Indicated mean effective pressure (IMEP) measures the average pressure exerted on the piston during the combustion phase in an engine cylinder, reflecting its efficiency and performance. Understanding IMEP helps diagnose engine health and optimize fuel consumption by analyzing the pressure generated during the power stroke. Discover how IMEP impacts your engine's efficiency and how to use it for accurate performance assessments in the rest of this article.

Table of Comparison

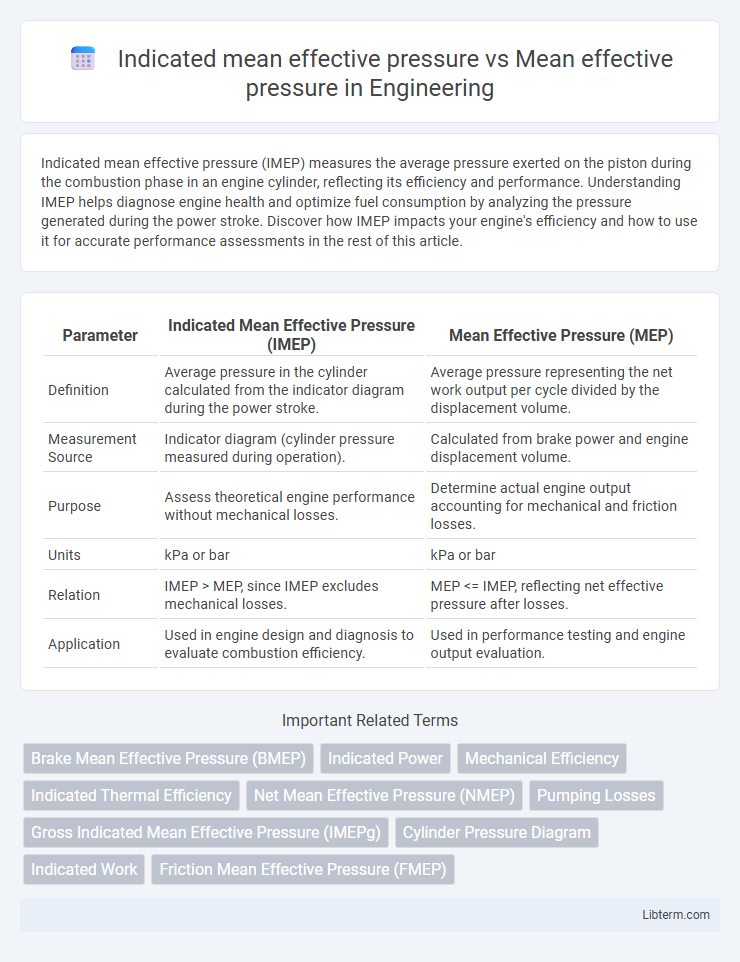

| Parameter | Indicated Mean Effective Pressure (IMEP) | Mean Effective Pressure (MEP) |

|---|---|---|

| Definition | Average pressure in the cylinder calculated from the indicator diagram during the power stroke. | Average pressure representing the net work output per cycle divided by the displacement volume. |

| Measurement Source | Indicator diagram (cylinder pressure measured during operation). | Calculated from brake power and engine displacement volume. |

| Purpose | Assess theoretical engine performance without mechanical losses. | Determine actual engine output accounting for mechanical and friction losses. |

| Units | kPa or bar | kPa or bar |

| Relation | IMEP > MEP, since IMEP excludes mechanical losses. | MEP <= IMEP, reflecting net effective pressure after losses. |

| Application | Used in engine design and diagnosis to evaluate combustion efficiency. | Used in performance testing and engine output evaluation. |

Introduction to Mean Effective Pressure (MEP)

Mean Effective Pressure (MEP) quantifies the average pressure in an engine cylinder during the power stroke, serving as a key indicator of engine performance and efficiency. Indicated Mean Effective Pressure (IMEP) specifically measures the pressure calculated from the cylinder pressure data without accounting for mechanical losses, reflecting the ideal engine work output. Comparing IMEP with Brake Mean Effective Pressure (BMEP) helps engineers analyze engine friction and mechanical efficiency for optimization.

Defining Indicated Mean Effective Pressure (IMEP)

Indicated Mean Effective Pressure (IMEP) represents the average pressure calculated from the engine's cylinder pressure data during the combustion cycle, reflecting the work output without mechanical losses. It differs from Mean Effective Pressure (MEP), which generally refers to brake MEP (BMEP) and includes the effects of mechanical friction and pumping losses, representing the net usable pressure at the crankshaft. IMEP is a crucial parameter for assessing the combustion efficiency and performance potential of internal combustion engines independently of mechanical efficiencies.

The Significance of MEP in Engine Performance

Mean Effective Pressure (MEP) is a critical metric in engine performance evaluation, representing the average pressure exerted on the piston during the power stroke. Indicated Mean Effective Pressure (IMEP) specifically measures the pressure derived from the combustion process within the cylinder, excluding mechanical losses, thus providing insight into the engine's combustion efficiency. Understanding IMEP versus MEP enables precise assessment of engine power output and thermodynamic efficiency, guiding optimization in design and tuning for enhanced fuel economy and reduced emissions.

Distinguishing IMEP from MEP

Indicated mean effective pressure (IMEP) measures the average pressure in the cylinder based on the indicated work done on the piston, excluding mechanical losses, whereas mean effective pressure (MEP) accounts for net work output after subtracting frictional and mechanical losses. IMEP is derived from pressure-volume diagrams obtained through cylinder pressure sensors, reflecting the actual combustion process efficiency independent of engine friction. MEP represents the effective pressure that contributes to shaft power, integrating losses and providing a more practical evaluation of engine performance.

Calculation Methods for IMEP and MEP

Indicated Mean Effective Pressure (IMEP) is calculated from the pressure data inside the cylinder, obtained via in-cylinder pressure sensors, by integrating the indicated work over the engine cycle and dividing it by the cylinder volume swept during the cycle. Mean Effective Pressure (MEP) is derived from the net work output measured at the crankshaft, divided by the swept volume, typically using torque and engine speed data from a dynamometer. IMEP calculation requires detailed pressure trace analysis while MEP relies on external engine performance measurements, both providing crucial metrics for engine efficiency evaluation.

Factors Affecting Both IMEP and MEP

Indicated mean effective pressure (IMEP) and mean effective pressure (MEP) are crucial metrics in evaluating engine performance, with IMEP representing the theoretical pressure generated within the combustion chamber and MEP reflecting the net usable pressure after mechanical losses. Factors affecting both IMEP and MEP include fuel-air mixture composition, ignition timing, engine speed, and valve timing, which influence the combustion efficiency and pressure generation. Additionally, frictional losses, heat transfer to the cylinder walls, and pumping losses significantly impact MEP, reducing it below the IMEP value.

Applications of IMEP and MEP in Engine Analysis

Indicated Mean Effective Pressure (IMEP) reflects the actual pressure generated inside an engine cylinder during the combustion process, serving as a critical parameter for assessing engine performance and combustion efficiency. Mean Effective Pressure (MEP), derived from external measurements, helps evaluate the overall engine torque and power output, facilitating comparisons across different engine designs and operating conditions. In engine analysis, IMEP is primarily used to diagnose combustion quality and identify losses within the cylinder, while MEP aids in optimizing engine load, fuel consumption, and mechanical efficiency in practical applications.

Importance of IMEP vs MEP in Engine Diagnostics

Indicated Mean Effective Pressure (IMEP) provides insight into the actual pressure generated within the combustion chamber, reflecting combustion efficiency and engine performance without considering mechanical losses. Mean Effective Pressure (MEP) accounts for both indicated pressure and mechanical losses, representing the net output torque of the engine. Comparing IMEP and MEP enables precise diagnostics of internal engine conditions, identifying issues such as frictional losses, valve leakages, and combustion inefficiencies critical for optimizing engine health and fuel economy.

Limitations and Challenges in Measuring IMEP and MEP

Indicated mean effective pressure (IMEP) measurement relies on in-cylinder pressure data, which can be affected by sensor accuracy, heat transfer, and cylinder-to-cylinder variations, posing challenges in obtaining precise and consistent readings. Mean effective pressure (MEP) is typically derived from engine output torque, but it may not reflect the true combustion efficiency due to mechanical losses and friction not accounted for in the measurement. Both IMEP and MEP face limitations in transient conditions and dynamic engine operation, where rapid changes in load and speed hinder obtaining stable and representative pressure or torque values.

Summary: Choosing Between IMEP and MEP for Engine Optimization

Indicated Mean Effective Pressure (IMEP) measures the average pressure within the combustion chamber based on cylinder pressure data, representing the engine's actual work potential. Mean Effective Pressure (MEP) is a broader metric derived from output torque and displacement, reflecting overall engine performance including mechanical losses. Selecting IMEP enables precise combustion analysis for optimizing fuel efficiency and emission control, while MEP offers practical insights into net engine performance and mechanical efficiency during real-world operation.

Indicated mean effective pressure Infographic

libterm.com

libterm.com