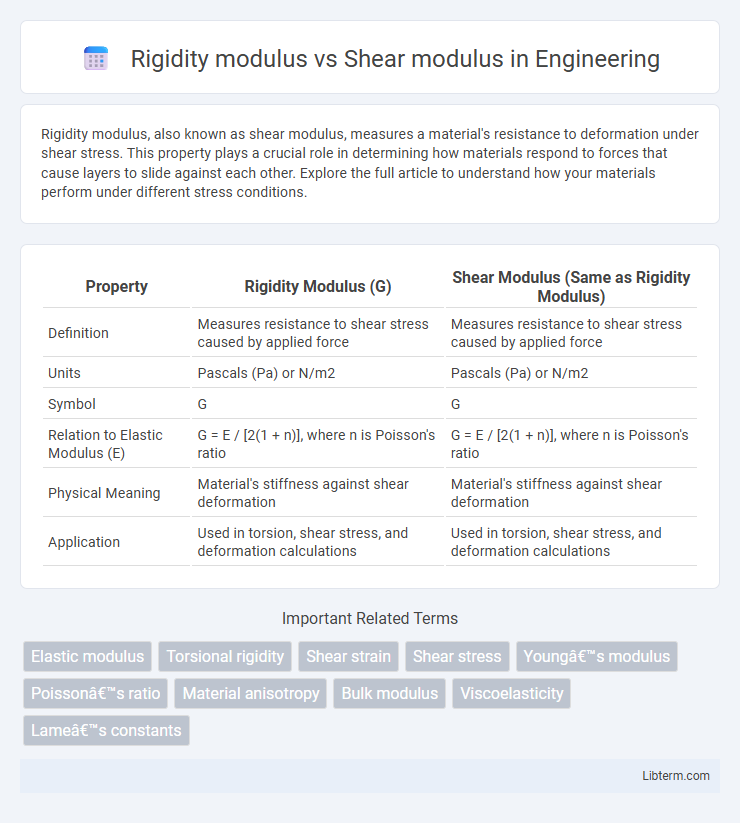

| Property | Rigidity Modulus (G) | Shear Modulus (Same as Rigidity Modulus) |

|---|---|---|

| Definition | Measures resistance to shear stress caused by applied force | Measures resistance to shear stress caused by applied force |

| Units | Pascals (Pa) or N/m2 | Pascals (Pa) or N/m2 |

| Symbol | G | G |

| Relation to Elastic Modulus (E) | G = E / [2(1 + n)], where n is Poisson's ratio | G = E / [2(1 + n)], where n is Poisson's ratio |

| Physical Meaning | Material's stiffness against shear deformation | Material's stiffness against shear deformation |

| Application | Used in torsion, shear stress, and deformation calculations | Used in torsion, shear stress, and deformation calculations |

Introduction to Rigidity Modulus and Shear Modulus

Rigidity modulus, also known as shear modulus, quantifies a material's resistance to shear deformation under applied forces. It is defined as the ratio of shear stress to shear strain, reflecting the material's ability to maintain shape when subjected to tangential loads. This fundamental mechanical property is critical in engineering applications for assessing material stiffness and predicting elastic behavior under shear stresses.

Defining Rigidity Modulus

Rigidity modulus, also known as shear modulus, defines a material's ability to resist deformation under shear stress, quantifying the ratio of shear stress to shear strain. This modulus is essential in characterizing the elastic behavior of materials like metals, polymers, and composites when subjected to tangential forces. Values of rigidity modulus are critical for designing structures and mechanical components that must withstand torsional and shear loads without permanent deformation.

Understanding Shear Modulus

Shear modulus, also known as rigidity modulus, measures a material's resistance to shear deformation under applied force. It quantifies the ratio of shear stress to shear strain in elastic materials and is crucial for analyzing mechanical behavior in structural engineering. High shear modulus values indicate materials with greater rigidity and less susceptibility to shape changes under shear stress.

Rigidity Modulus vs Shear Modulus: Key Differences

Rigidity modulus, also known as shear modulus, measures a material's resistance to shear deformation by quantifying the ratio of shear stress to shear strain. While both terms describe the same mechanical property, "rigidity modulus" emphasizes the material's stiffness against shape changes, whereas "shear modulus" is commonly used in engineering and physics contexts. Key differences include variations in terminology across disciplines, but numerically and conceptually, rigidity modulus and shear modulus are equivalent metrics defining a material's ability to withstand shear forces.

Similarities Between Rigidity Modulus and Shear Modulus

Rigidity modulus and shear modulus both describe a material's resistance to deformation under shear stress, quantifying how it withstands shape changes without volume alteration. These moduli share identical units, typically pascals (Pa), and often represent the same physical property in isotropic materials, making them interchangeable in many engineering contexts. Both are essential parameters in elasticity theory, characterizing the mechanical behavior of solids under applied forces.

Mathematical Expression and Units

Rigidity modulus (G) and shear modulus refer to the same physical property describing a material's response to shear stress, mathematically expressed as G = t/g, where t is shear stress and g is shear strain. Both terms share identical SI units of pascals (Pa), reflecting force per unit area (N/m2). Differences in terminology arise primarily from context rather than mathematical definition or unit representation.

Practical Applications in Engineering

Rigidity modulus, also known as shear modulus, is critical in engineering for analyzing material deformation under shear stress, ensuring structural stability in buildings, bridges, and machinery. It helps engineers design components that resist torsional forces, such as shafts, beams, and fasteners, by predicting how materials twist or bend under load. Accurate knowledge of this modulus enables optimized material selection and enhances safety and durability in mechanical and civil engineering projects.

Factors Affecting Shear and Rigidity Modulus

Shear modulus and rigidity modulus are terms often used interchangeably to describe a material's resistance to shear deformation, both influenced by factors such as temperature, material composition, and microstructural changes. Temperature increases typically reduce these moduli by enhancing atomic vibrations and dislocation movements, while alloying elements and heat treatments can improve their values by altering crystal structure and grain size. The presence of defects, impurities, and strain rates also significantly impact the shear and rigidity modulus, affecting the material's elastic response under stress.

Experimental Measurement Methods

Rigidity modulus and shear modulus are often used interchangeably, both representing a material's resistance to shear deformation, but subtle differences may arise in specific contexts. Experimental measurement methods for these moduli primarily include torsion tests, where a cylindrical specimen is twisted to determine torque and angle of twist; and ultrasonic testing, which measures shear wave velocities to calculate the shear modulus non-destructively. Precise calibration of instruments and controlled environmental conditions ensure accurate determination of the rigidity modulus and shear modulus during these experimental procedures.

Summary: Choosing the Right Modulus for Analysis

Rigidity modulus and shear modulus often refer to the same material property, quantifying resistance to shear deformation under applied forces. Selecting the appropriate term depends on regional preferences and calculation context, with shear modulus commonly used in engineering mechanics and rigidity modulus appearing in materials science literature. Understanding their equivalence ensures accurate analysis of stress-strain relationships in solids for effective design and material evaluation.

Rigidity modulus Infographic

libterm.com

libterm.com