Line load refers to the amount of electrical power transmitted through a single power line or cable, typically measured in amperes or watts per meter. Properly managing line load is crucial to prevent overheating, ensure system stability, and avoid power outages in electrical grids. Explore the rest of this article to learn how effective line load management can optimize your electrical system's performance.

Table of Comparison

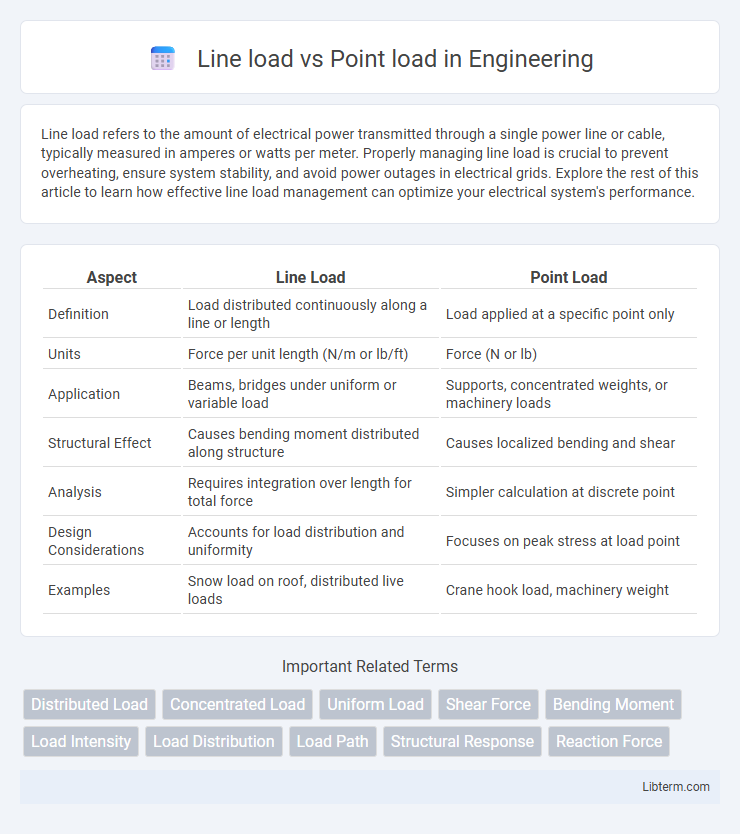

| Aspect | Line Load | Point Load |

|---|---|---|

| Definition | Load distributed continuously along a line or length | Load applied at a specific point only |

| Units | Force per unit length (N/m or lb/ft) | Force (N or lb) |

| Application | Beams, bridges under uniform or variable load | Supports, concentrated weights, or machinery loads |

| Structural Effect | Causes bending moment distributed along structure | Causes localized bending and shear |

| Analysis | Requires integration over length for total force | Simpler calculation at discrete point |

| Design Considerations | Accounts for load distribution and uniformity | Focuses on peak stress at load point |

| Examples | Snow load on roof, distributed live loads | Crane hook load, machinery weight |

Understanding Line Load and Point Load

Line load refers to a force distributed uniformly or variably along a length, commonly measured in units like Newtons per meter (N/m), essential for analyzing beams and structural elements. Point load is a concentrated force applied at a single location on a structure, characterized by its magnitude in Newtons (N), critical for determining stress and deflection. Understanding the distinction between line load and point load ensures accurate calculations in structural engineering, influencing design efficiency and safety.

Fundamental Differences Between Line Load and Point Load

Line load distributes force continuously along a length on a structural element, measured in units like Newtons per meter (N/m), whereas point load applies force at a specific location, quantified in Newtons (N). Line loads induce bending moments and shear forces spread over a span, resulting in uniform stress distribution, while point loads create concentrated reactions and localized stresses at the application point. Understanding these fundamental differences is crucial for accurate structural analysis and design in beams, bridges, and similar frameworks.

Basic Definitions: What Is a Line Load?

A line load is a type of structural load distributed along a length, typically measured in force per unit length (N/m or lbs/ft). It represents forces acting continuously over a beam or wall, unlike a point load which is concentrated at a specific location. Line loads are fundamental in analyzing bending moments and shear forces in structural engineering applications.

Basic Definitions: What Is a Point Load?

A point load refers to a concentrated force applied at a specific, singular location on a structure, causing localized stress and deformation. It differs from a line load, which is distributed continuously along a length or edge of a structural element. Point loads are critical in structural analysis as they help determine stress concentrations and deflection at targeted points in beams or frames.

Applications of Line Loads in Structural Engineering

Line loads are frequently applied in structural engineering to model distributed forces such as the weight of walls on beams, floor loads on supporting girders, and load from suspended ceilings. These loads enable accurate analysis of structural elements under uniform or varying pressures along their length, crucial for designing beams, slabs, and retaining walls. Utilizing line load representations improves safety and efficiency in civil structures by ensuring realistic load distributions are considered in load-bearing designs.

Applications of Point Loads in Structural Engineering

Point loads in structural engineering are applied at specific, concentrated locations on a structure, enabling precise analysis of stress and deflection at critical points such as beam supports, column bases, and connection joints. These loads are essential in designing structural elements that must withstand localized forces from heavy equipment, machinery, or concentrated weights in buildings and bridges. Unlike line loads, which distribute force along a length, point loads demand detailed evaluation to ensure safety and stability in areas prone to high stress concentration.

Calculation Methods for Line Loads

Calculation methods for line loads involve distributing the total load evenly or variably along the length of the structure, requiring integration to determine shear forces and bending moments at specific points. Engineers use formulas derived from the principles of static equilibrium, such as \( V = \int w(x) dx \) for shear force and \( M = \int V(x) dx \) for bending moment, where \( w(x) \) represents the line load intensity as a function of position. These methods contrast with point load calculations, which focus on discrete forces applied at singular locations, simplifying the mathematical approach to direct force and moment summations.

Calculation Methods for Point Loads

Point load calculation methods focus on determining the concentrated force applied at a specific location on a structure, commonly using formulas derived from static equilibrium principles. The calculation involves analyzing bending moments and shear forces at the point of application, often employing equations such as \( M = P \times a \) where \( P \) is the point load and \( a \) the distance from the support. Unlike line loads which are distributed over a length, point load analysis requires precise identification of load magnitude and exact position to ensure accurate stress and deflection estimations.

Effects on Structural Behavior: Line Load vs Point Load

Line loads distribute force evenly along a length, resulting in bending moments and shear forces that are more gradually spread across structural elements such as beams or slabs, reducing localized stresses and potential for failure. Point loads concentrate force at a single location, creating high stress concentrations and inducing significant bending moments and shear forces precisely at the application point, which can lead to localized deformation or cracking. Understanding the differences in load application is critical for designing structural components to withstand maximum expected stresses without compromising stability or safety.

Practical Examples: Choosing Line Loads or Point Loads

Choosing between line loads and point loads depends on structural application and load distribution characteristics. Line loads are ideal for supporting walls or beams where weight spreads over a length, such as roofing beams carrying uniform snow loads. Point loads are more suitable for concentrated forces like machinery legs or columns where load is applied at a specific location.

Line load Infographic

libterm.com

libterm.com